110 Years of ZF

From Gear Specialist to Technology Group

How Time Flies! More than a century ago, three visionaries founded a company on Lake Constance that bore the simple name “Zahnradfabrik” (Gear Factory). Over the decades, this small transmission specialist evolved into a mobility group that has been known as “ZF Friedrichshafen AG” since 1992. As much as the world and ZF have changed, one thing has remained constant: our commitment to our products – always innovative, always of the highest quality.

Follow ZF’s rise over the past 110 years. We’ve highlighted the key milestones as “Milestones in ZF History.” Further down on this page, you’ll discover why the ZF site in Schweinfurt is celebrating its 130th anniversary this year.

Join us on an eventful journey through time and let our passion for mobility inspire you.

Milestones in ZF History

2024

ZF LIFETEC

ZF LIFETEC enables the electric locking of seat belts through e.Locking. This simplifies the integration of the belt into the seat, offering design and production advantages. During strong deceleration, the belt spool mechanically locks, preventing the belt from being pulled out or only against a force limiter. In an upright seating position, this combination reduces the impact of hard braking or accidents.

2024

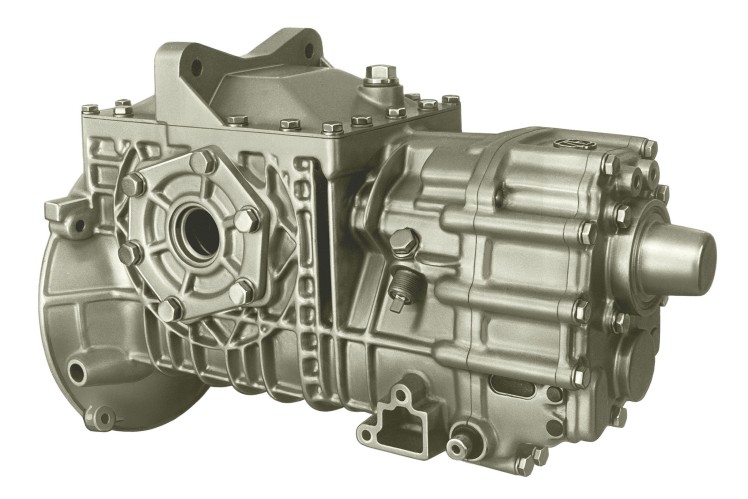

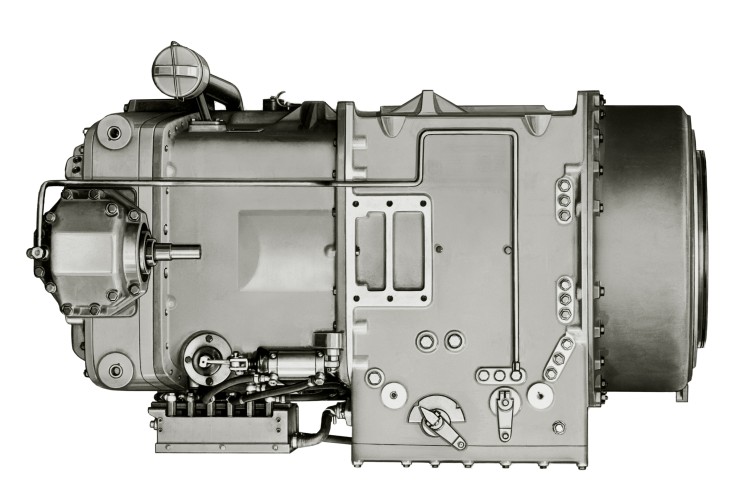

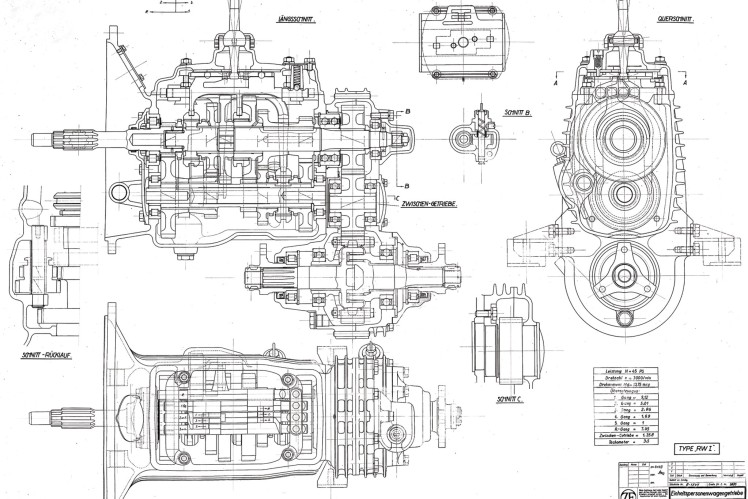

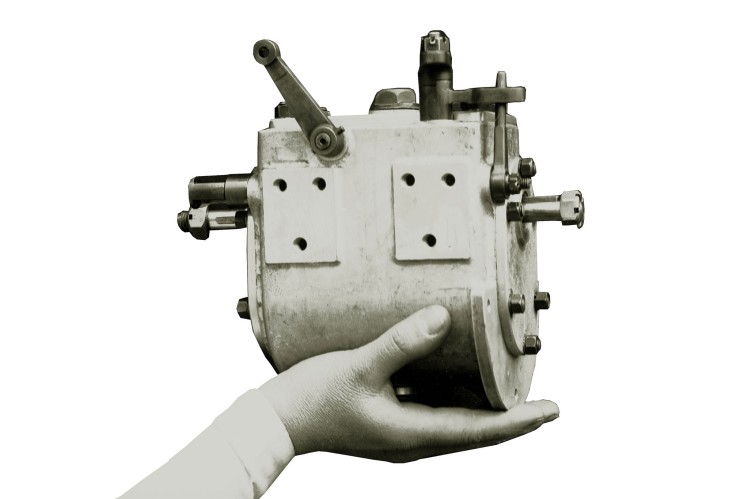

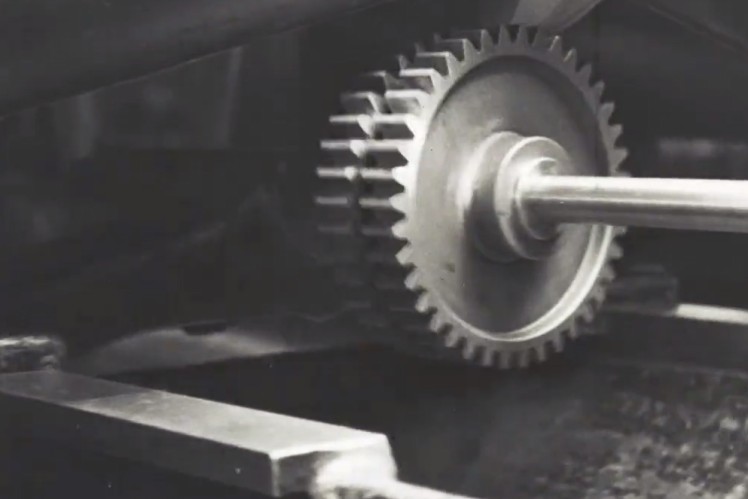

100 Years of Railway Technology

At InnoTrans 2024, ZF will celebrate 100 years of railway technology. In early summer 1924, ZF developed its first drive system for railcars, the "Soden Gearbox TS18.5." Since then, ZF has expanded its position through extensions, acquisitions, and international presence. Today, ZF offers an extensive portfolio and digital solutions for rail vehicle manufacturers and operators worldwide.

2024

Emission-free in XL format

Since 2010, ZF has offered the electric low-floor axle "AxTrax AVE" for city buses, today named AxTrax 2 LF. From 2020, central drives were added. In 2024, ZF combined its powertrain portfolio into a modular system to electrify various commercial vehicles, from delivery vans to 44-ton trucks, trailers, and city and coach buses.

2024

ZF Foxconn

On April 30, ZF Friedrichshafen AG and the Hon Hai Technology Group established their joint venture in the field of passenger car chassis systems. Hon Hai acquired 50% of ZF Chassis Modules GmbH, creating a 50:50 partnership. The joint venture, named ZF Foxconn Chassis Modules, is a key element in the future strategy of both companies.

2024

New Division C

As part of the "Next Generation Mobility" strategy, ZF is merging the divisions for Car Chassis Technology and Active Safety Technology into the new Chassis Solutions division. This division offers hardware, software, and electronics to control vehicle dynamics and will be a strong partner for ZF customers with over 14 billion euros in revenue.

2023

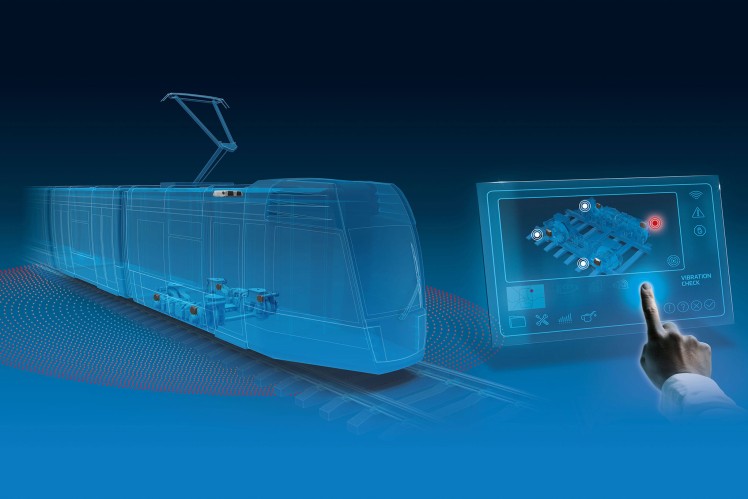

connect@rail

connect@rail combines digital expertise and intelligent connectivity solutions for rail transport. It supports rail operators in monitoring, maintenance planning, and predictive maintenance of their fleets. The system includes the Infrastructure and Driveline Monitoring System and the Smart Identification System for efficient fleet management.

2023

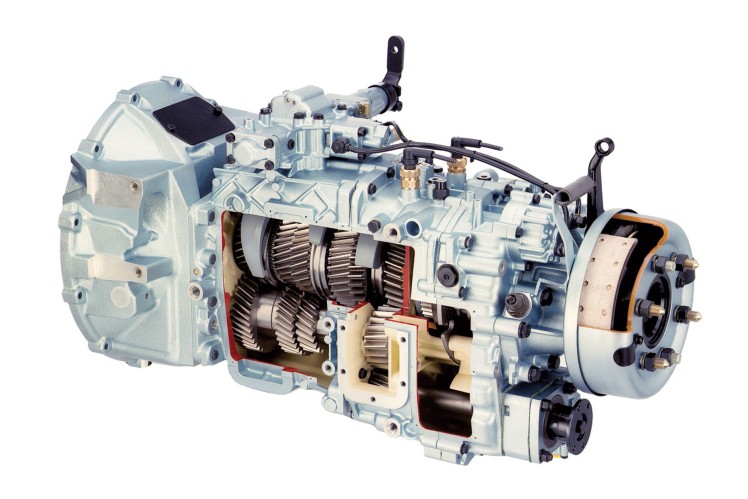

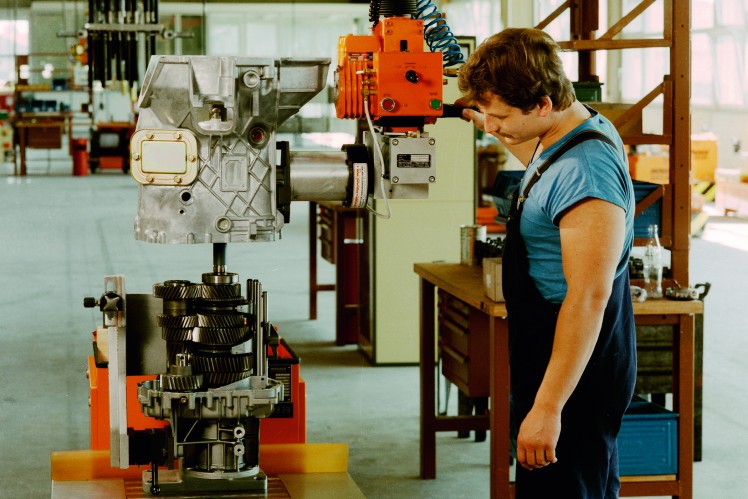

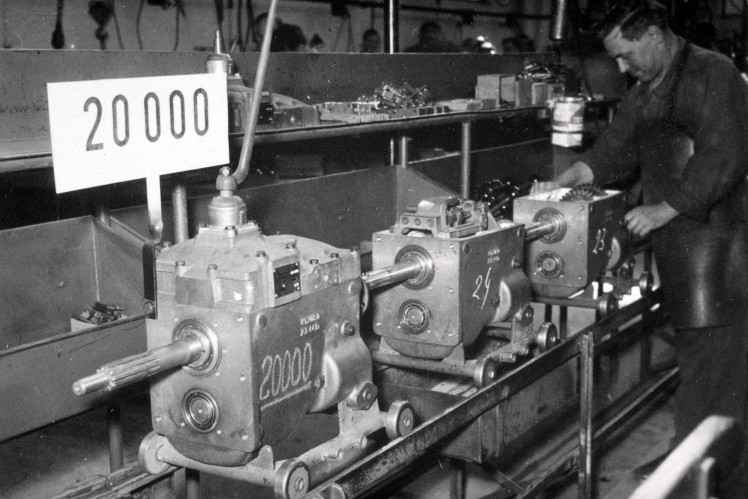

1 Million TraXon

ZF's Commercial Vehicle Solutions (CVS) division reaching the milestone of producing the millionth unit of their TraXon transmission system is a significant achievement. Since its introduction in 2014, TraXon has been renowned for its efficiency, performance, and reliability, contributing to reduced fuel consumption and CO2 emissions.

2023

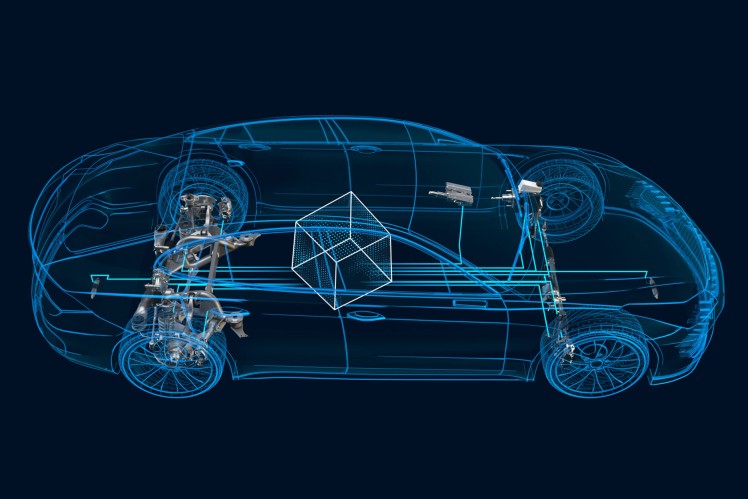

X-By-Wire

At the IAA Mobility starting September 5, 2023, in Munich, the technology company ZF will highlight its range of by-wire technologies. ZF offers one of the most comprehensive portfolios of purely electronically controlled steering, braking, and damping systems for software-defined vehicles.

