Lord of the Winds

If it weren’t for Wim Geens’ work, his customers could face massive costs. When wind turbines stop, no electricity is generated and costs just explode. By 2050, electricity will be the main source for fuel and cover more than 50 percent of the world's entire energy demand.

Experts from the International Renewable Energy Agency state that wind power will be one of the most important sources. Wim Geens plans and develops test setups for wind turbine gearboxes and powertrains at ZF Wind Power in Lommel, Belgium.

"It’s gigantic! I’ve never seen anything bigger in my life. You can’t imagine the size of the next-generation powertrains, until you’ve seen them. If you only know the model of the turbine, reality will blow your mind," says Wim Geens enthusiastically. He is responsible for the design of the no-load test setups at ZF Wind Power. No-load tests on a test bench examine the performance and reliability of wind turbine gearboxes Geens is working in the Test and Prototype Center that will host the world's largest system test bench for wind turbines, which is more than 60 meters long and has the highest power rating of 30 megawatts. This unique complete powertrain test bench is currently being built in Lommel, Belgium,in the ZF Wind Power plant.

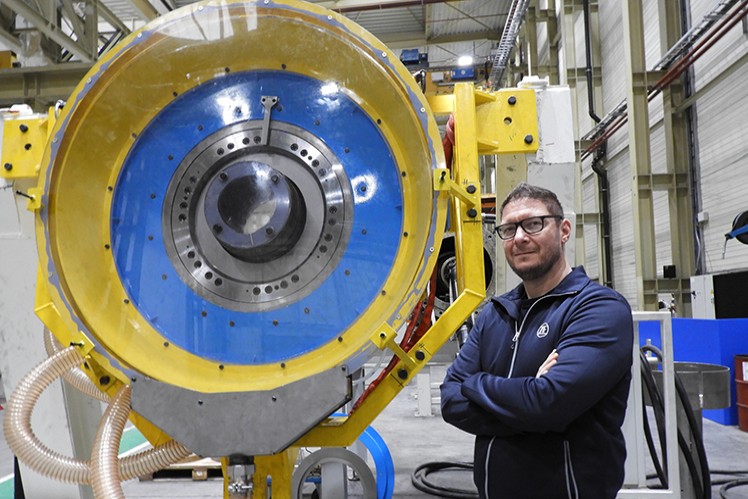

Wim Geens is responsible for the design of the no-load test setups at ZF Wind Power.

Why put gearboxes, main bearings and generators through their paces? It’s quite simple. The force of the gusty winds acting on wind turbines is enormous. The strain and direction of the wind are constantly changing, whether onshore or offshore. This places a heavy strain on the powertrain, i.e., the generator, the main bearing assembly and the gearbox (including rotating parts such as gears, couplings and bearings). The technology has to withstand this constant exposure to nature and function reliably – for years, for the whole service life of the wind turbine. "In our new Test and Prototype Center, we will be able to simulate all the loads that occur on site," explains Geens. The test bench can also be used to test the reliability of complex powertrains under extreme conditions. In future, engineers will be able to determine more quickly and easily whether a new generation of gearboxes or components will function permanently or not. This means that new wind power technology can be launched on the market faster, be more reliable and thus help accelerate the energy transition.

"For me, the best thing about Test & Validation is that I’m involved right from the start,” says Geens. "I start with a blank sheet of paper and can help develop everything right up to the final test setup in the production hall. This is what motivates me – especially when unexpected obstacles arise during implementation that I hadn’t seen previously at my desk." To comprehensively determine the reliability of components and systems – that is the core task of this XXL test bench. ZF uses these test runs to minimize risks in the wind industry. They are also the prerequisite for obtaining the approval from customers, insurers and the certification authorities in order to bring new wind turbine designs to the market in the first place.

Overcoming obstacles and finding solutions is what motivates Wim Geens in his work.

But back to Wim Geens. Today’s test specialist Geens laid the foundation for his career by attending a school for electromechanical engineering and specializing in technical drawing. He then worked as an assistant in the technical design department at the former Hansen Transmissions company, which ZF took over in 2011 and transformed into ZF Wind Power.

The manufacturer of wind turbine gearboxes and powertrains currently employs around 4,000 colleagues in Europe, China, India and the USA. To date, ZF Wind Power has delivered more than 80,000 gearboxes with an electrical production capacity of 180 gigawatts. This is enough to supply more than 150 million households with electricity. Every fourth wind turbine gearbox in the world now comes from ZF Wind Power.

"The opportunities for me at ZF are very interesting. I started out as a drafter, then I was able to work with customers in sales as a technical consultant and today I am responsible for setting up the no-load tests."

For Geens, good cooperation is crucial.

He still benefits from his old contacts in the various departments today. For Geens, good cooperation is crucial, as only working towards a common goal is motivating and fun.

For him and his team, the customer is king. "Once," Geens recalls, "we built a cold chamber for a customer to simulate conditions similar to those at the North Pole. That was the only way we could carry out all the necessary tests. This teamwork motivates me every day." For Geens, one thing is clear: what works at a small scale can also provide the solution for large tasks. "To make faster progress in the use of renewable energies, we need more cooperation between countries worldwide. Not everyone is on board yet, but we need everyone to empower a sustainable future."