Heavy Duty TAG - Wireless Sensor

Intelligent HD TAG measures condition data from chassis and rail track

Key Facts

What can Heavy Duty TAG - Wireless Sensor provide?

The Bluetooth® wireless sensor Heavy Duty TAG is the base of an intelligent condition monitoring system for various industrial applications. Acceleration and tilt can be recorded. With the HD TAG, for instance, rail operators can measure anomalies in wheel-rail contact, and then, detect the condition of driveline components and rail infrastructure.

Details

Technical Information

| Data transfer: | Bluetooth® Low Energy (2.4 GHz)

Sub1GHz ready (868 MHz) |

| Operating temperature: | -40°C to +70°C (DIN EN 50155 Class TX)

|

| Protection class: | IP65

|

| Compliance: | Qualification according to standards of the Rail Industry

CE WEEE |

| Battery: | 3 x Lithium primary batteries, 4 Ah each,

service life up to 5 years |

| Data memory: | 16 MB Flash

|

| Scope of functions: | Real-Time Clock (RTC)

3-axis accelerometer

Temperature sensor

Tilt sensor OTA (Over the Air) capable |

| Only available in the Infrastructure and Driveline Monitoring system |

Benefits

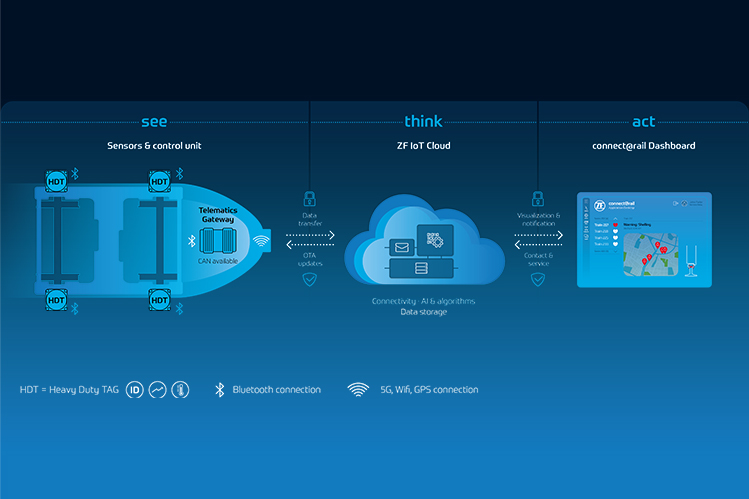

- Modular system of HD TAGs, Telematics Gateway and specific software packages, enables customized solutions for every application

- Comprehensive recording of condition data provides early insights regarding wear and damage

- Different, intelligent modes enable optimal measurement results, as well as maximum energy efficiency (service life: up to five years)

Function

Predictive Maintenance Planning with ZF Infrastructure and Driveline Monitoring

In the infrastructure and driveline monitoring system, the wireless sensor Heavy Duty TAG forms the basis for the condition monitoring of vehicle components and the rail infrastructure. The HD TAG can be mounted either on the transmission or the bogie.The recorded data is transmitted via Bluetooth® Low Energy to a Telematics Gateway (VCU Pro Onboard Unit). Afterwards, the acquired measurement and route data is processed and securely sent to the ZF IoT Cloud.Rail operators obtain up-to-date analysis results, which supports maintenance cycle planning, in order to improve condition, increase efficiency and avoid unplanned downtimes. Wear, damage and potential danger spots are then detected at an early stage.

Additional Information

Press release: ZF and Schunk sign Memorandum of Understanding for condition monitoring of power transmission systems

Press release: And Round it Goes: ZF Expands connect@rail to Include Monitoring Feature for Wheel-tread Wear

Press release: Partnerships With an (Eco)System: ZF Group Strategically Expands connect@rail Cooperation

Press release: Convincing All Along the Tram Line: Successful Start of the ZF Condition Monitoring System in Graz