2023

Board Change

Dr. Holger Klein becomes ZF’s CEO, leading the company into the future.

2022

CeTrax 2

ZF introduces the new electric central drive CeTrax 2, making a significant contribution to next-generation e-mobility for commercial vehicles. As an integrated, modular e-drivetrain for heavy-duty vehicles, the system features two powerful electric motors, a silicon carbide-based inverter, and a multi-speed transmission capable of load shifting.

2022

Networked Rescue Services

ZF Rescue Connect links and digitizes all emergency services in Europe using the latest connectivity solutions. It integrates data from fire departments, rescue services, and other organizations to support emergency management. This system aids in everyday rescue operations and ensures structured, highly efficient responses during disasters.

2022

Acting Now

ZF's commitment to climate, nature, people, and enduring values is encapsulated in the motto "Acting now." This includes production-ready solutions like highly efficient electric motors that almost entirely avoid rare earths, such as the 800-volt motor "EVmore." It also involves a focus on core technologies for software-defined vehicles and new electric-electronic architectures.

2021

cubiX

Software-as-a-Product by ZF: The chassis controller cubiX uses sensor information from the entire vehicle to optimize the control of active systems in the chassis, steering, brakes, and powertrain. The system is being launched in series production with two major OEMs in China. The central software component optimizes driving behavior by processing sensor data.

2021

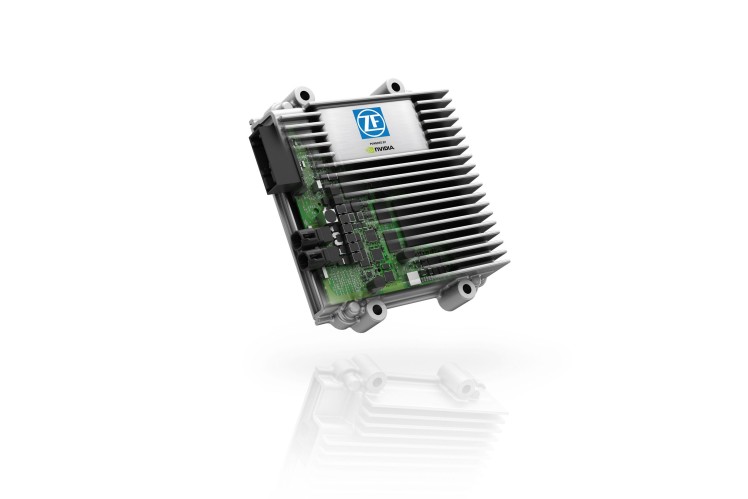

Second Generation

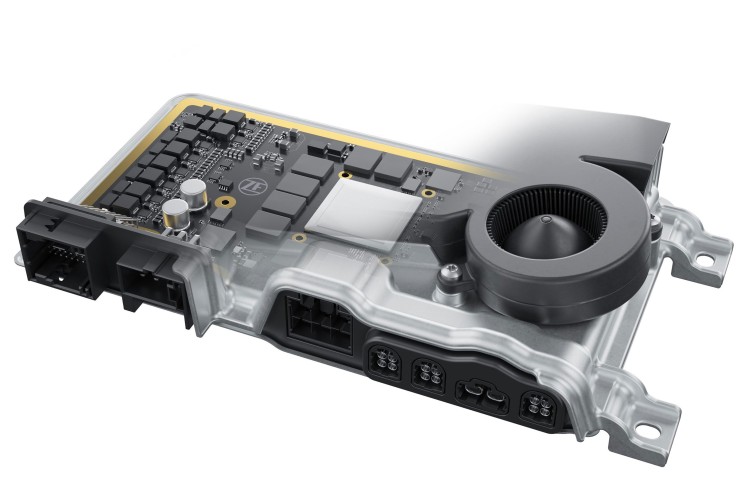

At Auto Shanghai, ZF unveiled the next generation of its supercomputer, ZF ProAI. It is designed to meet the requirements of software-defined vehicles and their new electronic architectures, which are based on domain or zone controllers.

2021

ZF Way Principles

ZF has developed a unique corporate culture called the "ZF Way," which describes collaboration and leadership through five principles: passion, foresight, diversity, empowerment, and responsibility. The "Next Generation Mobility" strategy aims to provide clean, safe, comfortable, and affordable mobility for everyone.

2021

Green Bond From ZF

For the first time, ZF Friedrichshafen AG has issued a green bond. The company is using the proceeds of €500 million to finance its wind power and electric mobility business. ZF is the only technology company that is a key player in both technologies and can thus holistically reduce greenhouse gas emissions – because e-mobility that protects the climate needs sustainably generated electricity.

2020

CeTrax Goes Into Series

The series production of the CeTrax electric central drive for buses highlights ZF's leadership in electrification. CeTrax supports emission-free public transport with its plug-and-drive design, suitable for both new vehicles and retrofitting existing ones.

2020

The WABCO Integration

In May, the acquisition of commercial vehicle brake manufacturer WABCO was completed. As the new Commercial Vehicle Control Systems division, WABCO expands ZF’s portfolio and strengthens its position as a system provider in the commercial vehicle sector. The integration process focuses on driver assistance systems and autonomous functions. Despite the general market weakness, the new division contributes positively to the company’s results.

2020

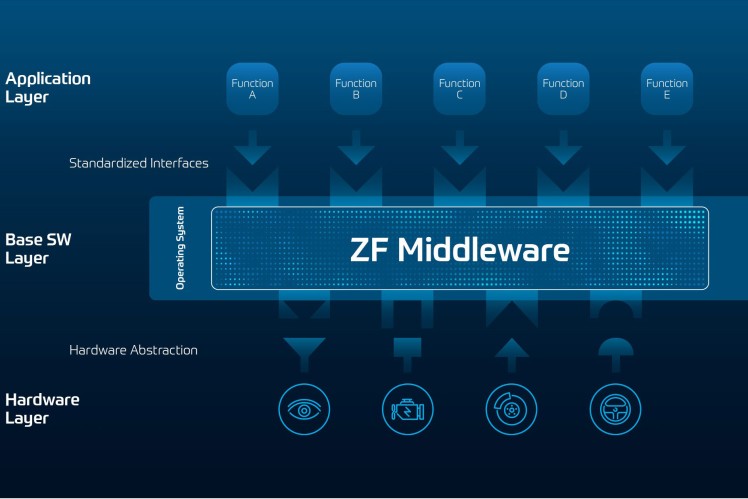

Introduction Middleware

ZF's new middleware platform acts as an intermediary between the operating system of a vehicle computer and its software applications. It accelerates development processes and reduces complexity. From 2024, it is expected to be available in production vehicles, managing the abstraction of hardware from software applications and the communication between these applications.

2020

ZF ProAI

The central computer ZF ProAI RoboThink offers industry-leading computing power and supports NVIDIA's DRIVE Autopilot L2+. The modular and scalable ZF ProAI product family can be configured for various applications. It processes sensor data in real-time, calculates optimal vehicle responses, and continuously learns for everyday automated driving.

2019

Driving Mobility Forward

ZF has been boosting its future mobility efforts through strategic partnerships and acquisitions, including a majority stake in 2getthere B.V. Examples include ZF ProAI, the electric axle drive in the Mercedes-Benz EQC, and the hybridized 8-speed transmission 8HP. A board member in China highlights the market’s importance for ZF.

2018

Board Change

Wolf-Henning Scheider is appointed as ZF’s sixth CEO.

2018

The Company Realigns Itself

To respond more quickly to market changes and technological upheaval, ZF refined its “Next Generation Mobility” strategy in the summer. Organizational structure and processes are being changed to accelerate innovation. Numerous transformation projects aim to achieve the strategy’s goals. Through digitalization and electrification, the entire supply chain is to be made smarter and more environmentally friendly.

2017

"One Company" With a New Look

To signal the integration of TRW, ZF has revamped its corporate design. The premiere was at the IAA in September. Developments such as digitalization and autonomous driving are transforming the company. The new brand claim “see. think. act.” replaces “Motion and Mobility.” The goal is “Vision Zero”: No accidents and no emissions through intelligent vehicles and machines.

2016

New E-Mobility Division

The electrification of drivetrains is key to the future of mobility, and ZF plays a leading role. Since 2008, ZF has operated a production facility for passenger car hybrid modules in Schweinfurt, continuously expanding its portfolio by offering solutions for electric drives and power electronics. In 2016, ZF consolidated its expertise into the E-Mobility Division, which coordinates all activities worldwide.

2015

A Historic Milestone

By integrating TRW as the new ZF Division “Active & Passive Safety Technology,” two market leaders unite under “THE POWER OF2.” ZF contributes driveline, chassis, e-mobility, and electronics expertise, while TRW adds safety, steering, braking, and driver assistance systems. This enables ZF to offer solutions for autonomous mobility, increased safety, and higher efficiency.

2015

100 Years of ZF

Under the motto “One global ZF,” the company celebrated its 100th anniversary in 2015. The focus was on global employee exchange. Selected employees traveled to ZF locations worldwide, connecting with colleagues. Participants in activities like “My Photo with the 100” won additional trips. Family days provided another opportunity for exchange. A special intranet enabled virtual dialogue.

2014

ZF Innovation Truck

The IAA star of 2014 from ZF impresses with over 25 meters in length, 2.5 meters in width, and up to 40 tons in weight. However, its true innovation is revealed during maneuvering: The truck can be remotely controlled via tablet and moved purely electrically, without anyone at the wheel or using the diesel engine. This is achieved thanks to advanced ZF technology components networked into a maneuvering assistant.

2013

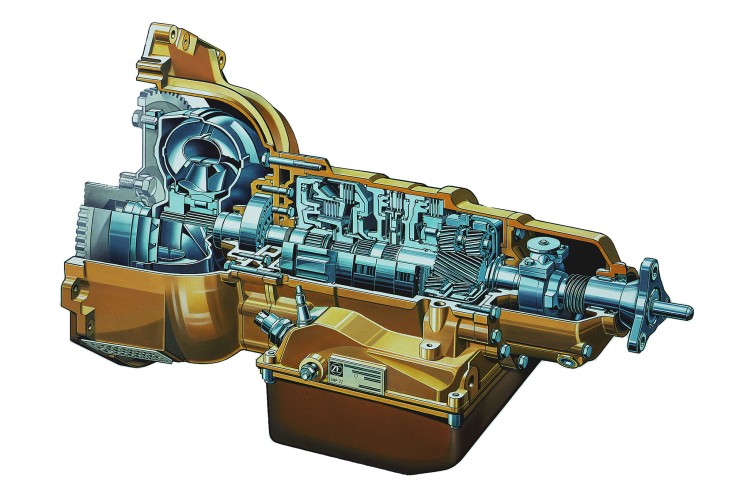

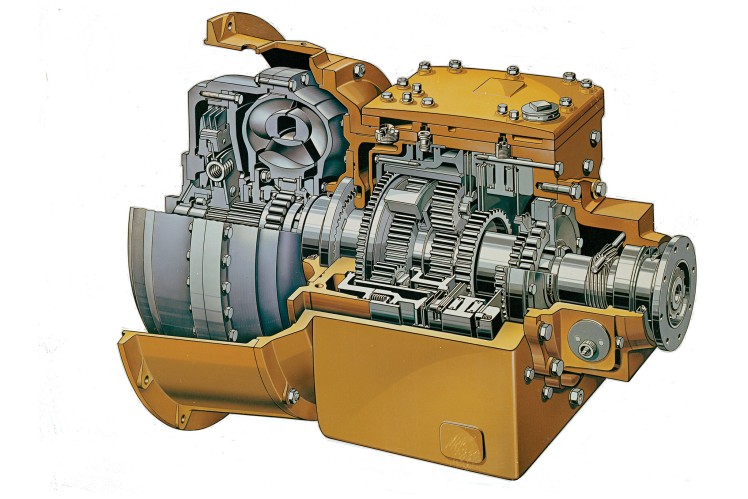

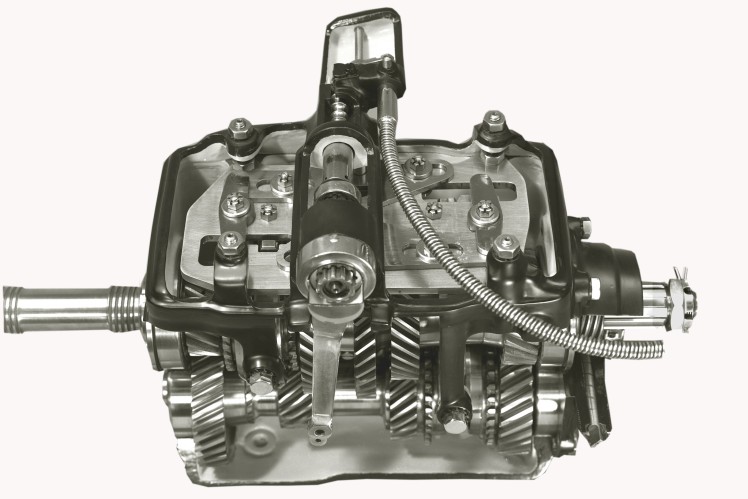

9HP Volume Production

After the 2007-2009 financial crisis, demand for smaller, efficient vehicles rose. In 2009, ZF engineers developed the world’s first 9-speed automatic transmission (9HP) for transverse front installation, ideal for compact vehicles. ZF Electronics’ control system was used for the first time. Introduced in 2011, production began in the USA in 2013, launching in Chrysler and Land Rover models.

