Make Your Supply Chain Greener now

ZF needs to and is willing to reduce its carbon footprint in order to become carbon neutral in 2040. Purchased materials such as steel play an important role in this context. The following is a glance behind the scenes.

High in the north of Sweden, less than 100 kilometers from the Arctic Circle, a new industrial revolution is being born. Here, near the small town of Boden, the start-up Stegra is currently building a new steel-mill. This steel-mill is special. From the year 2026 onwards, it will produce so-called green steel. The smelting process itself will take place inside electric arc furnaces powered by sustainably generated electricity and utilizing green hydrogen. During the reduction process, the latter replaces conventional common coking coal, which is extremely harmful to the environment. Compared to the traditional process, carbon emissions at Stegra are reduced by up to 95 percent. Reason enough for ZF to order 250,000 tons of this almost carbon neutral steel delivered every year until 2033. This quantity covers approximately one tenth of the total demand by ZF in 2021.

Carbon Neutrality: All Activities Checked

The conclusion of this contract between the two companies in the spring of 2022 signals a major step forward towards ZF's plans for carbon neutrality by 2040. This will only be possible if not only the company's own activities are carbon neutral, but also all purchased raw materials, their precursors and of course the necessary energy. ZF pursues different approaches to reduce emissions in the downstream value-added chain. “For one, we are working with our suppliers to switch to materials or technologies that emit less carbon. But we are also putting a fresh emphasis on the issue of producing electricity from renewable sources, as we regard clean electricity as a decisive lever to achieve decarbonization,” says Michael Schmitt, Vice President Supplier Management and Sustainability. His sustainability team from Materials Management defines binding sustainability requirements for suppliers of a wide array of varied materials and for suppliers of energy.

Steel: Versatility at a Heavy Cost

According to the global association Worldsteel, the global industry produced 1.95 billion tons of steel in the year 2021. This makes the production of steel responsible for seven to nine percent of direct emissions of CO2. Following the construction sector, the automotive industry is the largest purchaser of steel. Every year, the ZF Group directly or indirectly processes approximately 2.5 million tons of this versatile material. Steel is extremely resistant yet shapeable and can also be infinitely recycled. However, its many advantages must be weighed against one considerable disadvantage: Steel comes with a huge cost in emissions.

Manufactured the traditional way inside a classic blast furnace, the production of a single ton of steel generates more than 1.8 tons of carbon dioxide. The procedure utilized by the new supplier Stegra, however, avoids 95 percent of carbon emissions. Their process of steel production mostly generates nothing but harmless steam as a byproduct. “Our goal is to address key issues early on and together with suppliers such as Stegra, to drive the development of innovative steel products and solutions. It is one of our top priorities to further reduce the carbon footprint of our products,” says Matthias Lang, Vice President Production Materials, Steel Components.

Solutions Through Supplier Partnership

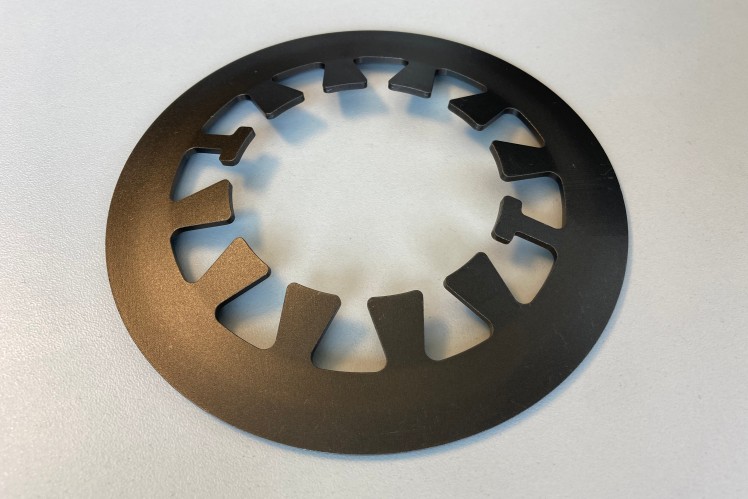

Other than cooperating with new partners, ZF also supports its existing suppliers in their development towards a more sustainable production. For example, towards the year of 2021 the technological company embarked on a pilot project with Mubea Tellerfeder GmbH. Both sides investigated which of the transmission disk springs already being produced in volume production and supplied to ZF for years would be suitable for a sustainability project.

Example of a transmission disk spring made of green steel, as it is currently being examined by ZF experts.

Finally, the participants identified two suitable types. In a next step, they determined the product carbon footprint (PCF) for the two transmission disk springs using the current production method. In close cooperation with ZF as the customer, Mubea subsequently converted the manufacturing process for the steel used within the pilot project to “green steel”. At the end of January 2023, Mubea delivered the first manufacturing batch of the “green” transmission disk springs to ZF for an expert opinion.

Metals dealer Klöckner & Co SE has also recognized the signs of the time and acts accordingly. The Duisburg-based company offers its customers over 200,000 products with individually calculated product carbon footprint (PCF). Customers like ZF use such PCF information to improve their transparency. Since the end of January 2023, the Klöckner Group subsidiary Becker Stahl-Service also supplies the PCF for selected parts in the flat steel sector.

First Movers Coalition

Voluntary Promotion of Carbon Neutrality

As one of more than 60 large companies worldwide, ZF is a founding member of the “First Movers Coalition” (FMC). Founded in 2021, the FCM is a partnership between the World Economic Forum and the U.S. Special Presidential Envoy for Climate, John Kerry. The task of the First Movers Coalition is to massively advance the development and use of urgently needed carbon reducing technologies in different areas of application. Until the year 2030, the members of this coalition have pledged to purchase as many zero-emission goods and services as possible. This is intended to stimulate the demand for low-carbon technologies, make them capable of competing and lead to the establishment of clean supply chains for the future. Upon joining, ZF made a purchase promise for the “Steel” sector. With the large order for steel from Stegra, ZF will already begin to fulfil its FMC promise in the year 2025. This makes ZF a pioneer.