Intelligent Trailer Program Fuel and CO2 Reduction

Functions to maximize fuel efficiency and to reduce CO2 emissions

Key Facts

What can Intelligent Trailer Program Fuel and CO2 Reduction provide?

These Intelligent Trailer Program functions aim to maximize fuel savings via automation, designed to work with minimum driver intervention. The functions allow the trailer to provide significant fuel and CO2 emission savings of the combined commercial vehicle, helping fleet and cargo owners to meet CO2 emission reduction goals.

Details

OptiTire

Advanced tire monitoring system

- Leverages tire pressure and temperature information to provide precise tire monitoring

- Helps to avoid under-inflation, to reduce fuel consumption and to extend tire life

- Early tire issue detection helps to prevent the risk of tire blowouts, improving safety and vehicle uptime

- Offers internal and external wheel sensors, including simple to install strap-mounted sensors covering all rim sizes and applications

- Alerts driver to pressure loss via truck dashboard, OptiLink smartphone app or SmartBoard making journeys safer and more economical

- Provides real-time fleet notification via telematics connectivity

- Enables fuel savings of up to 2% and a reasonable reduction of CO2 emissions

OptiFlow

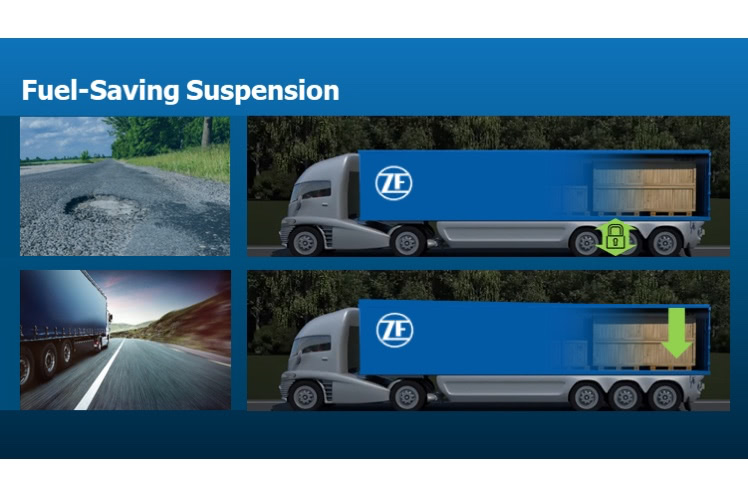

Fuel Saving Suspension

Optimizes trailer height while driving

- Distance sensor connected to the trailer axle recognizes dynamic movements of the chassis caused by uneven roads, curves and braking

- Automatically controls chassis height while driving allowing for improved stability and fuel economy

- Only uses air from the compressor if the Fuel Saving Suspension adjusts chassis height

- Helps to save repair costs by avoiding bouncing, oscillating and cramping of air bellows

- Increases the life of the compressor on the truck, due to reduced charging cycles

- Enables fuel savings also by lowering the trailer end at highway speed providing an aerodynamic advantage

- Helps to save up to 150 liters of fuel and to reduce up to 407 kg of CO2 emissions per truck per year compared to conventional air suspension

- Can be retrofitted up from Premium TEBS E2

Lift Axle Control

Automatic lift axle height adjustment of empty trailer

- The lift axle is automatically lifted without driver intervention when the trailer is empty, optimizing operational efficiency

- Trailer EBS measures the load on the trailer axles and automatically lifts or lowers the lift axle depending on the trailer load

- Automatically respects the total permitted load of the axles

- Up to two lift axles can be controlled separately from each other

- Helps to reduce CO₂ emissions and fuel consumption

- Reduces tire wear and rolling resistance on lifted axles while maintaining stability

- A broad range of solutions that can be applied to lift and tag axles