2012

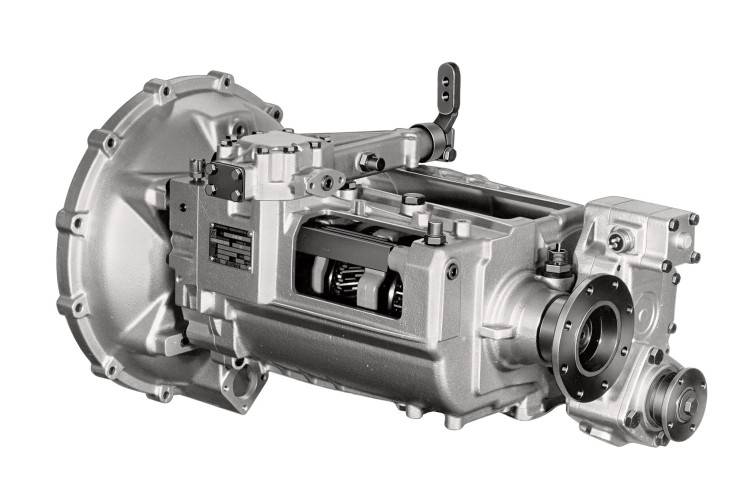

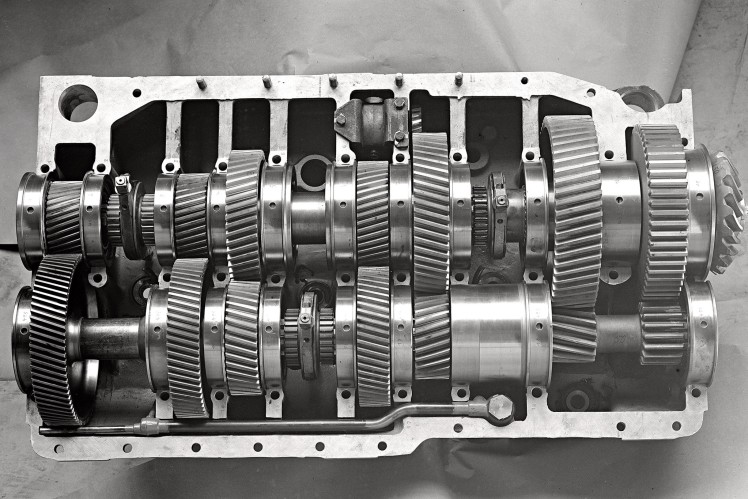

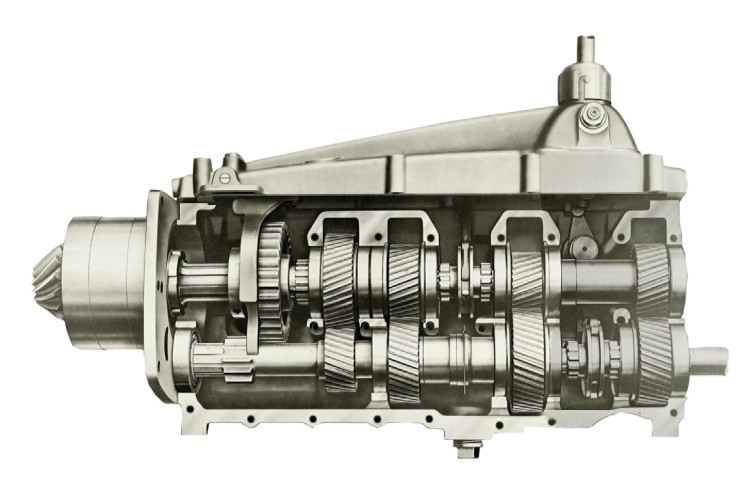

The 7-Speed Manual Gearbox

After the production of the ZF dual-clutch transmission 7DT began in 2008, ZF developed the world’s first 7-speed manual transmission by 2012. The technical basis of the 7DT posed a challenge, as the gears were not in the usual order. ZF developed a mechanism that converts the movement of the gear lever to engage the correct gear. This development, called “MEKOSA,” was patented.

2012

Worldwide Investments

While German locations unified through “Go4ZF!,” ZF expanded abroad. In 2012, construction began on a passenger car axle plant in Beijing, starting production in 2013. ZF intensified cooperation with LiuGong, establishing a joint venture for axle production in Liuzhou. In the USA, ZF expanded with new plants and production lines, including a factory for 8- and 9-speed transmissions in Gray Court.

2012

Board Change

Dr. Stefan Sommer takes over as CEO, succeeding H.-G. Härter.

2011

Wind Turbine Gearboxes

In 2010, ZF established a wind turbine gearbox plant in Gainesville (USA). In 2011, ZF acquired Hansen Transmissions, becoming the number 3 in the market. In 2014, ZF introduced the ‘Atlas 1’ gearbox and opened service centers in Dortmund and Vernon Hills, ready to shape the future of energy supply.

2011

Moving Toward the 9HP

The high demand for 8HP transmissions led to an expansion of production capacity in Saarbrücken in 2010. Development chief Michael Paul emphasized the importance of efficient technology for small, affordable models. ZF engineers developed the world’s first 9-speed automatic transmission (9HP) for transverse front installation, ideal for compact vehicles. It was introduced in 2011, and production began in Gray Court, USA, in 2013.

2010

Restructuring With go4ZF!

The tension between regional identities and global strategy has always shaped the company. ZF committed to “unity in diversity” and granted autonomy to its major plants. However, the decentralized structure led to difficulties. The reorganization into four divisions in 2010 under “Go4ZF!” aimed to create clear competence distribution. In 2011, almost all German ZF companies were unified under the name ZF Friedrichshafen AG.

2009

Engineers of Tomorrow

In 2009, the association Wissenswerkstatt opened in Friedrichshafen to spark an early interest in technology among children. A 450 square meter learning workshop attracted 4,000 young visitors annually. ZF supported the initiative with 2 million euros. The successful concept was expanded to other locations in Germany. In 2015, the association moved into a ‘glass workshop’ on the new ZF premises.

2009

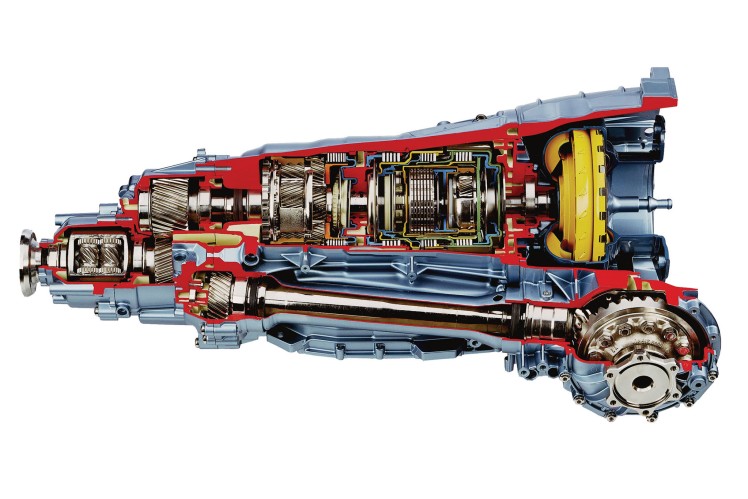

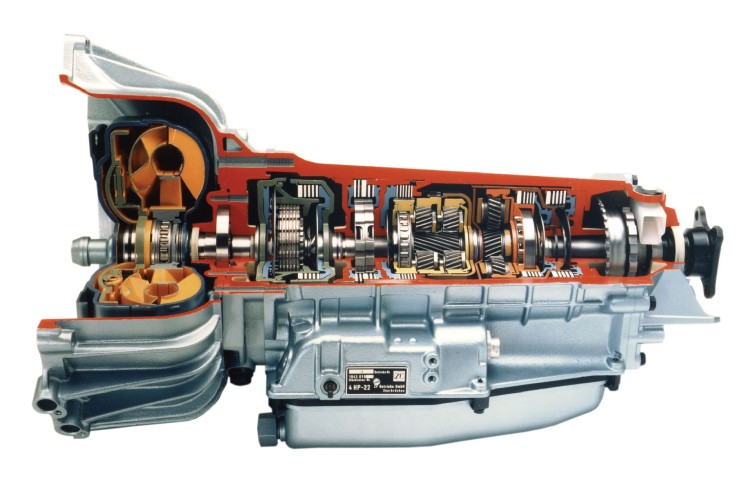

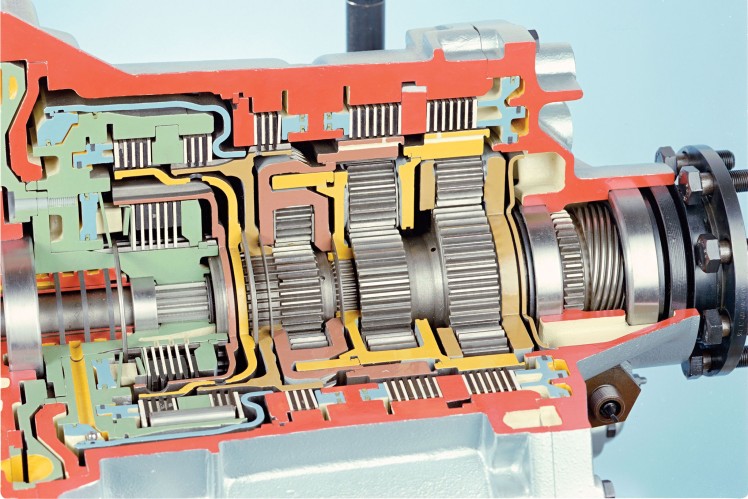

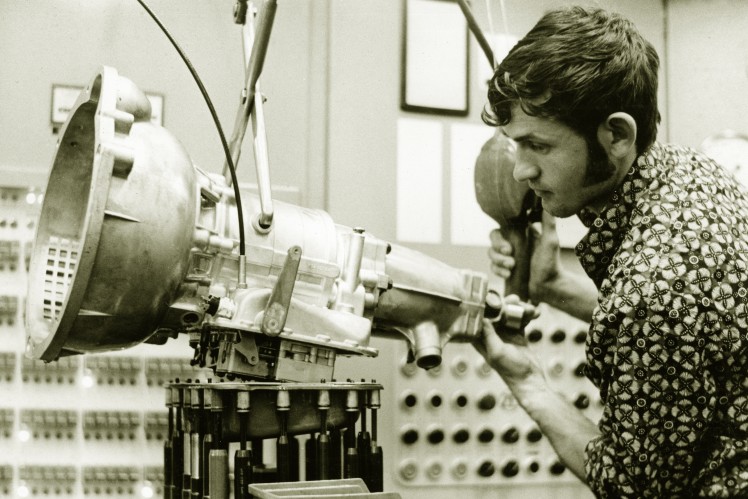

8HP Market Introduction

In 2007, ZF introduced the 8-speed automatic transmission (8HP), achieving around six percent fuel savings. Despite the 2008 financial crisis, demand remained high, and series production began in 2009. The 8HP, developed across multiple locations and including a hybrid variant, became one of ZF’s most successful products, with about 7.5 million units produced by 2014.

2008

Hybrid Drive Technology

To establish itself in the field of hybrid drives, ZF formed a strategic alliance with Continental in 2005. In 2006, Volkswagen commissioned this alliance to build a hybrid drive module. A prototype was presented in the VW Golf V in 2007, with series production starting in the VW Touareg in 2010. In 2008, ZF introduced its own hybrid technology in the Mercedes S 400 Hybrid. ZF believed in the coexistence of various drive types.

2007

ZF Engineering Pilsen

In order to extend its international development network, ZF founded ZF Engineering s.r.o. in Pilsen (Czech Republic) in July 2007, thereby simultaneously acquiring the Czech company Value Engineering Services. The aim was to actively participate in the continuous growth of development sectors abroad. The new company with initially around 150 employees was to focus primarily on software and mechatronics.

2007

The Fourth CEO

Hans-Georg Härter becomes the fourth CEO in ZF’s history.

2006

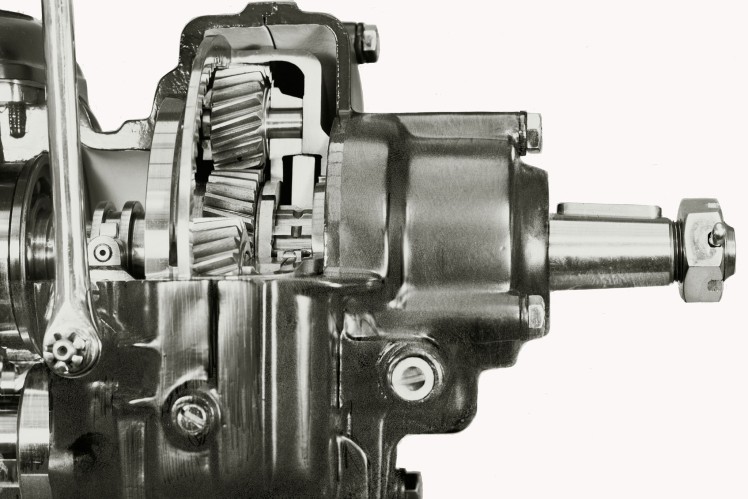

New Generation of 6HP

In 2006, ZF revised the 6HP automatic transmission after four years of development. The mechanical design remained unchanged, but the electrohydraulic control and software were improved. The goal was to optimize fuel consumption, shift dynamics, and shift precision. The new 6HP saved three percent more fuel, and six percent for diesel engines. New damping technology and adaptations increased shift speed and comfort.

2006

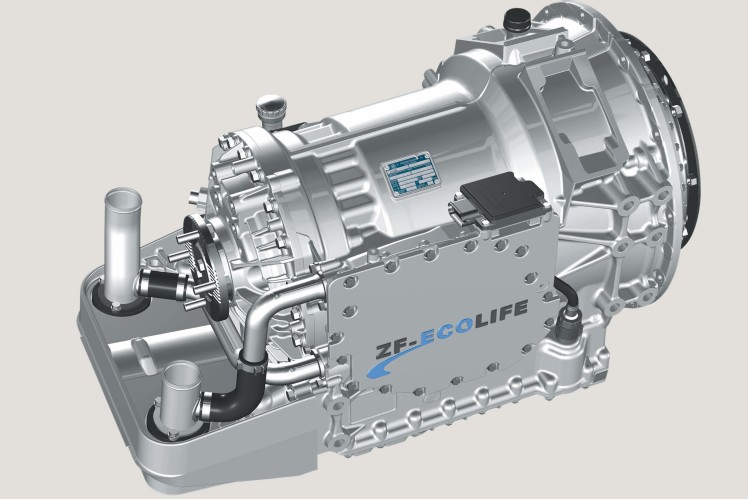

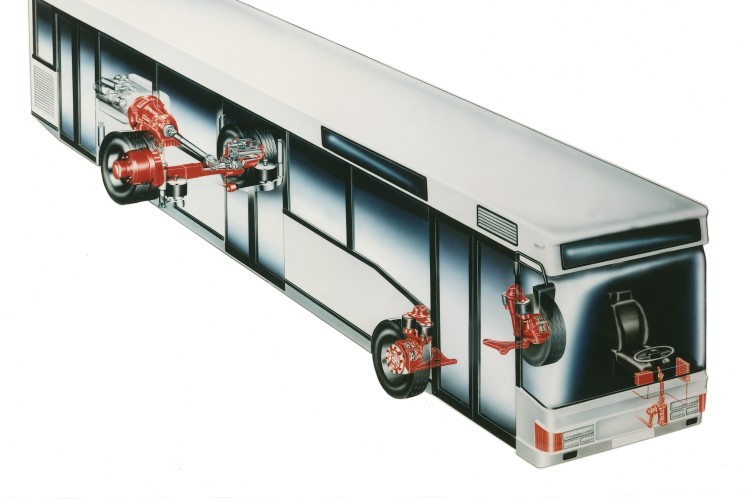

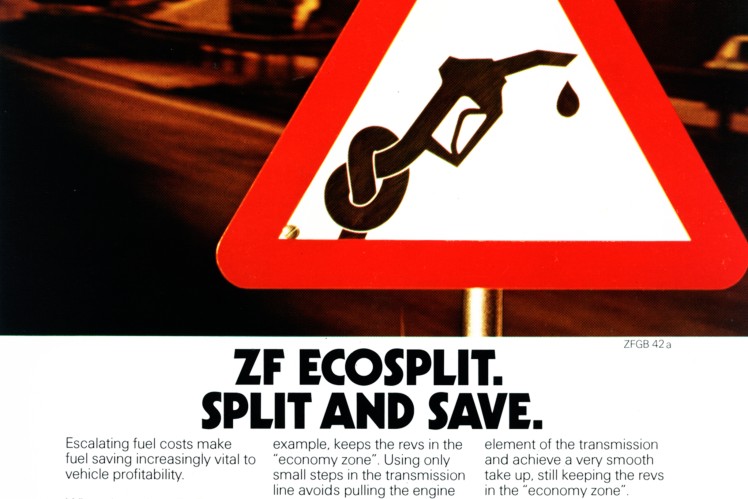

EcoLife

At the 2006 IAA, ZF presented the new EcoLife bus transmission, an evolution of the successful Ecosplit transmission. “Life” indicates higher durability and temperature resistance. The 6-speed automatic transmission features a dual cooling system, which allows for lower oil temperatures and up to 40 percent higher retarder braking performance. Further improvements reduced fuel consumption by 5 percent.

