Mechanical Engineering Based on Almost 100 Years of Experience in the Automotive Industry

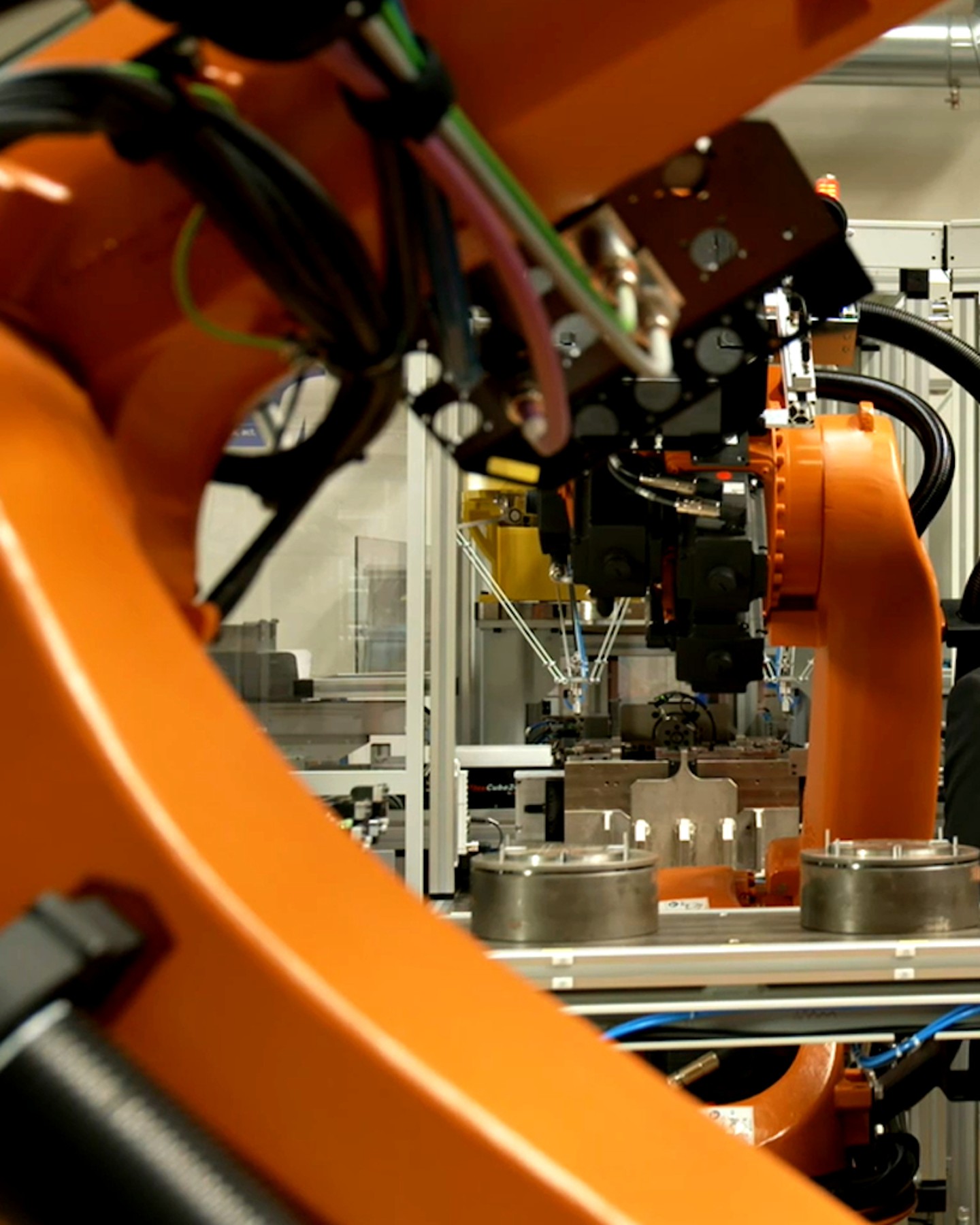

With approximately 185 employees in Development, Production and Commissioning, we are able to supply special machines to our customers around the globe. This results an annual sales volume for internal and external customers in the middle double-digit million range.

Being part of a technology group which is a global player as well as with our experienced and highly motivated employees, we are in the best position to shape the challenges of the future.

