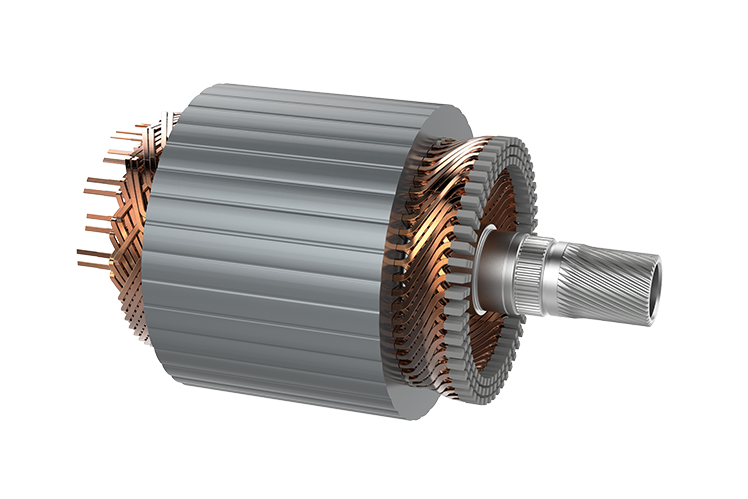

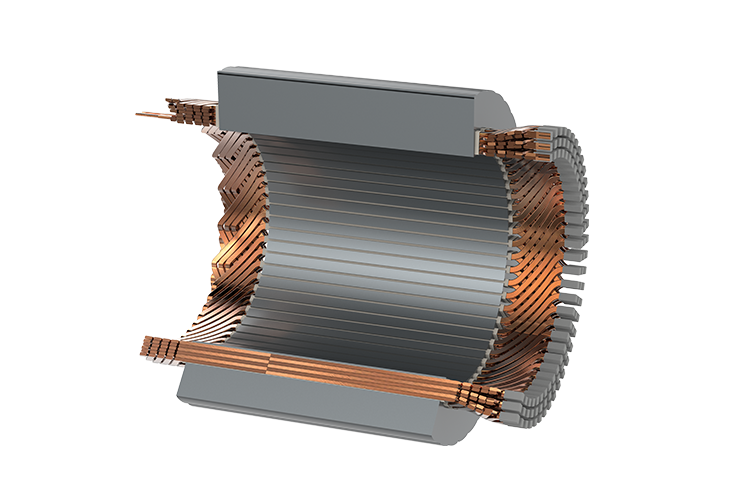

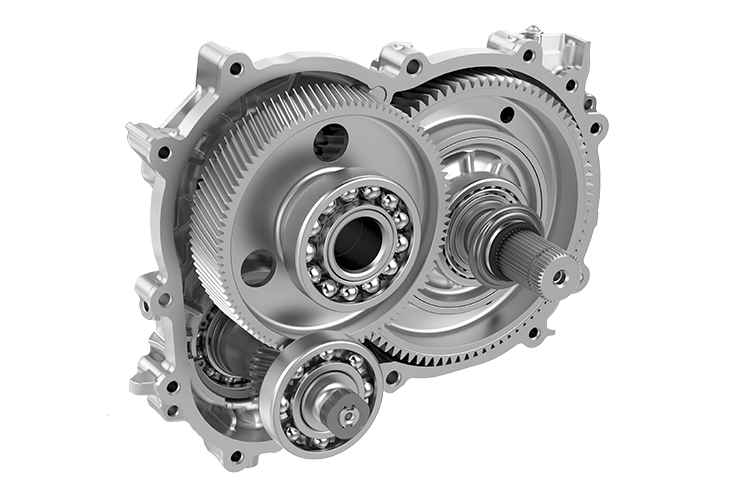

Vehicle manufacturers have different ideas about the e-drive system, depending on whether they are designing a BEV as a sports car, a saloon, an SUV or a small, economical car. As the different requirements grow, so does the total number of e-drive systems needed.