2005

Alternative Drives

In 2005, ZF’s revenue exceeded ten billion euros for the first time, more than double the amount in 1995. The automotive industry remained the most important sector. At the beginning of the millennium, growth shifted to Asia, particularly China and India. Intelligent, efficient vehicles became more important. ZF benefited from its experience with alternative drives, such as the EE-Drive introduced in 1994.

2004

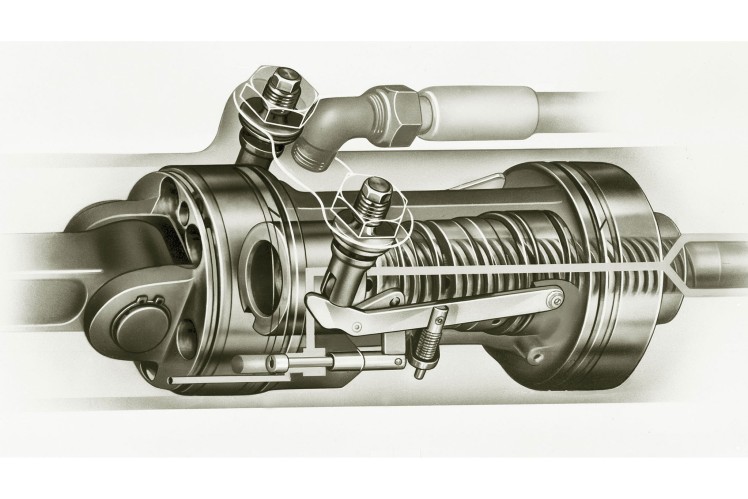

Continuous Damping Control

Before merging with ZF, Sachs developed the Continuous Damping Control (CDC). An electrically adjustable proportional valve regulated the oil volume and thus the damping at each wheel. Sensors provided the necessary data. The first series application was in sporty Opel models. From 2006, CDC was also offered for commercial vehicles.

2004

ZF Helps – Worldwide

Founded in April 2005 after the 2004 tsunami, “ZF hilft” shows ZF employees’ social commitment. Initially, 477,000 euros were raised, which ZF increased to one million euros. Projects under “help for self-help” followed. In 2015, the largest project, “100 Years – 100 Schools,” was launched to fund 100 educational institutions in the world’s poorest regions.

5/13/2003

New Ownership Structure

In 2003, ZF changed its ownership structure: On May 13, ZF took over 100 percent of Lemförder Metallwaren AG, while the Dr. Jürgen Ulderup Foundation exchanged its 24.4 percent stake for 6.2 percent of the entire company. The remaining 93.8 percent stayed with the Zeppelin Foundation. This created clearer structures in the growth segment of passenger car chassis technology and facilitated cross-divisional developments.

2002

Great Synergy Potential

The 2001 annual report stated that ZF and Sachs fit together “like a nut and bolt.” Sachs’ clutches, torque converters, and shock absorbers corresponded with ZF’s power units, transmissions, steering systems, axle systems, and chassis components. However, the acquisition of Sachs could only fully realize its technological potential through coordinated product developments.

2001

Sachs Becomes Part of ZF

In February 2000, the takeover of the Mannesmann Group by Vodafone was finalized. The industrial sector of Mannesmann, including the future ZF subsidiary Sachs, was incorporated into Atecs Mannesmann AG. After the purchase by Vodafone, Atecs was sold to a consortium led by Siemens and Bosch. ZF eventually took over the entire Mannesmann Sachs company in October 2001 after more than a year of preparation.

2001

Quo Vadis Sachs?

When ZF took over Sachs in 2001, Sachs employed around 18,000 people, increasing ZF’s workforce by 50%. The renaming to ZF Sachs AG happened immediately. The cultural integration was the biggest challenge. The exchange between the companies went well. ZF adopted a federal approach, and the SACHS brand was retained. The two companies gradually merged.

2001

Board Change

After eleven years, Dr. Siegfried Goll succeeds Dr. Klaus Bleyer as CEO.

2000

ZF is a System Supplier

The new BMW X5 is equipped with the ZF 5 HP 24 automatic transmission, ZF Servotronic, and both front and rear axles from ZF. The ZF-AS Tronic automatic transmission system, the independent wheel suspension concept, and the new RL 75 E and A 132 axle systems become available for touring buses.

1999

Lighter. More Efficient. Quieter.

ZF establishes ZF-Achsgetriebe GmbH and builds a new plant in Thyrnau. ZF Hurth Bahntechnik is rebranded as ZF Bahntechnik GmbH, with operations in Passau and Gotha. At the IAA Hannover, ZF presents the 6 HP 26 six-speed automatic transmission, which is lighter, more efficient, and quieter than its predecessors.

1998

Foundation ZF Bouthéon S.A.

ZF acquires Renault V.I.'s transmission production, forming ZF Bouthéon S.A. for Ecomid truck transmissions. The Ecomat 2 series evolves with ECD engines for smoother shifts and a refined ZF-Intarder. The new 6 S 300 transmission boosts ZF’s van and pickup drivetrain leadership, while the compact Servotronic 2 steering system gains popularity in mid-size cars.

1998

ZF Becomes Systems Supplier

In 1998, ZF surpassed 10 billion Deutsche Marks in revenue for the first time. This was due to internationalization and a strategic shift by automakers who wanted to source complete systems from partners. ZF received the contract for axle production for the Mercedes M-Class and built a facility in Tuscaloosa, Alabama. As early as 1994, ZF had established plants in Spartanburg and Duncan, South Carolina, for the BMW Z3 Roadster.

1997

New Euro Standards Regulations

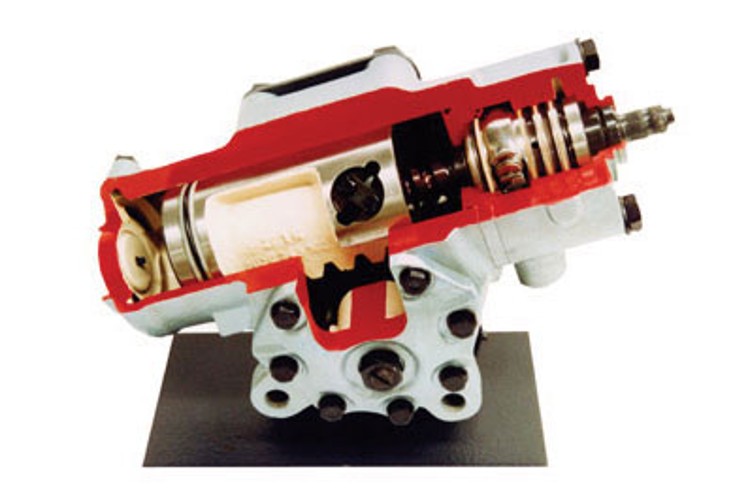

ZF launches production of the S 6-1600 bus transmission for city and touring buses, designed to meet Euro II and Euro III emission standards. The Servocom-Tronic ball-and-nut power steering system for commercial vehicles enters the market, offering a level of ease similar to the Servotronic power steering system used in passenger cars.

1997

The US Business Grows Up

Despite growth in China, the USA remained the most important foreign market for German automakers. ZF had several locations but low value creation. Elizabeth Umberson, the first female plant manager at ZF in 1999, recalls: “In 1994, ZF was almost unknown in the USA.” ZF regionalized production, leading to annual savings. Revenue increased by 62 percent between 1994 and 1999, while the workforce grew by 6.4 percent.

1997

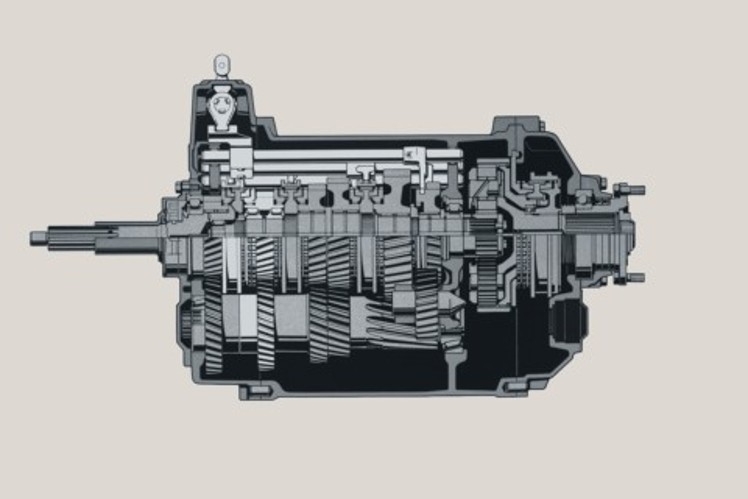

AS Tronic

In the 1990s, ZF developed the AS Tronic, the first fully automated truck transmission, facing significant mechatronics challenges. Efficiency was key, with electronic control selecting the optimal gear. Series production began in 1997. By 2007, 250,000 units were delivered, and by 2011, the half-million mark was surpassed.

1996

Production start of the 4 HP 20 automatic transmission

ZF Saarbrücken begins production of the 4 HP 20 automatic transmission for transversely mounted front-wheel-drive engines, installed in models such as the Mercedes Vito and Peugeot 605. Series production of the FS 108 main transmission for the Eurocopter EC 135 starts. ZF Schwäbisch Gmünd delivers its 50-millionth steering system since 1945.

1995

Quality Redefined

By the end of 1995, group work was almost universally implemented at ZF. Simultaneously, the company reduced waste and friction losses with TQM. In 1992, Hubertus Christ described the new corporate quality as comprehensive. TQM revitalized the company suggestion system, which was improved through decentralization and mentorships between idea submitters and managers.

1995

Acquisition of Hurth

Through the acquisition of the rail technology, material handling, and marine divisions of the Hurth Group, including plants in Gotha (Germany) and Arco (Northern Italy), ZF expands its product portfolio. Series production begins for the first five-speed automatic transmission for front-wheel drive, the 5 HP 19 FL, along with its all-wheel-drive version FLA in longitudinal configuration.

1995

Joint Ventures in China

ZF establishes two joint ventures in China: Liuzhou ZF Machinery with Guangxi Liugong and Shanghai Lemförder Automotive. Construction of a plant for tie rods and ball joints begins in 1996. Additionally, the steering technology division opens a new production facility for ZF Steering Gear in Pune, India.

1995

Expansion in Europe

In 1994, ZF acquired the remaining 50% of Henschel Flugzeug-Werke GmbH. In 1995, ZF purchased HURTH Marine Gear S.p.A. and acquired the rail technology and material handling sectors. A competence center for forklift systems was established in Gotha. ZF relocated parts of its production to Hungary, buying a transmission plant in Eger in 1995. In 1997, a joint venture with Renault in Bouthéon was formed.

1994

Foundation ZF Luftfahrttechnik GmbH

ZF establishes ZF Luftfahrttechnik GmbH through the merger of HFW Kassel with its own aviation-related activities. The ZF-EE Drive electric propulsion system for city buses is introduced, reducing entry height, emissions, and fuel consumption. Additionally, ZF develops new automated transmission systems under the Autoshift family, including ZF-AS Tronic for heavy commercial vehicles, which enters series production in 1997.

1994

Axle Assembly in the USA

Despite growth in China, the USA remained the most important foreign market for German automakers in the late 1990s. Starting in 1994, ZF built plants in Spartanburg and Duncan (South Carolina) for axle production for the BMW Z3 Roadster, with series production beginning in 1996. In Tuscaloosa (Alabama), a plant for axle production for the Mercedes M-Class was established. ZF became a system supplier.

1993

ZF in Airbus

For the Airbus A340 and the twin-engine A330, ZF supplies the transmission for the auxiliary power unit and the flap actuation system.

1993

Pioneers in China

China was an early focus for ZF, emphasized Siegfried Goll, who led the Passenger Car Driveline Technology division since 1993. Business relationships began in the 1980s. In 1993, a joint venture with Beijing North Vehicle Works was established, followed by ZF Shanghai Steering Co. Ltd. in 1994. In 1995, ZF created two new joint ventures, and in 1998, the wholly-owned subsidiary ZF Drivetech Co. Ltd. in Suzhou.

1992

ZF-Intarder

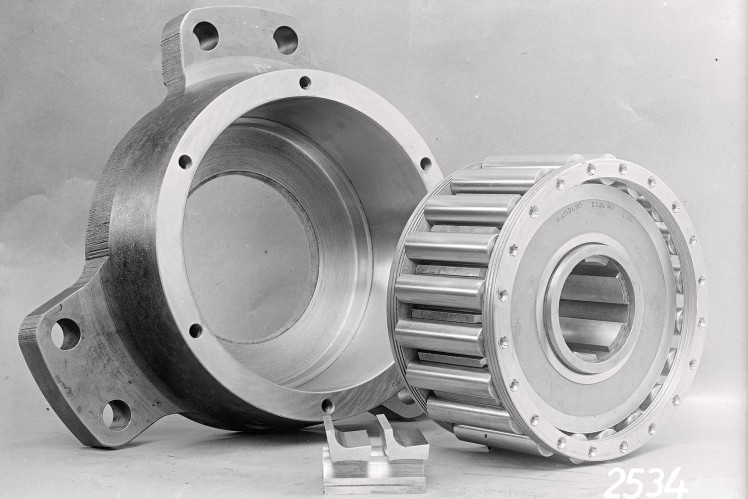

ZF Passau introduces the new AP-R-700 ZF-Multisteer and ZF-Multitrac series. This seven-axle series is designed for wheel loaders, backhoe loaders, multi-purpose vehicles, telehandlers, and municipal vehicles. ZF presents the newly developed, integrated, wear-free ZF-Intarder transmission brake, which successfully enters the market alongside the third-generation ZF-Ecosplit transmission.

1992

A New Name

As of the beginning of the year, ZF operates under its new name: ZF Friedrichshafen AG, reflecting the expansion of its product range and business activities in non-European markets. Early in the year, series production begins for the five-speed automatic transmission 5 HP 30, designed for engine torque up to 560 Nm. Its gear shifts are largely controlled by electronic regulation processes.

