100 Years ZF Rail Technology

In 2024, ZF celebrates its 100th anniversary in the rail market: The first time ZF developed a drive system for railcars was in 1924. In the decades that followed, the company further expanded its position as a supplier of railway technology. This was achieved through expansions and acquisitions, as well as through a strong international presence.

Today, ZF boasts an impressive portfolio serving numerous rail vehicle manufacturers and operators worldwide. Additionally, the company stands out for its attractive digital offering.

Video: A Century on Track

Milestones in ZF's history in the rail sector

The foundation stone: TS18.5 Soden transmission

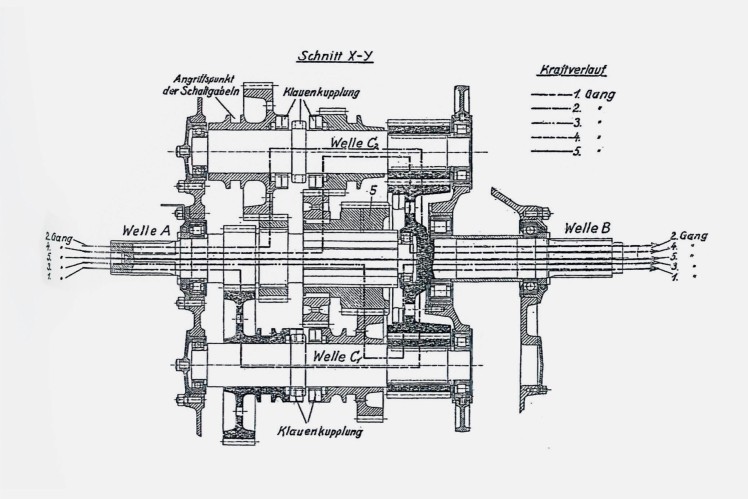

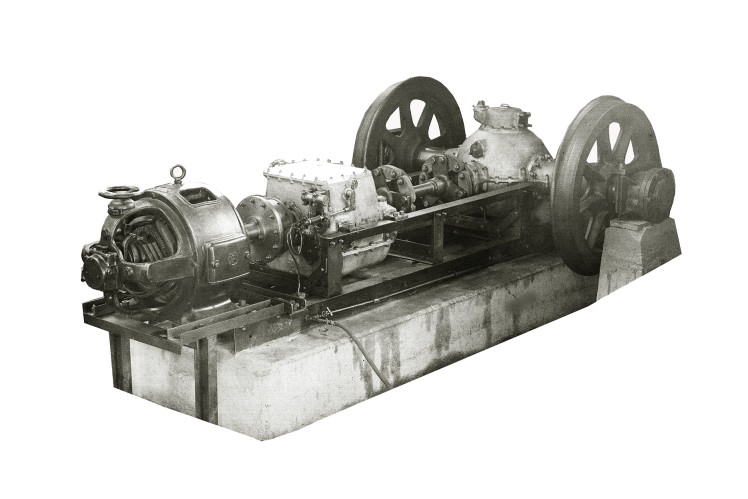

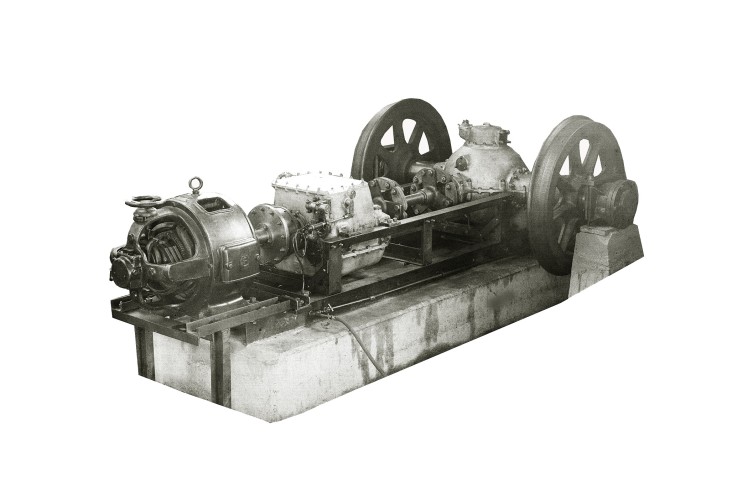

Comfort and efficiency have always been important, and this holds true for railway technology as well. With the advent of combustion railcars at the beginning of the 20th century, the aim was to maintain engines at the ideal operating point using a transmission. The shift points were designed to be so gentle that passengers and objects aboard wouldn't be disturbed. The corresponding transmission technology came from ZF for the first time in 1924, as evidenced by a sketchbook entry. The company from Friedrichshafen, which had been established a mere nine years prior, adapted an invention of its then boss, the TS18.5 Soden transmission, so that it could be used in rail vehicles. The transmission was a forerunner of the automatic transmission systems that would come later. At that time, it already allowed the preselection of the next gear step and a correspondingly smooth gear change.

