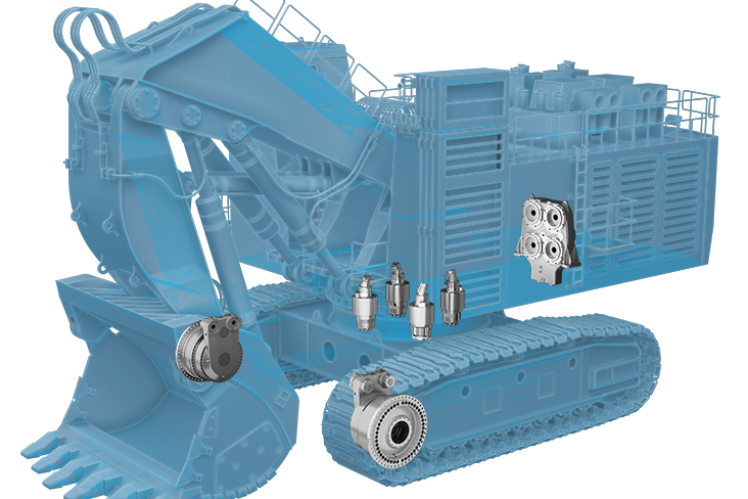

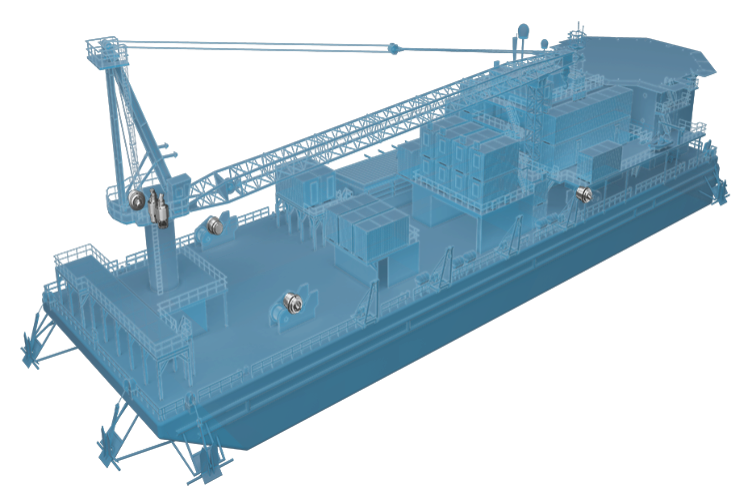

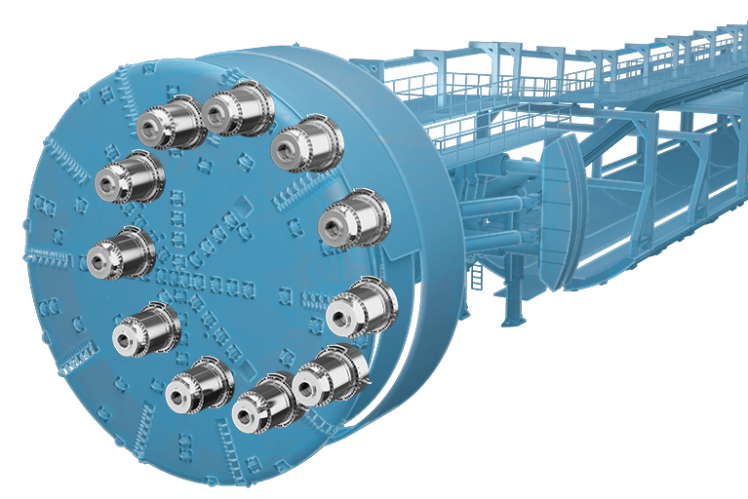

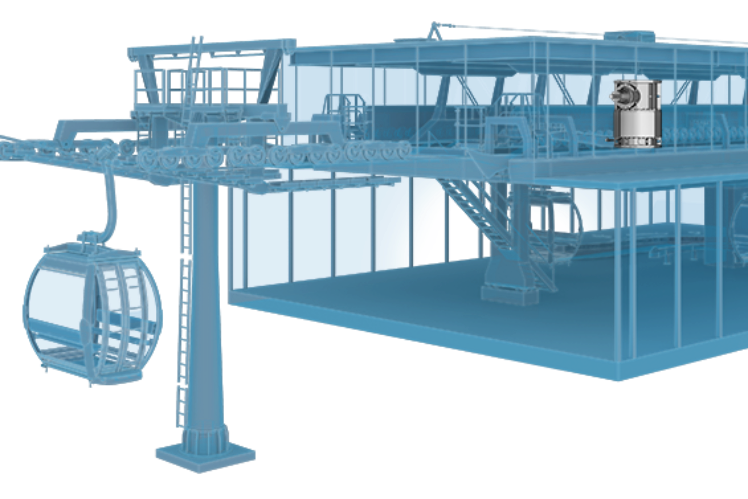

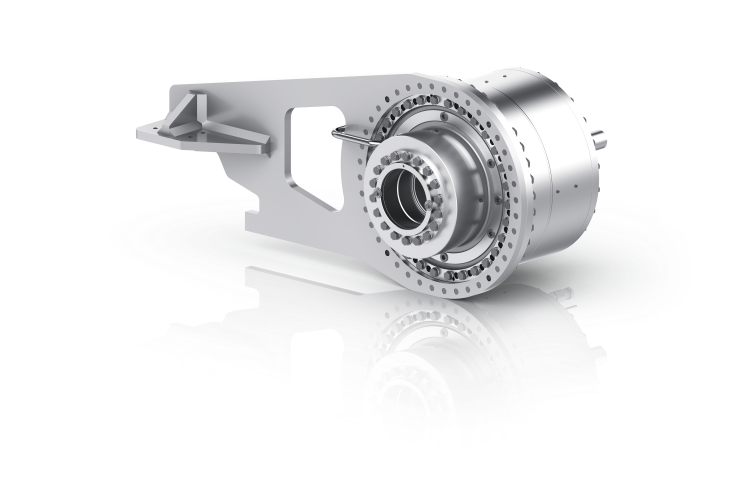

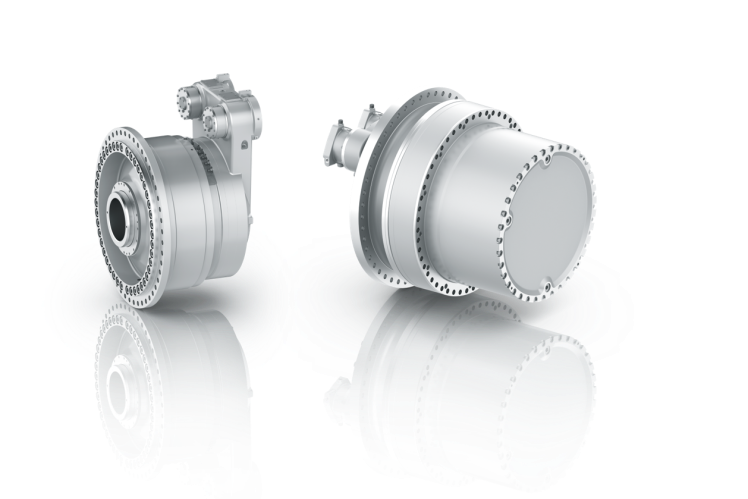

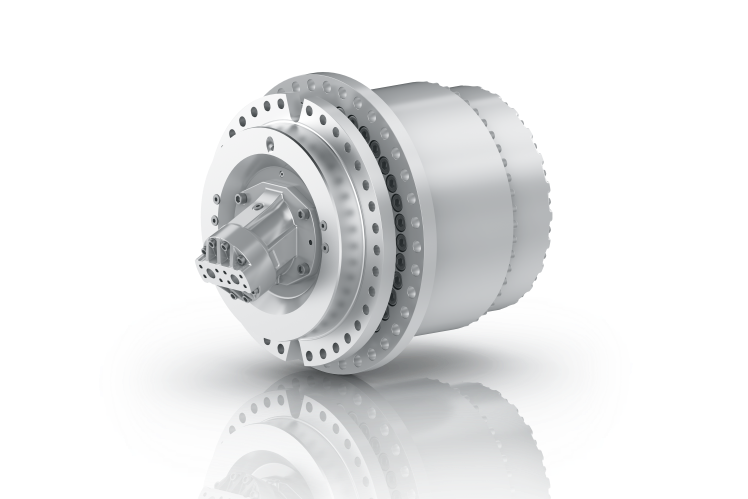

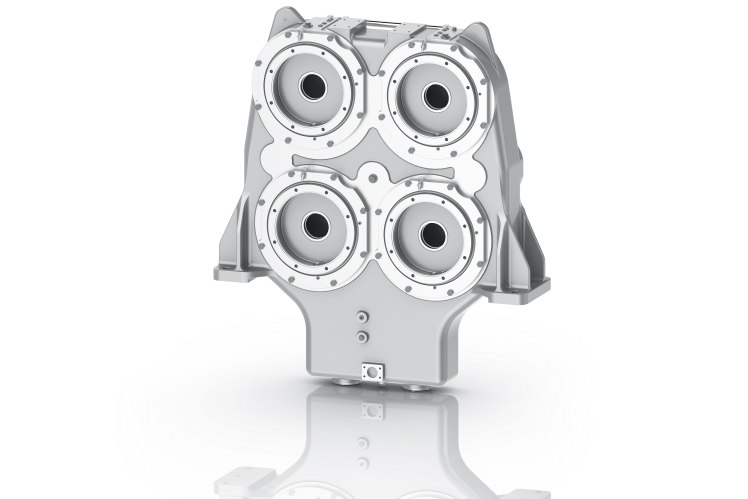

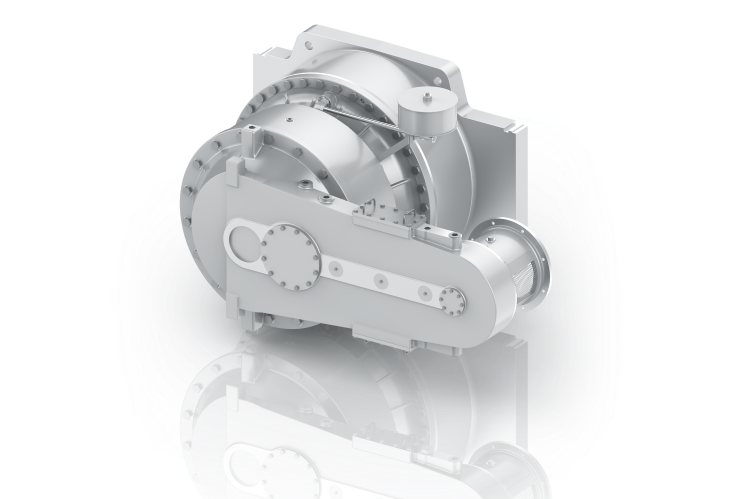

Predictive maintenance of the gearbox resp. coupling or clutch increases the availability of your machine or plant and improves the efficiency in operation. Our qualified service technicians possess extensive experience in detecting damage at an early stage with the assistance of proven inspection programs and modern measuring- and testing equipment.

early detection of damages