1991

Founding of ZF Service GmbH

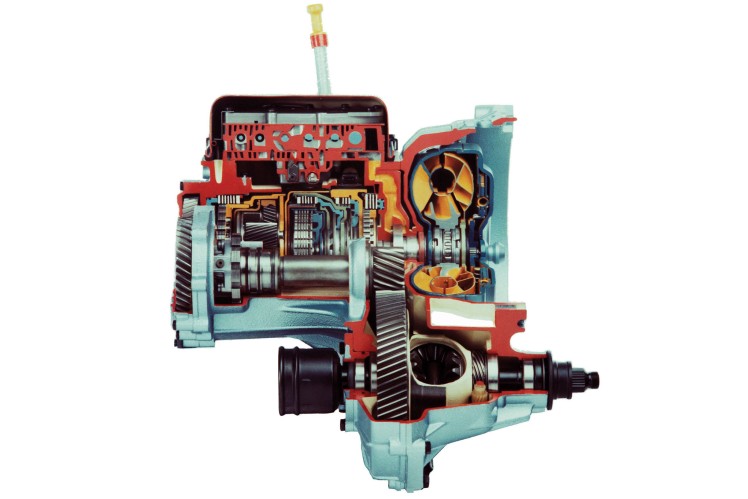

ZF establishes ZF Service GmbH. Series production begins for the 4 HP 18 FLE and 4 HP 18 FLA transmissions for front-wheel-drive vehicles with longitudinal engines, including the Porsche 968. Production also starts for the Nkw-Ecosplit 16 S 151 transmission with an integrated clutch and gearbox.

3/1991

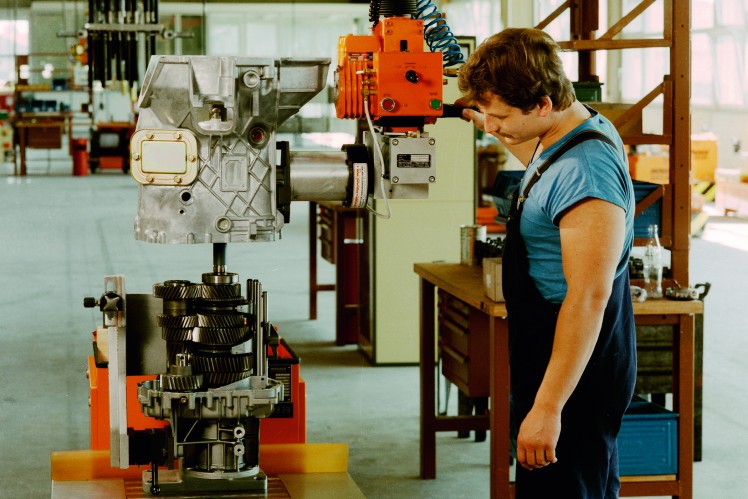

Entry Into Brandenburg

Although ZF did not plan major investments in the new federal states, exploratory talks took place before reunification. A collaboration with the Brandenburg transmission plant emerged. The acquisition was completed in March 1991, with the handover in July 1991. The plant needed renovation, and the production of the S5-24 transmission was relocated from Schwäbisch Gmünd to Brandenburg.

1990

ZF Art Foundation

In 1990, ZF founded the Art Foundation to support culture independently of business performance. The goal was to consolidate requests from the Lake Constance region and enhance funding activities. From the mid-1990s, the foundation focused on institutions and event formats. Since 1999, it has supported the International Piano Festival of Young Masters in Lindau and has awarded the ZF Music Prize since 2001.

1990

Board Change

Dr. Klaus Bleyer is appointed as the new CEO. ZF introduces its first five-speed automatic transmission for passenger cars, the 5 HP 18, which impresses experts with its high efficiency and fuel consumption reduction.

1989

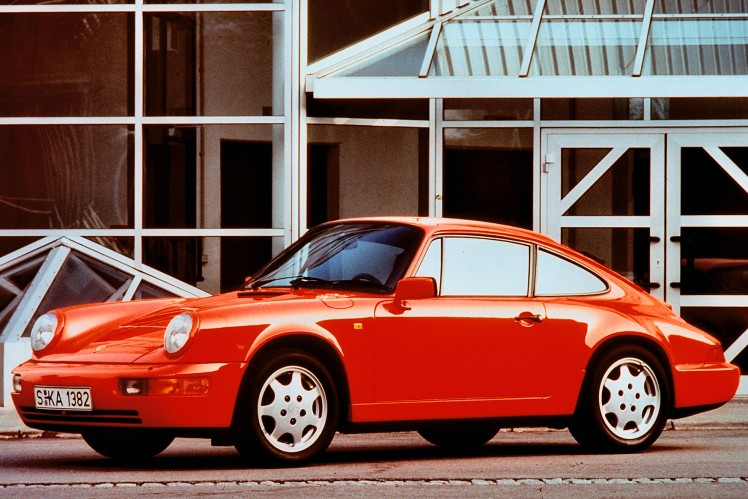

Shifting with Tiptronic

The Porsche 911 Carrera 2 is available with the 4 HP 22 HL and Tiptronic transmission, allowing both manual and automatic shifting without interrupting power flow. The new BMW 850i generates significant interest, featuring a ZF ball-and-nut power steering system, optionally equipped with Servotronic and an automatic transmission.

1989

Redistribution

The Zeppelin Foundation increases its ZF stake to 92.5%, while the Zeppelin heirs hold 7.5%. Revenue surpasses six billion marks for the first time, and the workforce grows to 34,500 employees. ZF acquires an additional 25% of Lemförder Metallwaren AG, increasing its ownership to 76%.

1988

New Standards

The 4 HP 24 A automatic transmission for the Audi V8 sets new benchmarks. The new GM Corvette is equipped with the S 6-40 six-speed transmission, featuring short, precise shifting. The Ecosplit 2 series optimizes production, while ZF short-travel and dual-cone synchronizers in the 16 S 150 and 16 S 220 facilitate shifting in heavy trucks. The Danish high-speed train IC 3 operates with a ZF-Ecomat transmission.

1987

More 4-speed automatics

ZF establishes its own sales and service company, ZF Australia, in Sydney. Series production begins for the electronically controlled 4 HP 24 automatic transmission for the 12-cylinder BMW, as well as the 4 HP 18 FL automatic transmission for front-wheel drive vehicles with a longitudinally mounted engine, supplied to Chrysler in the USA.

1986

Portfolio expansion

ZF expands in the U.S. with two new locations: ZF Transmissions Inc. in Gainesville, Georgia, begins production of the Ecolite S5-42, while ZF Steering Gear in Brewer, Maine, manufactures the FP4 hydraulic pump for Chrysler. In Padua, the product range is extended to include marine transmissions for sport and workboats. In Saarbrücken, ZF produces the 4 HP 18 automatic transmission for Fiat, Lancia, Alfa, Saab, Peugeot, Citroën, and BMW.

1986

Servotronic

In the mid-1980s, microelectronics began to revolutionize the automotive industry. In 1982, ZF introduced the Servotronic, the first speed-dependent power steering system. The steering assistance operated at full power when parking, and decreased at higher speeds, enhancing steering precision. The Servotronic went into series production in the BMW 7 Series in 1986. In 1998, the more compact and cost-effective Servotronic 2 followed. By 2011, twelve million systems had been delivered.

1986

Transatlantic Expansion

In the 1980s, ZF aimed to expand its production internationally. There was great excitement when Ford commissioned ZF in 1986 to build 500,000 5-speed transmissions for pick-ups. A new hall was built in Friedrichshafen within six months. However, the fall of the dollar exchange rate led to losses. In 1986, ZF founded three US companies and increasingly shifted transmission production to Gainesville.

1985

ZF Ecomid

In Friedrichshafen, series production of the ZF-Ecomid transmission range begins with the 9 S 109 and 16 S 109 models. A contract with Ford USA secures the annual delivery of over 100,000 S 5-42 transmissions from the Ecolite family. ZF establishes ZF Steerings in Penang, Malaysia, to manufacture steering systems for the Southeast Asian market.

1984

With Four Courses Ahead

ZF Steering Gear India Ltd. is inaugurated in Pune. Production starts for the 4 HP 14 automatic transmission for compact, front-wheel-drive vehicles, with customers like Citroën and Daewoo. The 4 HP 22 production volume increases significantly. Series production of the more compact and lighter ZF-Servocom truck power steering system begins.

1/2/1984

Acquisition of Lemförder

In the early 1980s, ZF met Jürgen Ulderup, who was considering selling his company, Lemförder Metallwaren AG, founded in 1947. In December 1983, the ZF board proposed acquiring a majority stake. Lemförder’s products ideally complemented ZF’s portfolio. The acquisition agreement was signed on December 28, 1983, and took effect on January 2, 1984. ZF recorded an immediate increase of around 22 percent.

1983

Low-Floor Technology

In the early 1980s, the impetus came from France to make public transport more accessible for people with disabilities. ZF developed an inverted portal axle that lowered the vehicle floor. The patent was filed in 1980, and series production began in 1983 with the AV130 model. The first customer was “Cars & Bus Le Mans,” later Renault. In 1985, the low-floor axle went into series production at Kässbohrer.

1982

New Management Structure

In June 1982, Friedrich Baur became the CEO of ZF. Under his leadership, ZF began to focus on North America and Asia. Initially, the internal reorganization of the company, which had grown to over 22,000 employees, was the main focus. The leadership structures were adjusted to speed up decision-making processes. The operational business was divided into two regional areas.

1981

Subsidiary in India

In 1981, ZF, together with Bajaj Tempo Ltd., founded the subsidiary ZF Steering Gear (India) Pvt. Ltd. in Poona. Bajaj Tempo had been using the ZF 4 DS 10 transmission since 1965. The new company was to manufacture steering systems for the Indian market. Series production began in December 1983, and the plant was inaugurated in early 1984. Premier Automobiles in Bombay became another customer in 1984.

5/7/1980

Foundation in Japan

On May 7, 1980, ZF founded the sales company ZF Japan Co. Ltd. in Tokyo. Japan was an important vehicle market, and ZF wanted to be present there. On July 1, ZF of South Africa in Johannesburg begins operations as a sales and service company.

1980

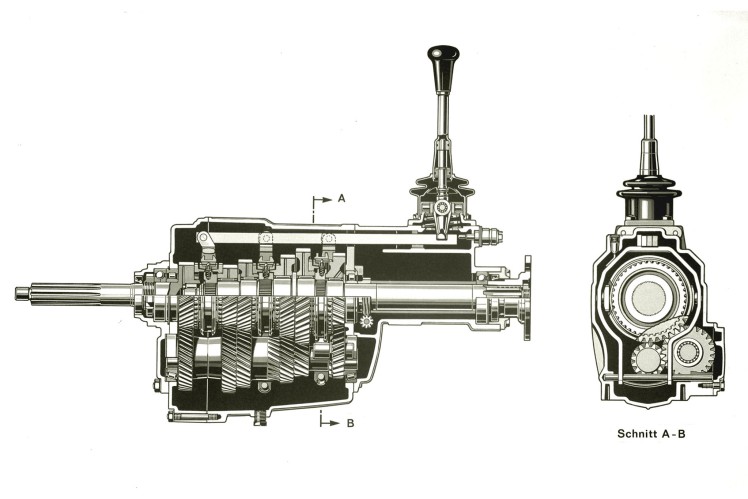

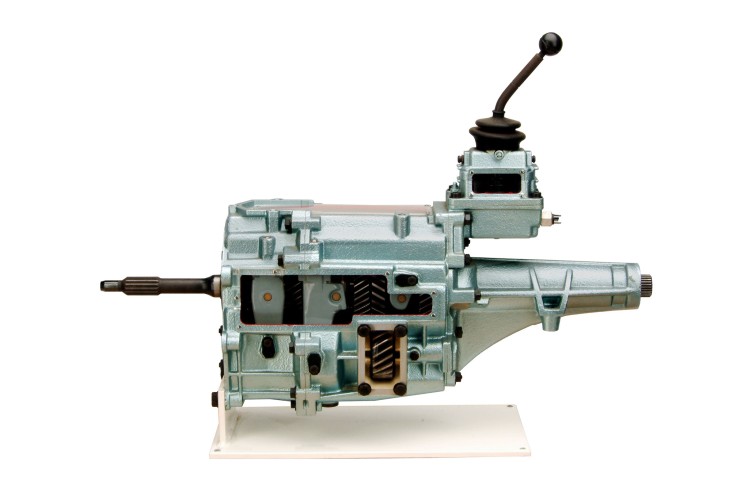

Ecosplit in Series

In 1980, the durable Ecosplit transmission for heavy trucks went into series production. ZF optimized maintainability through unconventional approaches, as engineer Heinz Hässle explained in 1980: “It was meant to be a simple, uncomplicated transmission.” Since its presentation in 1979, the transmission has been part of the program. In 2008, the two-millionth unit was delivered. Outstanding reliability was the key to its success.

1979

ZF-Ecolite

ZF launches series production of the ZF-Ecolite transmission range with five and six gears in Friedrichshafen. The S6-36 is the first transmission of this series.

1979

ZF of North America

On March 8, 1979, ZF of North America, Inc. was founded in Northbrook near Chicago. Business operations began on May 1, 1979, with 11 employees. ZF aimed to establish itself as an original equipment manufacturer in the US market and improve customer service in North America. In the early 1980s, ZF received an order from Ford to build 500,000 5-speed transmissions. A new production hall in Friedrichshafen was completed in record time in 1986.

1978

New Base in Argentina

Fábrica Argentina de Engranajes, Buenos Aires, becomes ZF's latest overseas base. This investment aims to open up the Argentine market for transmissions, steering systems, and pumps. The FS 110 helicopter transmission for the more powerful version of the BO 105 by MBB enters series production in Friedrichshafen. In Schwäbisch Gmünd, production of the four-speed synchronized transmission 4 DS 18 for transporters and minibuses begins.

1977

ZF-Ecomat

ZF begins series production of the HP 500, an automatic transmission for buses and commercial vehicles. Continuously developed under the name ZF-Ecomat, it becomes a key driver of the company's success. Additionally, the APL 1552 tractor steering axle enters series production - designed with a planetary gear system, it allows a steering angle of up to 40 degrees.

1976

Marine Gears Expand

At the Hannover Messe, ZF presents the BW 2010 transmission for high-speed ships. In addition to the BW 6, the more compact BW 7 is produced. The BW 800, BW 900, and BW 1200 models are used worldwide in naval vessels, hydrofoil boats, yachts, and sea rescue cruisers. The record-breaking car Dieselstar by Fritz Busch, equipped with the ZF 5 DS 25/1 transmission, accelerates to 100 km/h in 5.6 seconds and reaches a top speed of 256 km/h.

1975

Business is Booming

The number of ZF transmissions produced exceeds 1.5 million units. In Schwäbisch Gmünd, 500,000 limited-slip differentials have been manufactured. The WG 120 reversing transmission with a planetary gear design enters series production in Passau. Gears 3 to 6 can be shifted under load.