Recipe for success: innovation capacity through technology transfer

This starting point represents the inception of a strength that ZF can still leverage today: technology transfer.

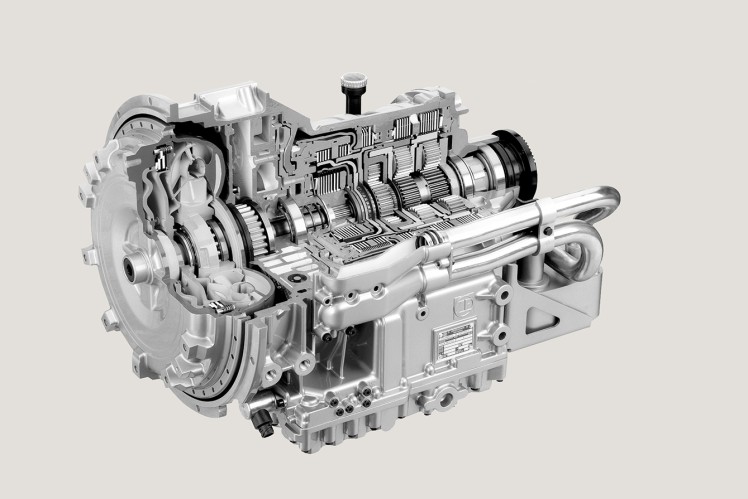

Building on the blueprint from the early years, ZF later modified the Ecomat multi-ratio transmission to develop Ecomat Rail (predecessor of the current EcoLife Rail), and adapted the AS Tronic automated manual transmission to create AS Rail, specifically to meet the needs of diesel multiple units. However, ZF has also supplied mechanical drive components for electrified trains since the early days and continues to do so today for a wide range of rail vehicles. These include metros, trams, electric multiple units, high-speed trains, diesel multiple units, locomotives and special vehicles.

Worldwide on track

ZF products are now indispensable in rail vehicles around the globe. The rapid transit trains in almost all major cities around the world – from Istanbul to Shanghai to Lima – rely on ZF technology. ZF yaw dampers stabilize the swift and comfortable travel of high-speed trains operating in China or connecting mainland Europe with Great Britain via the Channel Tunnel.

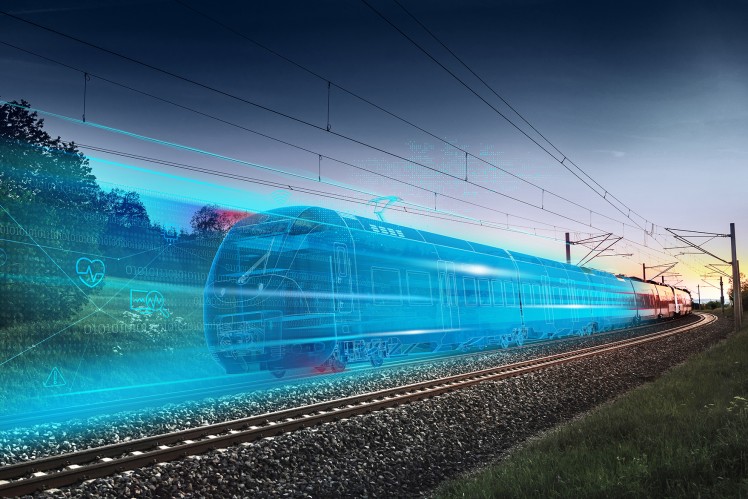

Digital services complementing hardware

With the connect@rail condition monitoring system, ZF has expanded its offering to include attractive digital services. It helps to make the operation and maintenance work more predictable and to avoid failures and downtimes. Also, connect@rail can monitor rail infrastructure to facilitate better planning for repairs.

In railway technology, maintenance and repair are important, as is repowering (i.e., equipping existing rail vehicles with new drive units). Here, ZF's railway technology customers can benefit from the worldwide presence of the ZF Aftermarket Division, which provides fast spare parts, technical information and flexible service offerings.