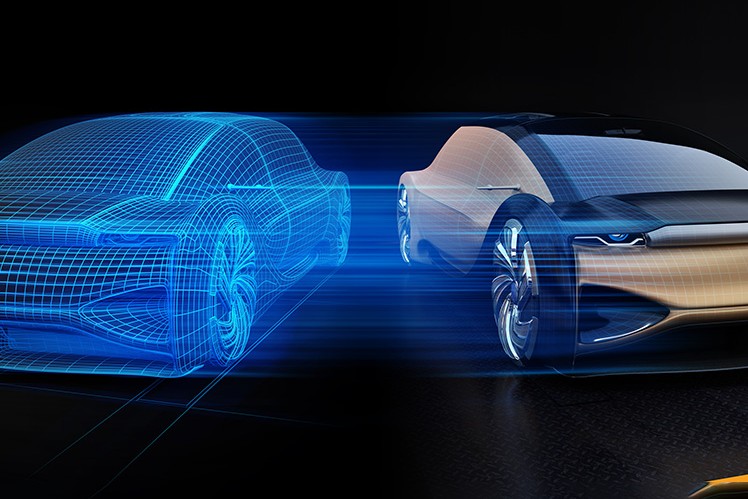

What is a Digital Twin?

A digital twin is a virtual image of a real object, system or process. It accompanies a product throughout its entire life cycle – from the initial idea through development and production to use, maintenance and finally recycling. This digital representation makes it possible to simulate, analyze and optimize real processes in a virtual environment. In addition, it can be used to optimize collaboration and develop new business models. Digital twins for products also provide greater transparency, traceability, and efficiency.

Why are Digital Twins so Important?

Digital twins are revolutionizing the way products are developed, manufactured and operated. They offer numerous advantages:

Where Does ZF Use the Digital Twin?

ZF uses digital twins along the entire product life cycle - from the development of new functions and assistance systems to the optimization of production lines. Sustainability goals are also supported, for example by reducing energy consumption and waste volumes.

Digital twins do not completely replace physical tests, they complement them. Their informative value depends heavily on the quality of the input data and calibration with real scenarios. ZF relies on consistent data models, precise measurements and strict validation processes to ensure reliable results.

A look into the future shows that artificial intelligence and machine learning are increasingly being integrated to enable even more precise predictions. In addition, networking with platforms such as Catena-X is being driven forward in order to achieve end-to-end data integration along the entire automotive value chain.

How are Digital Twins Changing Processes in Development and Testing?

Digital twins can shorten development times, reduce costs and increase product quality. They also increase efficiency and thus competitiveness.

What are the Advantages of Digital Twins in Production?

In the digital age, the planning of a production plant takes place virtually. A digital twin of the planned system not only contains the dimensions of the individual components, but also their performance data, behavior, interfaces and much more. It also provides data that enables precise predictions to be made as to the effect of a change at a different location, for example.