1974

Large Order from Peugeot

ZF Saarbrücken signs a seven-year contract with Peugeot for 400,000 automatic transmissions of the 3 HP 22 type - a significant milestone for the plant. BMW is also among the customers. ZF-Transmatic, a combination of a torque converter clutch with automatic lock-up and a ZF synchronized transmission, enables smooth starting under difficult conditions.

1973

New Development Center

In August 1971, construction began on a new development and testing center in Friedrichshafen to consolidate the various testing departments and test stands. The inauguration took place in November 1973. At the same time, ZF adopted a team-oriented model for the design of the Ecosplit transmission, which included customer service and quality assurance.

1973

Oil Price and Ecosplit

The oil crisis of 1973 led to rising fuel prices and gasoline hoarding. The “Energy Security Act” banned the use of motor vehicles on four Sundays, causing a drop in car demand. On the positive side, it spurred the development of fuel-efficient drives. ZF introduced the reliable Ecosplit transmission for trucks, which remains in the program to this day. In 2008, the two-millionth unit was delivered.

1973

ZF Travels the World

In 1972, the export quota reached 35 percent of total sales. Indirectly, the share was higher, as transmissions and steering systems sold domestically also found their way abroad. In Germany, ZF suffered from rising costs. The willingness to internationalize grew: In 1973, ZF acquired 50% of ISA in Spain and in 1979, 49% of FAE in Argentina, marking key steps towards internationalization, especially in South America.

1972

Expansion in Vienna

ZF establishes a subsidiary in Vienna-Inzersdorf in October, named Zahnradfabrik Friedrichshafen GmbH. In Passau, ZF launches a new series of tractor transmissions under the T 3000 designation.

1972

Automatic Transmissions

Shortly before Christmas 1970, ZF delivered the 100,000th 3HP automatic transmission for passenger cars. To expand the business, ZF founded ZF-Borg-Warner GmbH in March 1970 for the production of automatic transmissions in Saarbrücken. Borg Warner exited the joint venture shortly before production began, and in March 1972, ZF took over all shares. The subsidiary was then named ZF Getriebe GmbH.

1971

Reform in Customer Service

A decentralized technical customer service was established: Dr. Ernst Braun wanted to reform the structure by taking over or founding foreign representations. The ZF network grew in Europe, South Africa, and the USA. The goal was to increase profits and set up a warning system for quality defects. Customer service helped to increase sales opportunities. From the 1980s, the scope of tasks expanded and the number of employees increased.

1971

100.000 Automatic Transmissions

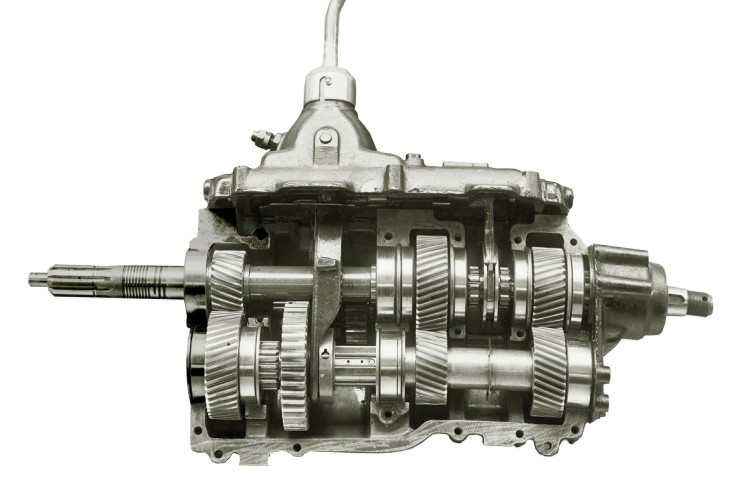

The 150.000th AK 6-80 truck transmission rolls off the production line and the 100.000th passenger car automatic transmission is produced at Friedrichshafen. ZF introduces the 8045 ball-and-nut hydraulic steering system in a compact design for vehicles with steering axle loads up to 7.500 kg. The fully synchronized manual transmission S 5-24/3 for passenger cars, light commercial vehicles, and special-purpose vehicles enters series production.

1970

Plant in Saarbrücken Established

ZF and Borg-Warner establish ZF Borg-Warner GmbH to produce automatic transmissions for the European market, with a new plant in Saarbrücken. ZF's workforce grows to 19,000 employees. At the Hannover Air Show, ZF presents the FS-72 transmission system for the BO 105, the first serially produced helicopter developed in Germany by MBB.

1969

World-Class Relies on ZF

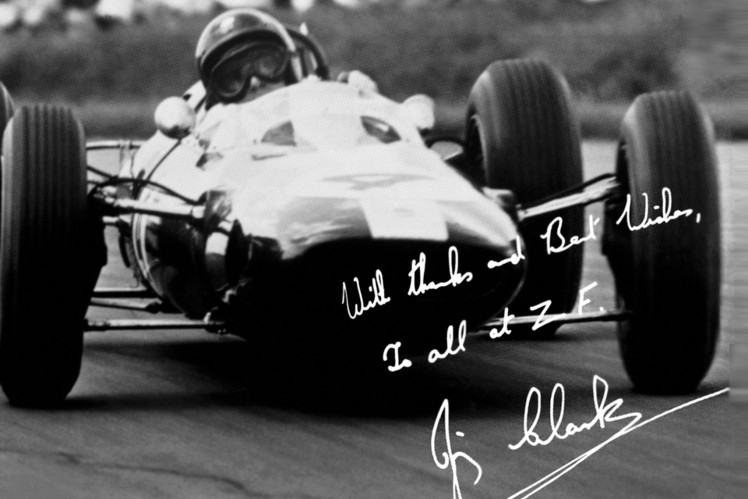

Formula 1 race cars from Cooper and the legendary Ford GT40 use the ZF five-speed transmission 5 DS 25 and 5 DS 25/1, specifically developed for motorsport. Many top engineers and world-class drivers rely on ZF technology. The Mercedes-Benz C 111 prototype is also equipped with the 5 DS 25/1 transmission.

1969

Drives for Aviation

“In 1957, a working group for aviation was formed at ZF, and in 1969, it became an independent aviation department. At the same time, the high-performance transmission FS72 for the Bo 105 was nearing market launch. By 1970, the payload capacity was increased from 1,600 kg to 2,100 kg. The Bo 105 became the world’s only helicopter certified for aerobatics. Production ran for over 30 years, with 1,404 units built.”

1968

New Sports Transmission

The ZF Synchroma transmission S 5-18/3 was introduced for passenger and sports cars, and with modifications, it was also used in light commercial vehicles. The AK 6-80 transmission became highly successful, making it suitable for construction vehicles, all-wheel-drive trucks and buses. The 50,000th heavy-duty commercial vehicle transmission was produced, reaching 100,000 units a year later. Customers included Daimler-Benz, Krupp, Henschel and DAF.

1967

ZF Drives for Water

ZF launches the Z 14 outboard drive from Passau, designed for sport and touring boats with gasoline engines up to 130 hp. In Schwäbisch Gmünd, production begins on the S 4-18/3 passenger car manual transmission, with BMW as the primary customer.

1966

New Series

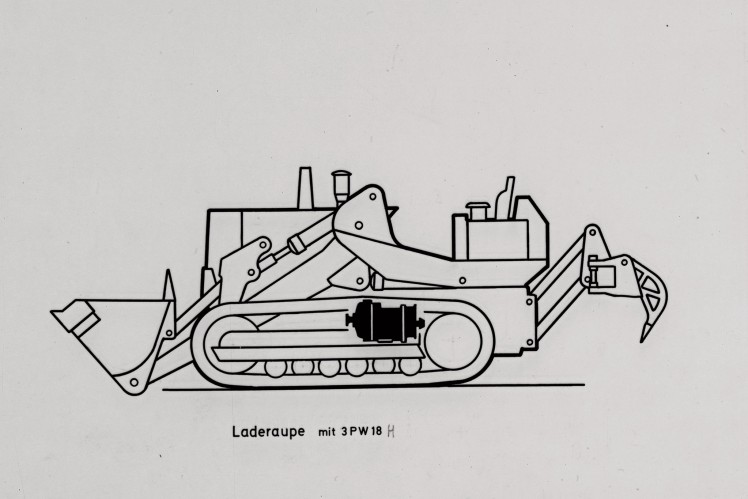

ZF opens a new customer service facility at Plant 2 in Friedrichshafen. The introduction of the ZF planetary reversing transmission 3/4 PW 45 for construction machinery and heavy transport vehicles in Passau marks the beginning of a successful new transmission series.

10/29/1965

ZF Turns 50

On October 29, 1965, ZF celebrated its 50th anniversary with over 700 guests, including Prime Minister Kurt Georg Kiesinger. ZF embodied the economic rise of the Federal Republic and was the largest European specialist company for gears, transmissions, and steering systems in 1965. However, Kiesinger pointed out the end of the economic miracle. ZF needed international perspectives and innovative products.

1965

First Automatic Transmissions

The entry into the production of automatic transmissions for passenger cars in the 1960s was controversial at ZF, but in retrospect, the decision was crucial for ZF’s success. Hansjörg Dach developed the first fully automated car transmission, the 2HP14 with two gears. By 1961, the 3-speed transmission 3HP12 was developed, which was used by BMW and Peugeot. Series production began in 1965, but initial sales numbers were modest.

1964

Customer Service in Australia

Transport Specialties takes over ZF customer service in Melbourne, Sydney, and Adelaide, offering 24-hour transmission overhauls. For heavy trucks, ZF launches the six-speed transmissions AK 6-80 and the fully synchronized S 6-80. The Bölkow BO 46 helicopter is equipped with the FLT 71 rotor gearbox and the tail rotor drive from ZF. ZF begins mass production of the S 4-18 passenger car manual transmission, featuring ZF B-Synchronization.

1963

In Racing Fever

On September 8, 1963, Jim Clark won the Italian Grand Prix and his first Formula 1 World Championship title with a Lotus 25 featuring a ZF 5DS10 transmission. In 1965, he won his second World Championship and the Indianapolis 500. Clark tragically died in 1968 at the Hockenheimring, causing a shock at ZF.

1963

First License for Japan

ZF develops the Hydromedia transmission 2 HP 45 for city buses, featuring two drive gears and an automatic shifting system under the brand name "Busmatic". Two years later, ZF grants its first manufacturing license in Japan.

1962

Large Order from DKW

To manufacture the DKW Junior transmission (4 DS-6-3), ZF expands its production capacity in Friedrichshafen by purchasing part of the former Zeppelin shipyard site. In new Plant 2, after 1.5 years of construction, 200,000 units of this transmission are already produced in 1962.

1961

Entry into Formula 1

The ZF Synchroma transmission 4 DS 10 for front-wheel drive and rear-engine vehicles enters series production. The engine, transmission, and axle drive form a single integrated unit. ZF enters Formula 1, equipping Lotus race cars with the five-speed 5 DS 10 transmission. Starting in 1967, Jim Clark drives the Lotus with a Ford V8 engine and the ZF 5 DS 12 transmission.

1960

Further Expansion

The Passau plant starts production of new products, including the PLA 5000 planetary steering axle and the PSA 7000 planetary star axle, designed for construction machinery. Declining sales of separate tractor powertrains are offset by the addition of planetary axles to the production program.

1959

More than 10000 Workers

For the first time, ZF employs over 10,000 workers across all its plants.

In March, the 100000th commercial vehicle manual transmission of the AK 5-33 as well as S 5-33 series is assembled. The S 5-33 is an advanced version featuring blocked synchronization for forward gears. With its pneumatic shifting aid, it completes the transmission series.

1959

Heading for Brazil

On April 13, 1959, nine ZF employees gathered with their families and colleagues in front of the loading ramp of the Friedrichshafen housing production. Their destination: São Caetano do Sul in Brazil, where ZF established its first manufacturing site abroad. This decision was based on the business relationship with Daimler-Benz, which already operated a plant in Brazil and preferred ZF transmissions for their robustness.

1959

Large Order From DKW

In the 1950s, sales of passenger car manual transmissions fell short of expectations until ZF received a major order from Auto Union in 1959. ZF supplied the 4DS6-3 transmission for the DKW Junior. By 1960, over 65,000 transmissions were produced. A dedicated production line was established, but capacity was quickly exhausted, leading ZF to invest in “Plant 2.” By 1965, over 340,000 units were produced.

1958

Things are Looking up

ZF resumes the development of aircraft drives and begins collaborating with aircraft manufacturers. Production of the A 200 series starts in Passau. Under the "ZF Light Shifting" concept, ZF presents the claw-shifted tractor powertrains A 208, A 216 I, and A 216 II. The constant-mesh transmission AK/S 5-35, designed for construction machinery, buses, and trucks, enters production—eventually selling around 550,000 units by 1990.

1957

New Synchroma Transmission

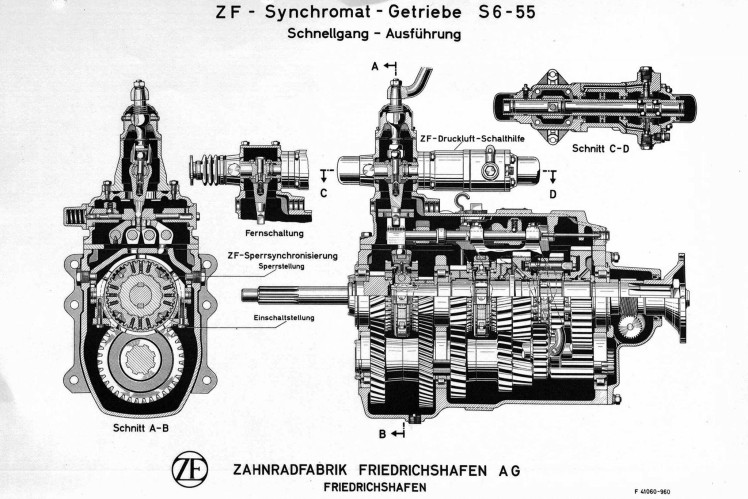

The ZF plant in Passau begins series production of the 3 MD 7 and 3 MD 10 combine harvester transmissions, followed by the 3 MD 9 a year later. These are three-speed gearboxes with sliding-mesh shifting. At the IAA in Frankfurt, the newly developed Synchroma transmission S 4-17 attracts great interest. ZF introduces a pneumatic shifting aid in the Synchromat transmission S 6-55, reducing shift effort for drivers.

1956

Reform in Education

Due to a persistent shortage of skilled workers, training and education became a focus. ZF’s training programs had a good reputation and were continuously improved, yet it was difficult to attract enough young people. With the reopening of the training workshop in the mid-1950s, a cultural shift began: many leadership positions were transferred to more highly qualified employees with the generational change.

1956

The Program Expands

ZF expands its product range with the ZF spindle power steering system, a hydraulic power-assisted steering system. It is particularly suitable for off-road vehicles, trucks, buses, construction machinery, and agricultural equipmentand is adopted by nearly all major manufacturers.

1955

New Jobs

ZF creates 1,600 new jobs. The ZF plant in Passau delivers its 100,000th tractor transmission.

The 50,000th ZF electro-magnetic multi-plate clutch rolls off the production line. Over 1,000 railbuses of the German Federal Railway are equipped with ZF’s six-speed magnetic clutch transmission.

