Virtual Journey Into Reality

Virtual development is inextricably linked to mobility’s transformation. Greater digitization of this critical process step is essential for suppliers like ZF to consistently meet customer expectations for speed and quality. Here’s an overview.

“Panta rhei”, ancient Greek for “everything flows”, is a saying attributed to philosopher Heraclitus. This aphorism from the fifth century BC still applies today. Evidence of this can also be found in automotive history. After more than a century in which the combustion engine dominated, the industry and society have been undergoing a transformation where electrification, digitalization and autonomous driving are fundamentally changing mobility. Added to this is intensifying competition, triggered primarily by Chinese manufacturers of electric cars. One of the consequences of these changes is shorter development cycles. As a result, development departments along the entire automotive value chain must work faster and more efficiently. Traditional development methods alone cannot meet this requirement.

Digitalization Is Essential

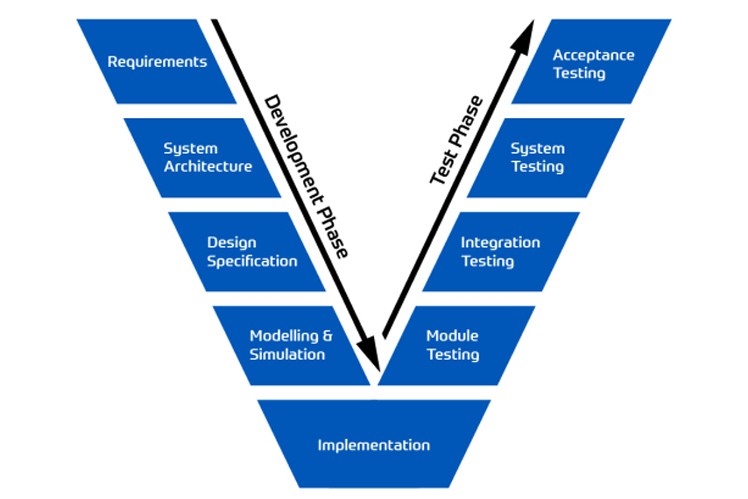

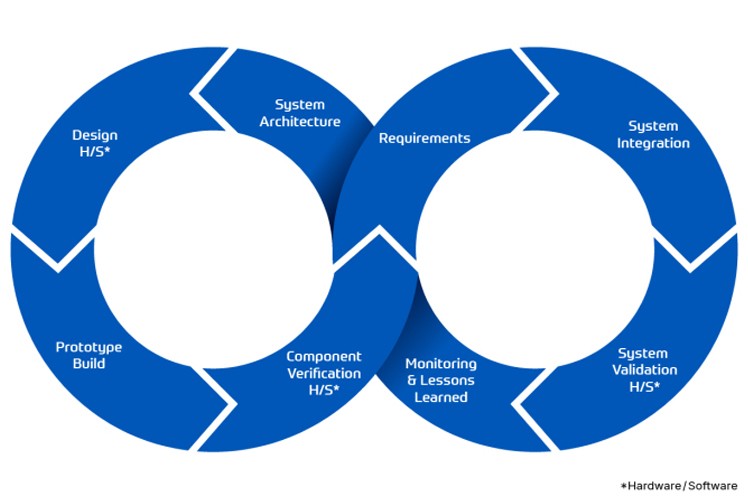

In general, the work of development engineers is shifting from the hardware-driven approach practiced for decades to a digitally driven one. New mobility, with its systems for electric drives, driver assistance systems and comprehensive networking, requires developers to have software, electronic and IT skills. It is the age of virtual development – an approach that relies on system engineering, digital twins and model-based requirements.

ZF is also pushing its virtual development efforts. Dr. Stefan Sicklinger summarized the advantages: “In virtual development, products are designed, evaluated, and optimized digitally. This allows requirements to be verified even before prototypes are built.” Stefan Sicklinger heads the AI, Digital Engineering, and Validation division within Central Research and Development. The greatest economic impact comes from the closed loop between simulation and physical testing: test results calibrate the models, and the models define the necessary tests.

Benefits of Virtual Development

Virtualization not only speeds up the development process but also offers other competitive advantages. It shortens the time-to-market, i.e., the period between the conception of an idea and the market launch of the resulting product. This time advantage is complemented by cost advantages, as many expensive physical prototypes can be replaced by digital prototypes. By using tools such as digital twins, developers can identify potential errors or mistakes earlier, thus avoiding costly missteps. Virtual development also facilitates collaboration with both customers and suppliers.

To reap these benefits, ZF virtualizes all phases of the development process including the request for quotation (RFQ) phase, system layout, design phase and validation.

ZF relies on digital product models as early as the quotation phase, also known as the RFQ phase, when a customer inquires about a new product. This allows the company to check feasibility and see what the product could look like. The result can then be coordinated with the customer. Before the virtual age, this step required the construction of a real prototype.

The construction plan for the product is created during the system layout phase. Weaknesses and errors can be corrected immediately and the function optimized. This saves a lot of time and money.

In the design phase, developers build and test the product virtually. ZF has a collection of digital tests for this purpose. Engineers use them to check whether their design works. These virtual prototypes significantly reduce the number of real prototypes required, which in turn shortens the development time considerably.

During validation, ZF combines virtual tests with classic tests of physical prototypes on the test bench. ZF calls this approach “hybrid release.” The technology group also uses artificial intelligence (AI) for this purpose. It analyzes data from previous projects and helps to develop the most efficient test strategy.

Indispensable: Digital Twins and Virtual Control Units

The digital twin is at the heart of virtual development. It is a 1:1 virtual copy of a product that can be tested and optimized on a computer long before the first test sample is built. In general, the use of software plays a decisive role in mechatronic systems, says Dr. Martin Obermayr, Manager at the Center of Competence Digital Twin.

In the future, the test environment will be virtual. ZF will then provide its customers with digital test benches on which functions can be tested automatically. This is a prerequisite for fast feedback, enables flexible adjustments, and improves cooperation with customers and suppliers. All of this contributes to keeping the transformation of mobility in flux.