CeTrax - Electric Central Drive

System expertise for electrically driven special vehicles

CeTrax animation

Key Facts

What can CeTrax - Electric Central Drive provide?

The CeTrax electric central drive can be integrated simply into vehicle designs with a conventional driveline layout and is suitable for a variety of special vehicles such as terminal tractors, light crane vehicles or municipal vehicles. The ZF system with inverter and electronic control unit with proprietary ZF software provides vehicle manufacturers with a system package that is designed for cost-effectiveness and efficiency.

Details

Product Details

The compact power package: Zero-emission solution for vehicles with conventionally designed driveline

The CeTrax system is an all-electric central drive that can be used in different buses, trucks and a variety of special vehicles like terminal tractors and body carriers. Installed in battery-driven vehicles, the system operates with zero local emissions!

The focus is on manufacturers that want to integrate an electric drive into their existing conventional vehicles. It is suitable for replacing internal combustion engines in special vehicles in conventional arrangements or to retrofit existing axle driven vehicles without changing the powertrain concept. CeTrax saves on costs and reduces the workload involved in technical integration as well as in service. With a maximum power output of up to 300 kilowatts and a maximum torque of 4,500 newton meters, CeTrax is second to none in terms of performance when compared with a classic drive.Just like all commercial vehicle electric drive systems from ZF, the CeTrax system is supplied complete with inverter and electronic control unit. The customer receives a perfectly harmonized system in terms of performance, efficiency and service life. ZF supplies the complete package - from development to service topics - from a single source.

Benefits

The sustainable drive solution for logistics centers and ports

Sustainability and associated electric mobility are central issues of an increasingly globalized world. Logistic centers have a special responsibility in terms of dealing with resources and environment as they are handling a lot of tasks like internal transport, storage, delivery and assembly of goods.

Requirements for logistic hubs are increasing with the demand for more efficient, clean and quiet vehicles.

Terminal Tractors are specialized vehicles used for movement and handling of container chassis and semi-trailers in ports and logistic centers. With the CeTrax electric central drive, ZF offers a sustainable and locally emission-free alternative for terminal tractor fleets and operators.

Sustainability and associated electric mobility are central issues of an increasingly globalized world. Logistic centers have a special responsibility in terms of dealing with resources and environment as they are handling a lot of tasks like internal transport, storage, delivery and assembly of goods.

Requirements for logistic hubs are increasing with the demand for more efficient, clean and quiet vehicles.

Terminal Tractors are specialized vehicles used for movement and handling of container chassis and semi-trailers in ports and logistic centers. With the CeTrax electric central drive, ZF offers a sustainable and locally emission-free alternative for terminal tractor fleets and operators.

Advantages

- All-electric, low-noise and zero-emission operation

- ZF system including inverter and electronic controls means optimized performance and simplified vehicle homologation

- High system efficiency for extended service hours between recharging periods

- Use in combination with conventional axles and common ratios is possible

- High performance power at low weight due to combination of water and oil cooling

- Provides interface for autonomous driver readiness

- Suitable for types of special vehicles up to 90 tons

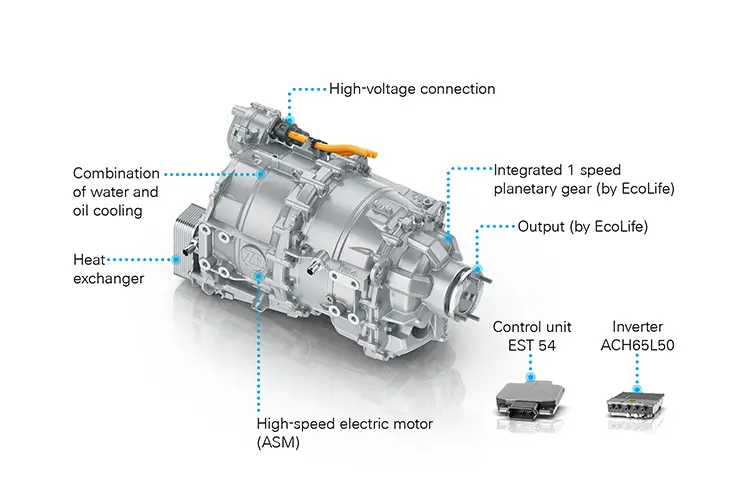

The CeTrax system - Scope of delivery

High reliability and safety by using proven volume production components:

- Electric motor with integrated, tried-and-tested planetary reduction gear stage from ZF - EcoLife

- EST 54 electronic control unit

Electronic Control Unit EST 54

The ECU (Electronic Control Unit) vehicle network connector is part of the standard electronics for various ZF products and is characterized by high reliability and safety as well as by its resistance to temperature and mechanical shock (IP67). The network connectors forms the interface to the vehicle's electrical system with standard communication interface (SAE J1939).

Functions:

- Wide range of standard functions

- Vehicle-specific adaptation of the software for optimal performance

- Diagnostics via ZF-TESTMAN, 24 hours monitoring / 7 days a week

- Many optional functions for adapting to customer requirements

Inverter ACH6530

The 3 phases drive inverter by InMotion has a nominal voltage of 650V.

Highlights:

- Dimensions (in mm): 421 x 362 x 122

- Weight: 20 kg

- Degree of efficiency: up to 98%

- Liquid cooling

- Protection class: IP6K9K

Customer Voices

"ZF and Terberg have been business partners for 50 years and working on the integration of CeTrax into our new generation of electric vehicles gave us the opportunity to deepen this long-term relationship. The lines with ZF engineering are short, which contributes to the most optimal coordination."

Ronald van Zoelen, Engineering Manager at Terberg Benschop

Additional information

Press Release: Keeping the world's freight moving efficiently and with zero emissions: ZF-CeTrax for Terminal Tractors