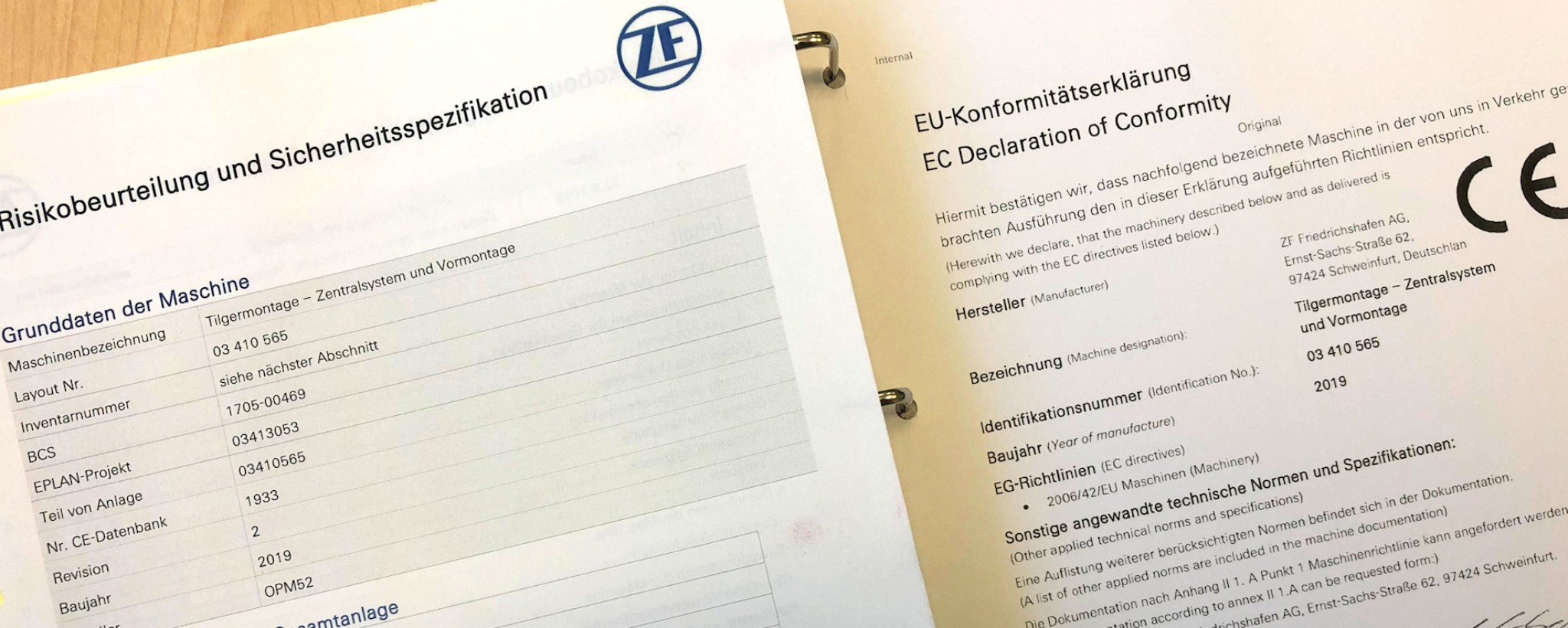

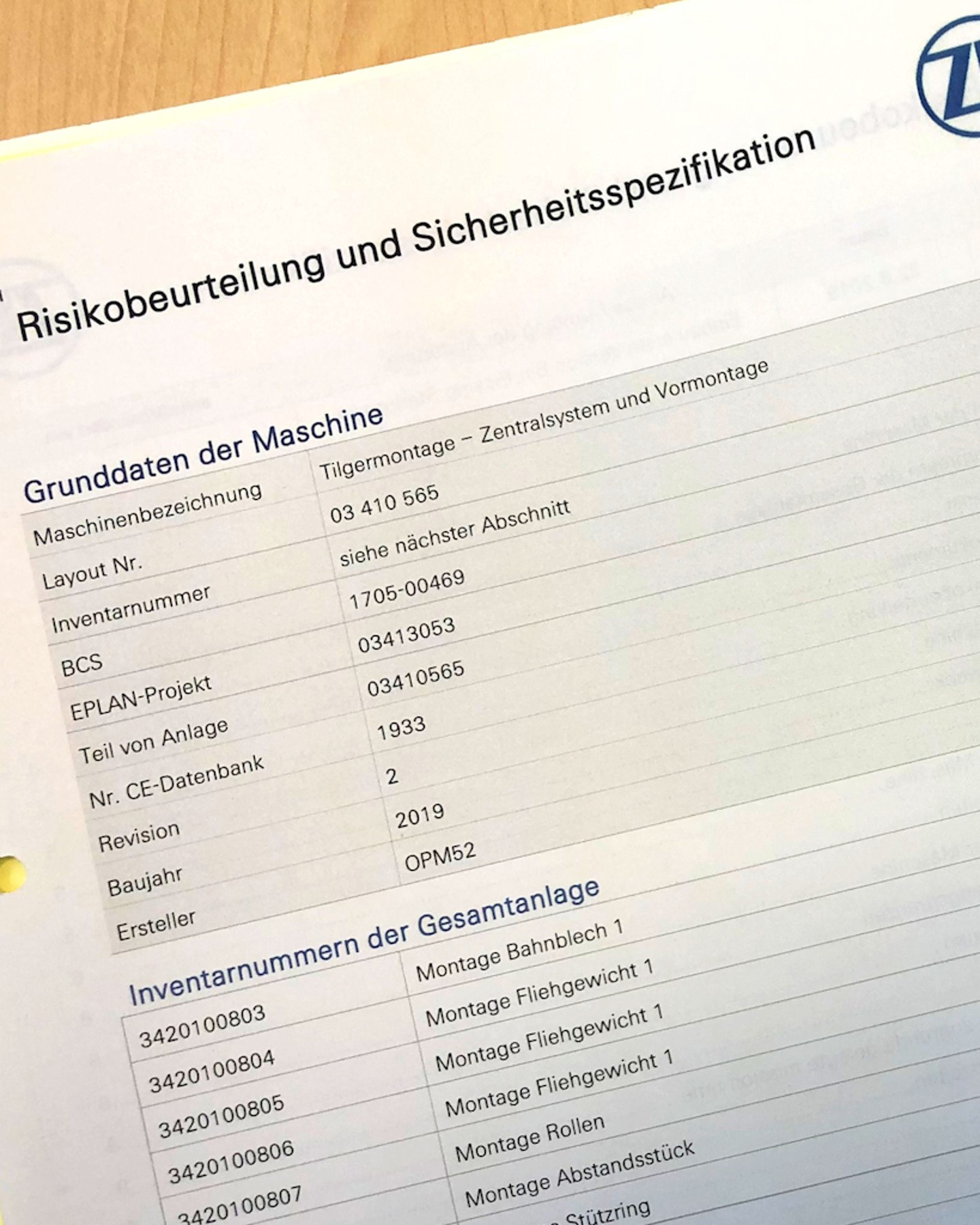

The development and construction of customized machines for products of the future are at the core of our work, which we are passionate about. Focusing on development and standardization, virtual reality as well as in-house software development enables us to deliver machines at a higher maturity level.