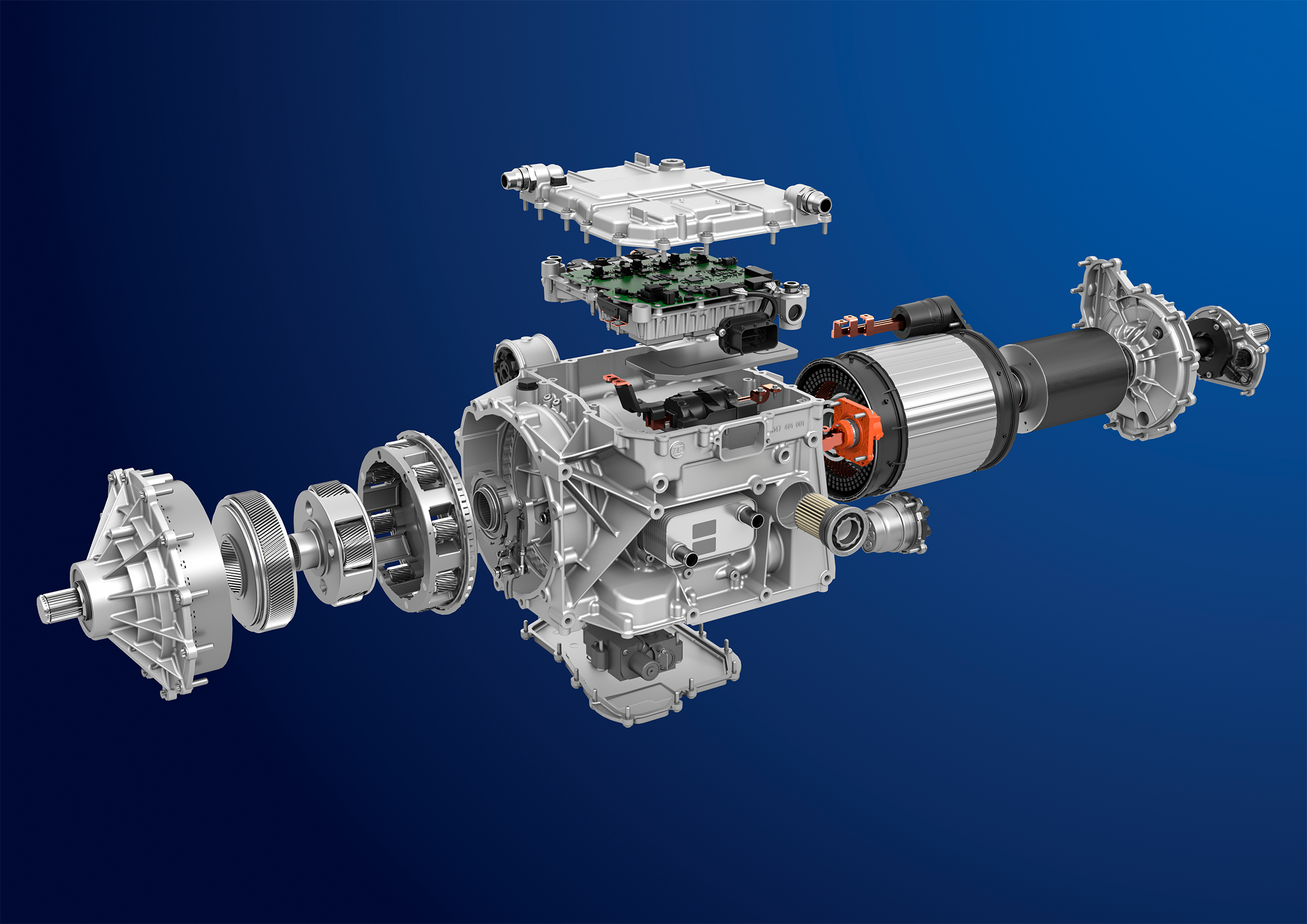

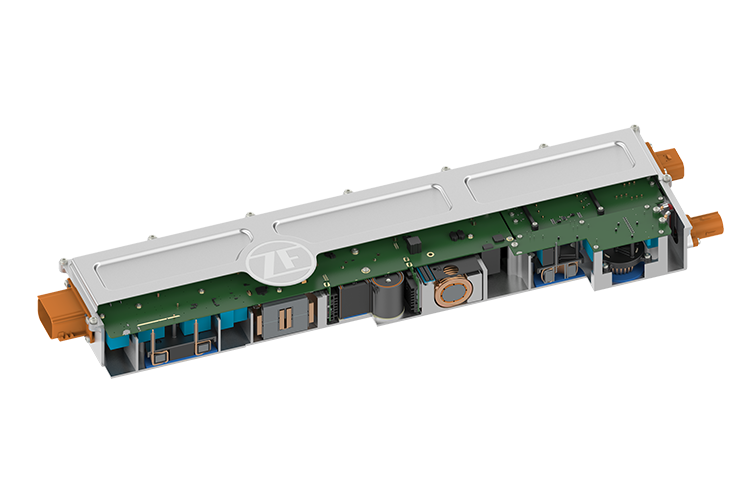

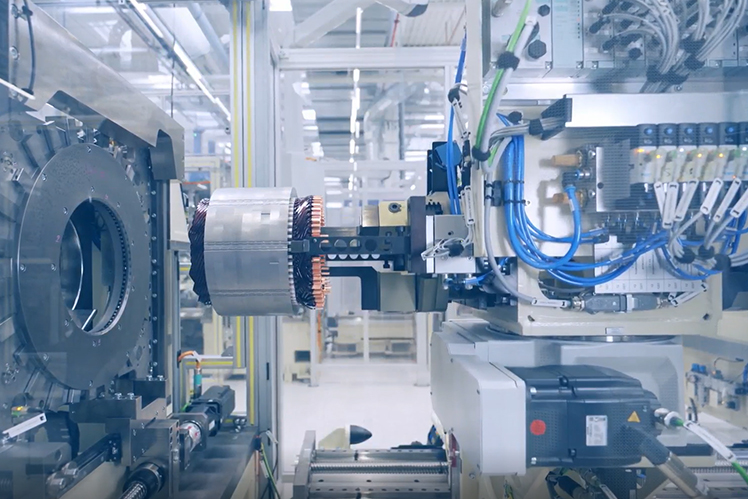

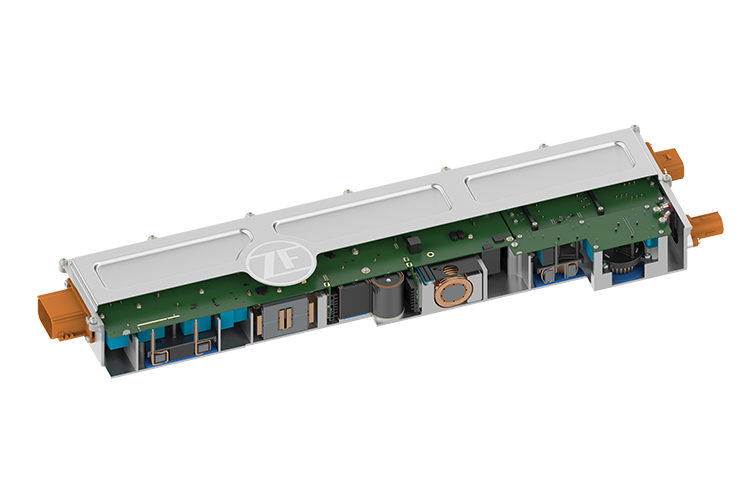

Our platform approach, the ZF eDrive platform SELECT, offers precisely this flexibility in e-drive - but without increasing complexity, effort and ultimately development time and costs. Dr. Fabio Dohr explains how this works in this video.