Infrastructure and Driveline Monitoring System

Predictive maintenance planning for rail vehicles and infrastructure

Key Facts

What can Infrastructure and Driveline Monitoring System provide?

ZF's Infrastructure and Driveline Monitoring System is a turnkey connect@rail solution consisting of hardware, software, and associated platforms. The system is developed for independent and maintenance-free operation in rail vehicles. Operators benefit from up-to-date analysis results, which support maintenance cycle planning based on the condition, increase efficiency in rail transport, and avoid unplanned downtimes

Details

System

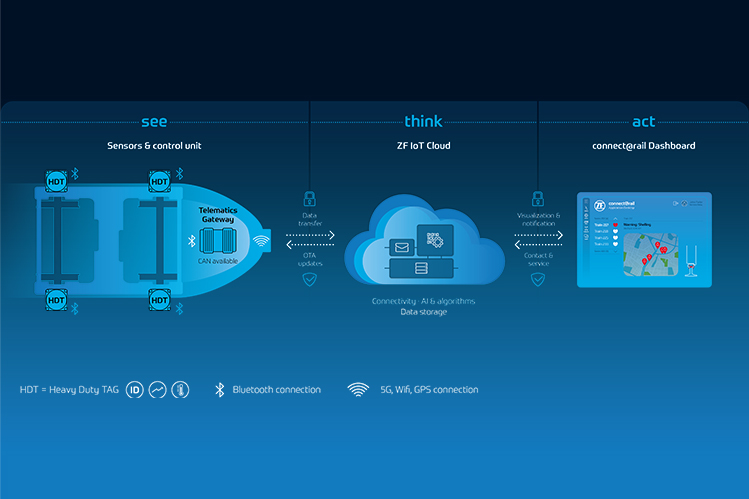

The wireless sensor Heavy Duty TAG forms the basis for the Infrastructure and Driveline Monitoring System. The sensors are mounted on the bogie of the rail vehicle and record data such as accelerations, vibrations and anomalies in wheel-rail contact. The recorded data is transmitted via Bluetooth® Low Energy to a telematics gateway, the VCU Pro Onboard Unit.

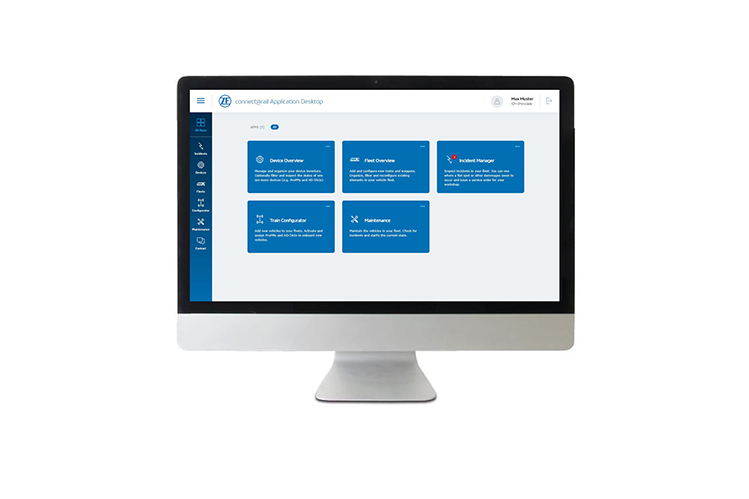

From there, the collected measurement and rail track data is processed and securely transferred to the ZF IoT Cloud. Operators can access the latest data from anywhere and at any time via a digital dashboard and thus obtain an overview of their fleet.

From there, the collected measurement and rail track data is processed and securely transferred to the ZF IoT Cloud. Operators can access the latest data from anywhere and at any time via a digital dashboard and thus obtain an overview of their fleet.

Features

Wheels

Damage to wheels, such as flat spots or microcracks on the wheel surface of rail vehicles, can have serious consequences for the vehicle, passengers and residents. For example, if the wheel no longer rolls gently over the rail, increased noise emissions and damage to the vehicle can result. With the help of the Infrastructure and Driveline Monitoring System, such wear can be detected at an early stage before immissions occur and reported to the operator via the dashboard.

Infrastructure

Due to weather fluctuations, peak utilization, and everyday wear, the rail network is under a lot of pressure. ZF's digital monitoring system aims to precisely and effectively record track condition so that potential damage can be identified at an early stage.

Driveline components

In the future, it will also be possible to digitally monitor driveline components, such as bearings, transmissions, and dampers, with the ZF Condition Monitoring solution.

Damage to wheels, such as flat spots or microcracks on the wheel surface of rail vehicles, can have serious consequences for the vehicle, passengers and residents. For example, if the wheel no longer rolls gently over the rail, increased noise emissions and damage to the vehicle can result. With the help of the Infrastructure and Driveline Monitoring System, such wear can be detected at an early stage before immissions occur and reported to the operator via the dashboard.

Infrastructure

Due to weather fluctuations, peak utilization, and everyday wear, the rail network is under a lot of pressure. ZF's digital monitoring system aims to precisely and effectively record track condition so that potential damage can be identified at an early stage.

Driveline components

In the future, it will also be possible to digitally monitor driveline components, such as bearings, transmissions, and dampers, with the ZF Condition Monitoring solution.

Additional information

Press release: ZF and Schunk sign Memorandum of Understanding for condition monitoring of power transmission systems

Press release: And Round it Goes: ZF Expands connect@rail to Include Monitoring Feature for Wheel-tread Wear

Press release: Partnerships With an (Eco)System: ZF Group Strategically Expands connect@rail Cooperation

Press release: Convincing All Along the Tram Line: Successful Start of the ZF Condition Monitoring System in Graz