1954

3 HM 60 Transmission for City Buses

ZF integrates a torque converter into the 3 HM 60 transmission for city buses with optional automatic electric control. The BW 800 marine reversing transmission enters series production, launching a new era in marine technology. The VG 500 range-change transmission debuts for special-purpose vehicles with ZF six-speed transmissions. A new generation of claw-shifted tractor powetrains begins with the A 20/18 and A 20/23 models.

1953

Skilled Labor Shortage

In the 1953 annual report, ZF’s board lamented the battle for top talent in the German automotive industry. Competitors tried to poach specialists, and good employees were better paid elsewhere. ZF offered voluntary social benefits as compensation. In 1953, a year-end bonus was introduced to involve the workforce in the company’s success. The reopening of the company health insurance fund was also significant.

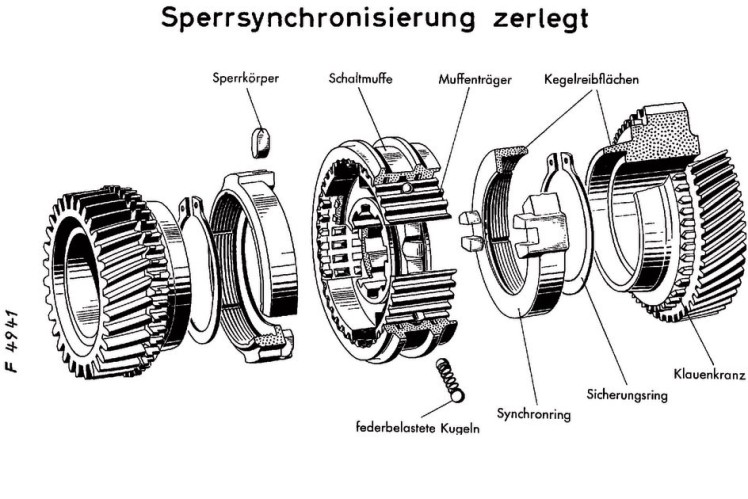

1953

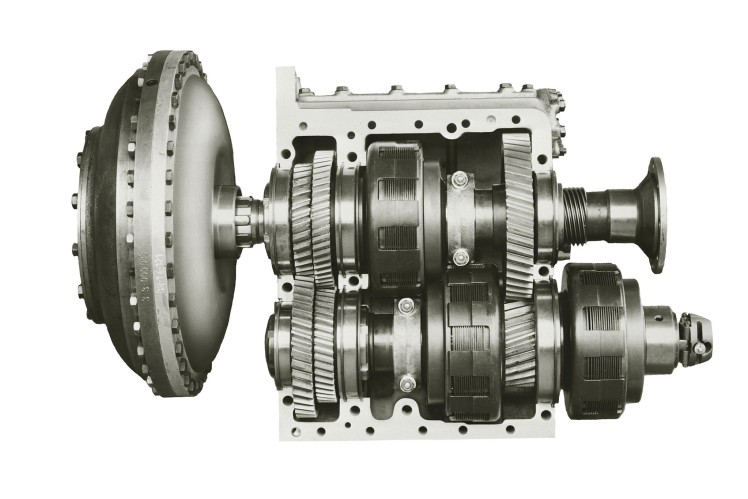

The Gemmer Steering System

ZF acquires a license for the Gemmer steering system from the Gemmer Manufacturing Company in Detroit. The world's first fully synchronized commercial vehicle transmission, the S 6-55 with ZF A-Synchronization, is introduced to the market.

1952

Introduction New A-Synchronization

To offer suitable transmissions for all truck and bus types, ZF expands its lineup of constant-mesh transmissions. Models ranging from AKS 25 to AK 6-75 cover payloads of up to 10 tons. The new ZF blocking synchronization system (ZF A-Synchronization) is introduced in passenger car transmission S 4-15.

1951

From Ross to Gemmer

“In the 1950s, ZF’s production of Ross steering gears declined. ZF partnered with Gemmer Manufacturing in Detroit, whose more robust steering gear with a greater angle gradually replaced Ross’s. Production in the steering division increased significantly. In 1956, the spindle power steering was introduced, establishing steering gear manufacturing as a key pillar at ZF.”

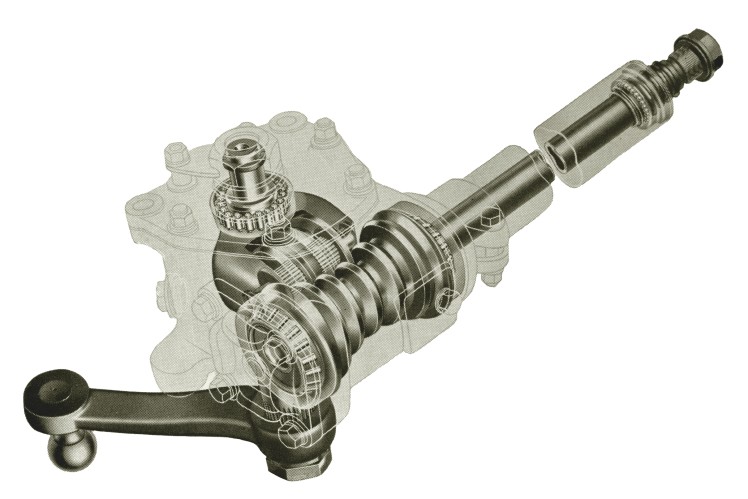

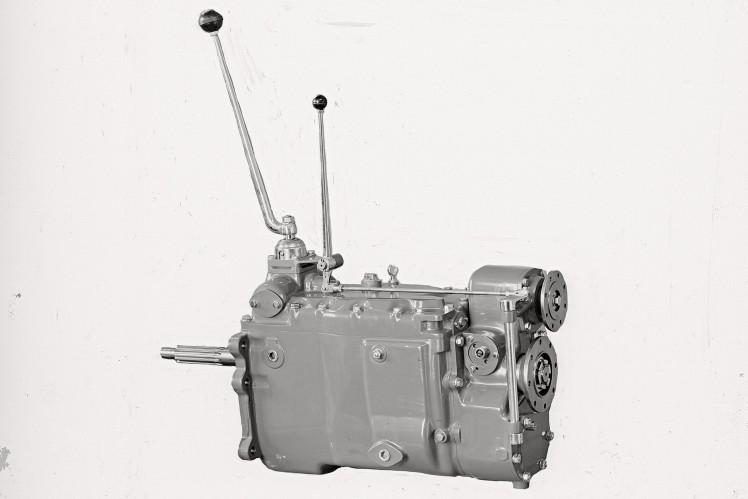

1951

The Media Transmission

ZF introduces a new six-speed Media transmission, equipped with a steel multi-plate clutch and an electric remote shift system. In vehicles fitted with this transmission, the driver only needs to push the gear lever up to shift up and down to shift down, significantly simplifying gear changes.

8/17/1950

New Ownership Structure

After ZF supported the establishment of a French gear factory and behaved constructively after its failure, the French occupation authorities were ready to create stable ownership structures. On August 17, 1950, ZF shares were transferred with 89.8 percent to the city of Friedrichshafen (in the form of the Zeppelin Foundation), to the Brandenstein-Zeppelin family (6.2%), and to the Maag company (4.0%).

1950

Breakthrough With Six Gears

ZF launches mass production of the six-speed transmissions AK 6-50, later AK 6-55 and AK 6-75, as well as the five-speed AK 5-33. These models mark ZF’s breakthrough in the post-war market.

1949

Begin of Multi-Plate Clutches

Small-scale production of multi-plate clutches begins. These clutches, despite their compact size, can transmit high torque and are capable of under-load shifting.

1948

The ZF-Champion

Production of the newly developed A-15 tractor powertrain begins.

ZF grants a license for the Champion vehicle to former racing driver and BMW engineer Hohlbein in Herrlingen near Ulm. His company, following ZF's basic design principles, produces a total of 284 vehicles by May 1950.

1947

The Foundation Moves

After numerous confusions regarding the future of the Zeppelin Foundation and its assets, Count Zeppelin resolved the conflict almost 30 years after his death: The 1908 foundation deed stipulated that the assets would fall to the city of Friedrichshafen if the original purpose could no longer be fulfilled. This happened on March 1, 1947. In July 1947, ZF also came under the control of the French occupation authorities.

1947

Trucks for Reconstruction

Building on years of experience, ZF develops five- and six-speed constant-mesh truck transmissions, AK 6-50 and AK 5-33. Blocked synchronization is introduced only in the development of passenger car transmissions.

1946

Uncertain Future for ZF

The situation was serious for ZF: The LZ Group was subject to the shutdown order. Further assistance could only be expected if ZF separated from the group. Radical measures were proposed, such as re-establishing the company by the workforce and limiting production to agricultural machinery. On July 23, 1946, Hans Cappus resigned; a day later, Hugo Eckener announced his withdrawal as head of the group.

1946

The Subcompact Champion

Between soapbox and classic racing car: In July 1946, Albert Maier, head of the technical office, designed a small car called “CHAMPION” with a 1.4-meter wheelbase, teardrop-shaped open body, exposed wheels, two unpadded seats, and an external rear engine with a tank above it. The goal was to provide commuters with affordable mobility. The car was to reach 40-45 km/h, be simple and economical. Despite the promising concept, the Champion never went into series production, as ZF was busy meeting the increasing demand for transmissions and steering systems.

1945

ZF Producing Again

Since ZF was not considered a pure armaments company, work could be resumed. On May 14, 1945, cleanup work on the factory premises was approved, and from June 6, the production of tractor transmissions was permitted. Under primitive conditions in the basement of Hall V, the production of household appliances began. The restart at the Schwäbisch Gmünd plant went smoothly, and steering system production was relocated there.

1945

The End of the War

On April 29, 1945, the day the war ended, the ruins of the ZF plant were almost empty. Only one employee remained for security. Production and administration had moved to external sites. After the Wehrmacht withdrew, soldiers of the “Première Armée Française” reached the plant, and ZF was tasked with developing a tank drive. However, more important was the revival of the civilian product portfolio.

1944

Destruction

On the night of April 28, the main plant in Friedrichshafen is 80% destroyed in an Allied air raid. The bombing attacks are documented in a situation map.

1943

A New Plant in Passau

To meet production demands, the ZF board and supervisory board had been searching for new locations since 1941. It was decided to establish the subsidiary Waldwerke GmbH in Passau on May 13, 1943. Between March and October 1944, several hundred prisoners from the Mauthausen concentration camp were employed alongside nearly 2,000 civilian workers. The highest recorded number for this group is 334 (as of September 23, 1944).

1942

Special Challenges

As early as 1937, the LZ Group decided that the tank transmissions developed by Maybach should primarily be manufactured in the plants of the Zahnradfabrik. In 1942, the ZF board faced the challenge of mass-producing the Olvar transmission. ZF developed the 7-speed manual transmission AK7-200 for the “Panther.” By the end of the war, over 6,200 of these transmissions had been built, which were also used in the “Tiger.”

1942

Expansion in Alsace

ZF purchases land in Schlettstadt (Sélestat), Alsace, with plans to relocate steering system production there.

1941

Forced Labor

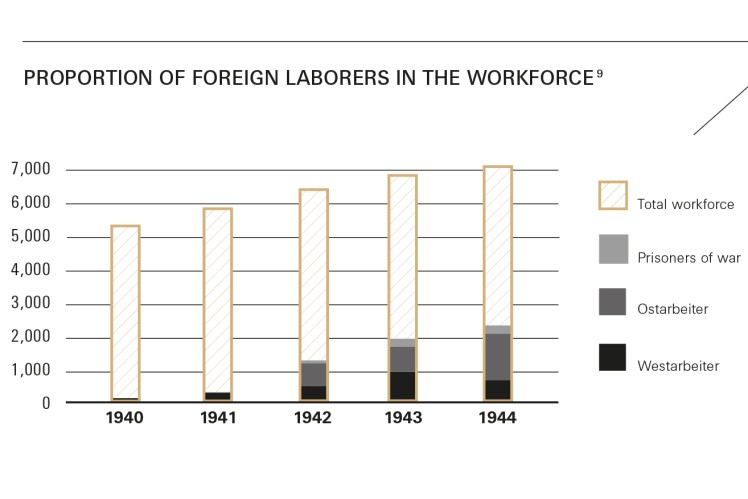

The Nazi regime urgently needed labor as more German men were drafted into the Wehrmacht. Therefore, people in Europe were forcibly recruited. The first foreign workers at ZF even came voluntarily, with 83 counted in 1940. Between 1941 and 1942, the number of forced laborers at ZF increased from 311 to 1,456. In total, more than 2,800 forced laborers were employed at ZF.

1940

25 Years of ZF

ZF celebrates its 25th anniversary and shares company profits with employees through a jubilee bonus.A new customer service center is established in Vienna-Inzersdorf, operating until 1945.

1939

The Inferno Begins

With the invasion of Poland on September 1 and the subsequent declarations of war, World War II begins—an inferno that will cost millions of lives. ZF supplies the German Reich with six-speed Aphon tank transmissions (SSG 45, 46, 76, and 77). For wheeled vehicles, five-speed FAK transmissions are produced in two sizes.

1938

Customer Service in Dortmund

ZF opens a customer service center in Dortmund and establishes the Zeppelin Pension Fund to provide financial security for its employees. Additionally, ZF develops passenger car and truck transmissions with electromagnetic clutches—the first under-load shifting transmissions, though they are never used in vehicle production. In Schwäbisch Gmünd, production of limited-slip differentials begins.

1937

Tractor Transmission A12

In 1937, ZF introduced the A12, a 4-speed transmission for tractors. It featured a block design where the engine, transmission, and rear axle formed a single supporting unit. The package also included the differential with a lock and other components. Production began in Friedrichshafen and was moved to Passau in 1946, where 3,052 units were built. In 1948, the A15 followed with additional gears.

1936

Production Program Grows

Anton Ryba from Innsbruck patents an electromagnetically operated multi-plate clutch, which reduces overall sizethrough increased friction surface area. ZF secures the license for this innovation. Additionally, the six-speed transmission SSG, a variant of the Aphon transmission, is increasingly integrated into the production program—designed for use in tanks.

1935

First Autobahn Overdrive

For the first time, ZF experiments with a marine reversing transmission. To make passenger cars suitable for highway use, ZF develops the Autobahn Overdrive FE 15/20/30. Using a planetary design, an additional fifth gear can be added, ensuring economical and safe driving at high speeds.

1934

Fully Synchronized

In 1934, ZF presented a transmission with helical gears for all forward gears. The gear pair for first gear was in constant mesh. The gears were narrower, saving costs and weight. The “Allsynchron” transmission synchronized all gears and used synchronizer cones. It was designed as a 4-speed transmission for cars, with an optional fifth gear for economical driving at high speeds.

1933

Political Priorities

The Nazi takeover led to the adaptation of existing technologies to new political priorities. Based on Aphon transmissions, ZF adapted civilian transmission designs for military use. In 1935, ZF, in collaboration with Maybach, developed a more powerful version, the FG31. ZF continued to generate the majority of its revenue from civilian products and developed a “highway overdrive” for higher speeds.

