ZF Aftermarket in Liberec

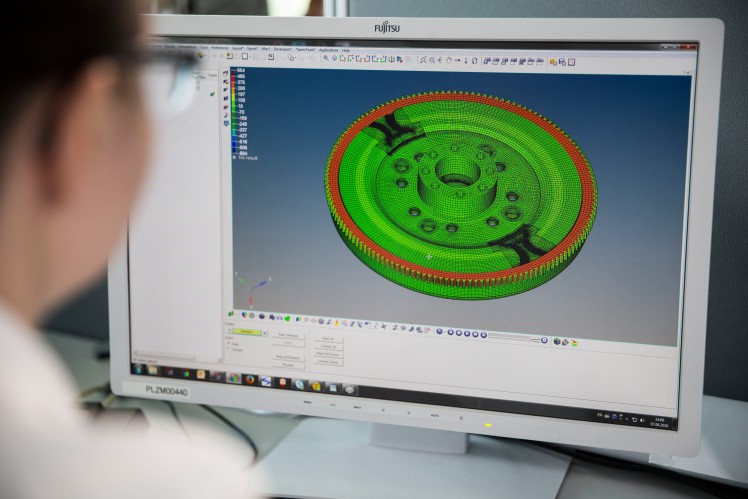

The new ZF Liberec development centre was established due to insufficient capacity to accommodate the test beds in Jablonec nad Nisou. Part of the Jablonec development was moved to Liberec. In the renovated premises, facilities were created for several development departments, namely the driving test department, the noise measurement department and also the HiL laboratory for virtual driving test simulations. By the end of 2023, the Fatigue department will also move in to conduct fatigue tests on resonators. There is also a large garage for preparing test cars for driving tests and an E-lab for preparing the installation of measuring technology in the cars.

- The branch in Liberec is part of ZF Automotive Czech

- It was founded in 2023 and currently has 50 employees

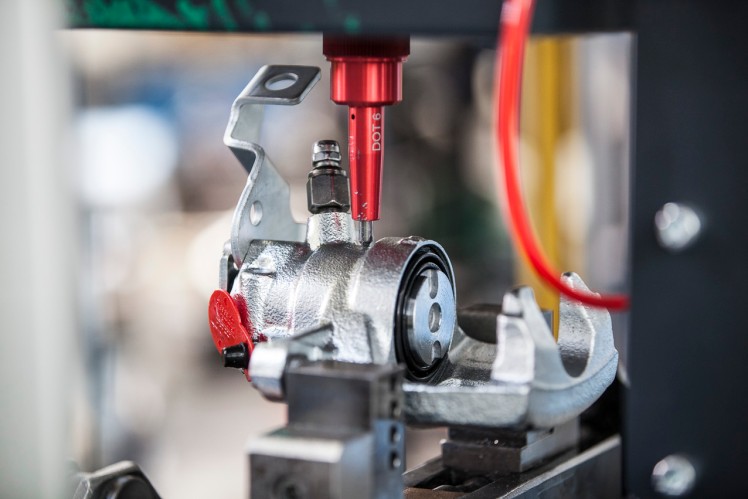

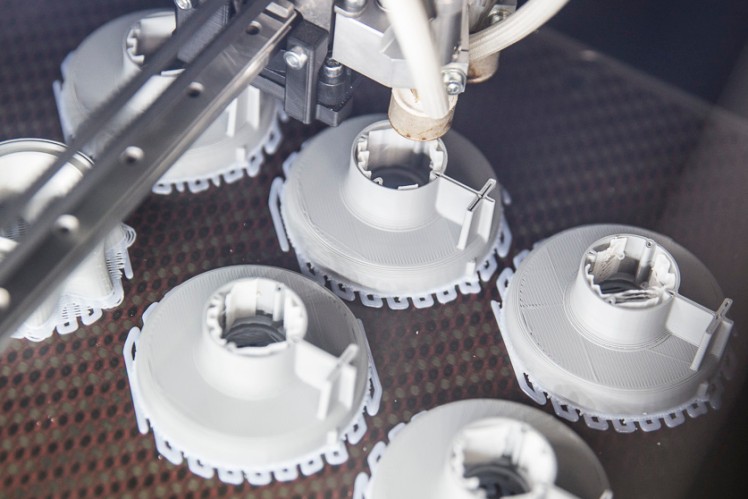

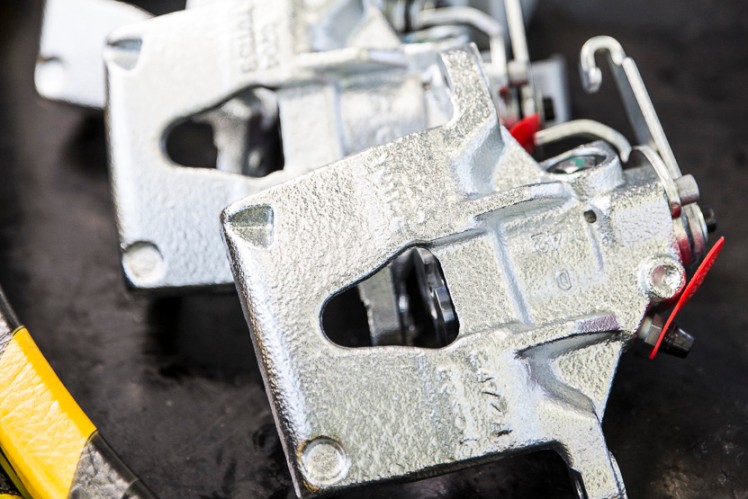

- The main areas of development include design and testing of brake system components, testing and verification of brake system components on test benches and directly in cars on test circuits.

- The branch also develops and tests brake master cylinders with brake fluid reservoirs, EBC units and IBC units (a more modern and sophisticated replacement for the brake booster, master cylinder and ABS and ESP units), necessary for regenerative braking, front and rear disc brakes, including electric parking brakes.