1932

Growing Comfort

The spiral transmissions AKS 15 and AKS 20 are four-speed transmissions developed for passenger cars, featuring cone synchronization and helical gearing in the upper gears. The five-speed transmissions FAK and FAKS, designed for trucks, share the same characteristics and are quiet and easy to shift. ZF supplies around 80,000 transmissions for the Daimler 170 V passenger car alone.

1932

Start of Steering Systems

During the Great Depression, ZF, focused on transmissions, risked ruin from a single wrong decision. Alfred von Soden proposed manufacturing steering systems and partnered with Ross Gear and Tool Company. In 1932, ZF received an exclusive license for Ross steering systems in Europe. Ross was acquired by TRW in 1964, and ZF took over TRW in 2015, closing the historical circle.

1931

The Freewheel Patent

ZF files its first freewheel patent. The design goal is to enable gear shifting without intermediate throttle and without double clutching. Instead of multiple synchronizations, a freewheel mechanism is intended to reduce fuel consumption and production costs.

1930

Synchronous with Aphon

With the introduction of lamella synchronization for the Aphon transmission, ZF achieves another breakthrough. The new Aphon four-speed transmission with reverse gear shifts in first and reverse gear using a sliding gear. It is the first synchronization mechanism in a ZF transmission.

1929

Recipe Against the Crisis

In 1929, the global economy experienced a dramatic downturn with the stock market crash on Wall Street in New York. ZF had access to the best manufacturing technologies of the time for straight and helical gears and had significant inventors in-house. ZF’s commercial success with their standard and Aphon transmissions, a four-speed gearbox with three quiet gears, helped maintain a stable workforce.

1929

A Silent Transmission

Luxury car manufacturers were particularly interested in quieter alternatives to the generally noisy transmissions of the time. In 1925, ZF engineers began using Minerva helical gears for quieter transmissions. The first production-ready gearbox utilizing this technology in the second, third, and fourth gears was completed in June 1929. It was named ‘Aphongetriebe’ (Greek for ‘without sound’) through an employee contest.”

1929

Shifting Becomes Easier

To avoid noise from clumsy shifting, synchronization was necessary to automatically adjust the speed during shifting. Therefore, ZF developed a space-saving multi-plate clutch that fit the design of the Aphon transmission. Initially, only the top three gears were made easy to shift through synchronization. However, partially quiet transmissions could only be a temporary solution.

1928

Planetary Gearbox for LZ127

The LZ127 transmissions, designed by Luftschiffbau Zeppelin GmbH and produced by ZF, are planetary gear systems that reduce the full power of a Maybach 12-cylinder engine with 542 HP from 1,600 to 800 revolutions per minute.

1927

Major Order from MAN

A key ZF customer, MAN in Nuremberg, secures employment at ZF with an order volume exceeding 500,000 Reichsmarks and additional large contracts. The three-speed transmissions DKb, DKb 20, and DKb 35, as well as the four-speed transmission K 35, expand the product range. The external drives AC and AS enhance the application possibilities of the universal transmissions.

1926

Large-Scale Production Starts

With the universal transmission, large-scale production can finally begin. The transmission types and series of the universal transmission are continuously improved and expanded. For a long time, they remain the main products of ZF. A total of around 300,000 units are sold.

1925

Unity Instead of Diversity

Under the motto "Unity instead of Diversity," a small group of engineers designs a standardized transmission of simple construction: the universal transmission—initially for medium-sized trucks. The core idea is to develop various applications ready for production and adapt the variations to different tasks and engine power levels. This approach follows the American model.

1924

New Maag Dial Gauge

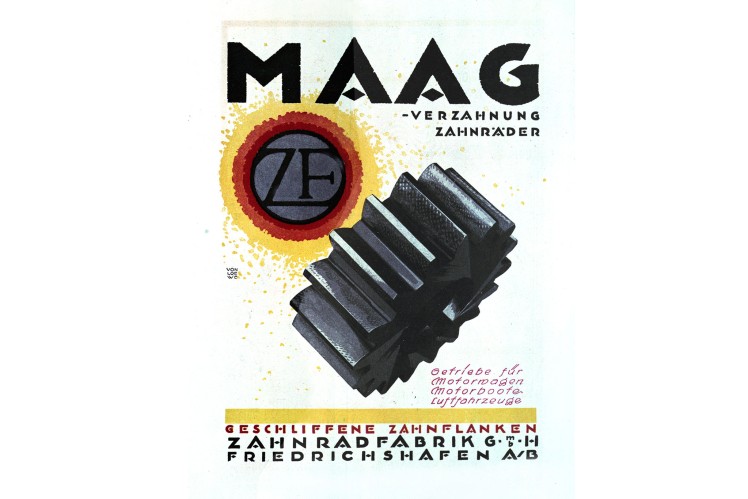

The transfer of the reparations airship ZR III (LZ 126) to the USA draws worldwide attention to Friedrichshafen. The Zeppelin Group assumes full financial liability for its safe delivery. ZF invests heavily in precision measuring instruments. The gear grinding department gains valuable experience using a new Maag measuring gauge and a Zeiss microscope, highlighting the growing importance of quality control.

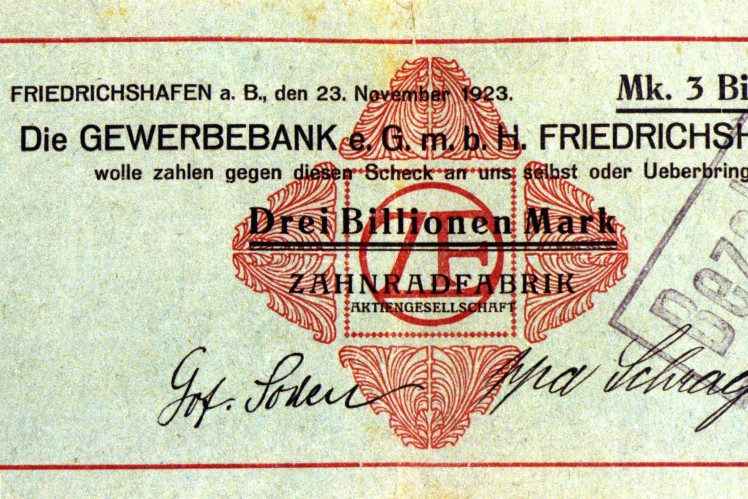

1923

License to Print Money

In 1923, post-war inflation in Germany spiraled out of control. ZF began printing its own emergency money at the Gessler printing house, and wages were paid daily. The 1923 balance showed a surplus of 81.2 quadrillion paper marks, but this was purely nominal. The situation stabilized with the introduction of the Rentenmark on November 15, 1923. By 1924, ZF could present an orderly balance sheet again.

1922

Cost-Cutting is the Motto

ZF employs more than 550 people. The six engineers in the design department are tasked with developing a standard gearbox that ensures reliable power transmission while adhering to Henry Ford's cost-efficiency principles.

1921

The Soden Transmission

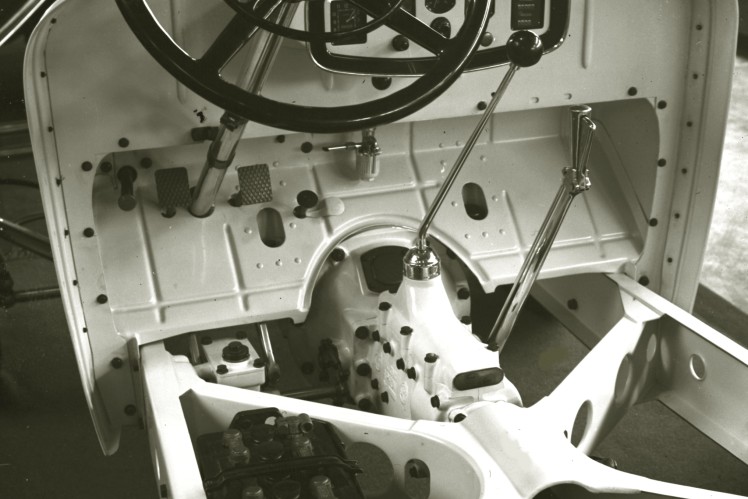

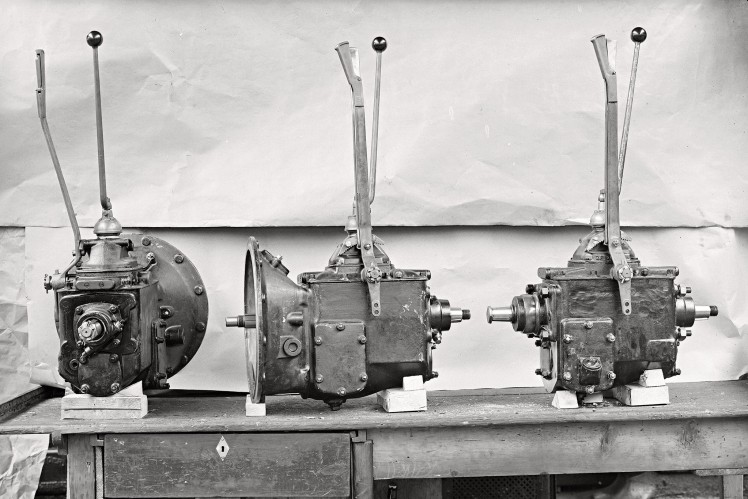

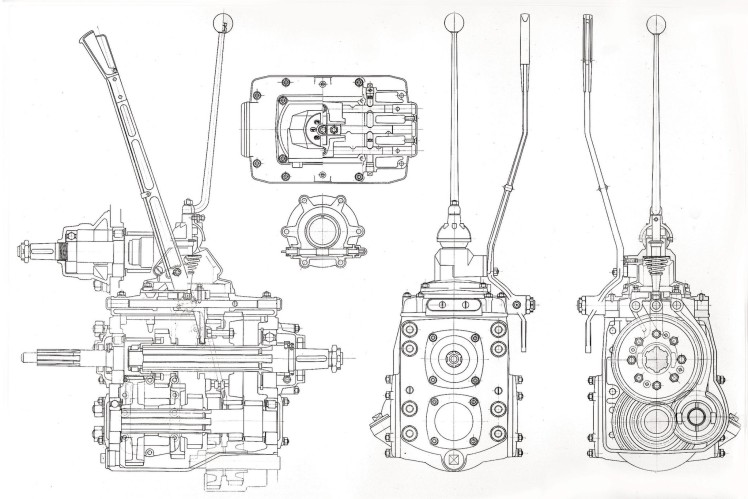

With the establishment of the corporation in May 1921, Alfred von Soden transferred all patents in his name for a semi-automatic transmission he developed to ZF. The so-called Soden transmission was far ahead of its time: The gears could be preselected at any time using a switch on the steering wheel or dashboard and then engaged by pressing the clutch pedal - the first step towards an automatic transmission.

1921

ZF Becomes a Corporation

Hardly six years after its founding, ZF faced liquidation. The shareholder Maag Group was not willing to provide additional funds. Alfred Colsman, the representative of the majority shareholder Luftschiffbau Zeppelin GmbH (LZ), therefore proposed the transformation into a corporation. Thus, on May 27, 1921, Zahnradfabrik Friedrichshafen AG was founded, with the capital shares between LZ and Maag distributed in a ratio of 80:20.

1920

The ‚Billet‘ Gearboxes

The so-called "Knüppel" gearboxes for passenger cars are developed to production readiness and added to the manufacturing program. These gearboxes serve as a design model for the later successful standard gearboxes. The new three-speed gearboxes, with the shift lever positioned at the gearbox center, are produced under the type designation „K.

1919

First Three-speed Gearbox

Despite low chances of selling complete gearboxes, ZF develops a simple three-speed gearbox, introduced to the market as the 8-horsepower automobile gearbox.

1918

General Upheaval

With the end of World War I, political and social upheaval begins. The workforce decreases from 444 to 261 employees by the end of the year. To ensure social security for employees, an independent company health insurance fund is established. The necessary post-war shift towards motor vehicles leads to a restructuring of production.

1916

The First Patents

ZF registers 10 patents, including the Soden gearbox, developed to production readiness for automobiles. As airplanes gain importance during the war, the demand for reduction gearboxes for aircraft engines grows. Versuchsbau GmbH Gotha-Ost orders 40 combined gearboxes for twin 260-horsepower engines from ZF for the giant aircraft developed on behalf of Count Zeppelin.

1915

The Best Gears

ZF's founding, which took place on August 20, 1915, under the name of "Zahnradfabrik GmbH" with headquarters in Friedrichshafen, Colsman and Soden were in fact able to secure the exclusive license in Germany for the distribution of gears and transmissions according to the Maag system. Already the first ZF company agreement mentioned implementing such transmissions in motor vehicles and motorized boats as well.

130 Years of Innovation History

Schweinfurt Site Celebrates Anniversary

From the beginnings as Fichtel & Sachs in 1895 to today as a key ZF location – Schweinfurt looks back on 130 years of innovation and transformation. At the heart of it all are the people whose expertise, passion, and ideas have shaped the site.

To mark the anniversary, they share their stories – of challenges, successes, and technological breakthroughs.

Video: From Gear Factory to Global Player

Watch the video to discover how the company has taken the technological lead globally since then.

Biographies

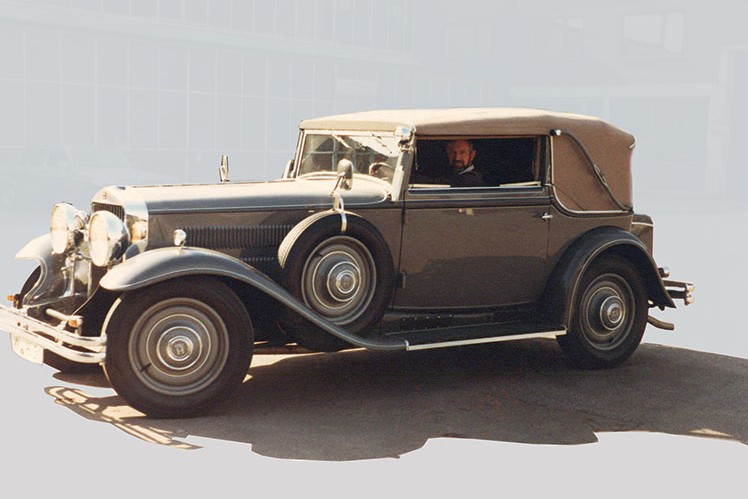

Stories about Classic Cars and Heritage

ZF has a history of over 110 years. During this time, countless vehicles from different customers were equipped with innovative ZF products. These websites inform and entertain you about ZF's historically mobile heritage: with stories about classic cars, modern classics, and about what you need to know about the products. We wish you lots of fun and interesting information with ZF!

125 Years of Opel: Trendsetter with Tradition

Opel celebrates 125 years of automotive engineering - full of innovations for every customer. The brand stands for the tradition of bringing technical achievements to life in an intelligent way and moving quickly into series production. ZF products were not to be missed...