Transmitter modules transmit data from critical components such as transmission oil or clutch disks to the OEM's cloud. The vehicle manufacturer's data platform is in contact with the ZF IoT platform. The latter has the ability to take the primary data it has received and compile reports on the condition of the transmission components. These can then be read by the OEM or fleet operator and used to proactively plan maintenance.

Technology

#Digitalization

IoT – A Network of New Possibilities

Min Reading Time

From smart hardware systems to digital services: With its cloud-based IoT platform, ZF offers its customers a wide range of innovative, secure and intelligent solutions – across a range of applications and industries.

By 2025, all ZF products will be networked

By 2025, all ZF products will be networked

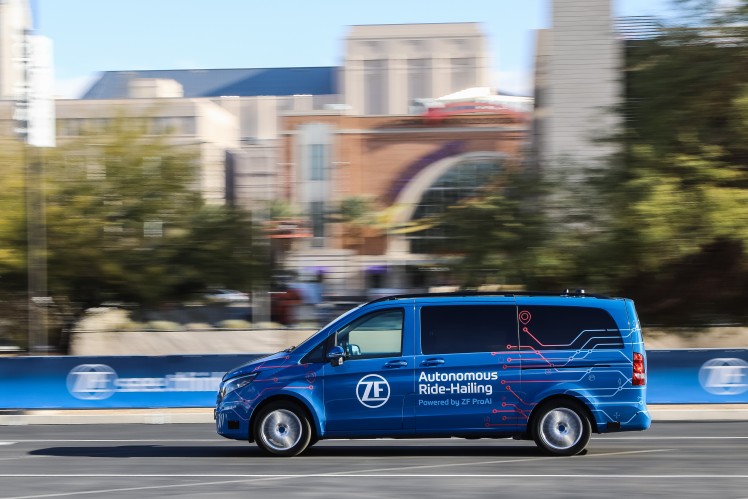

"System networking has always been one of ZF's core competencies – be it using transmission data for remote diagnosis or the automation of production processes," says Mamatha Chamarthi, Chief Digital Officer (CDO) of ZF. "We want to expand this: By 2025, all our products will be networked." A decisive basis for this is the open ZF IoT platform based on Microsoft Azure. It enables new digital services to be implemented and hardware systems to be used efficiently through data analysis and smart algorithms. Thanks to its broad portfolio, ZF can also leverage the platform to analyse data trends across industries and form synergies. The Group’s IoT platform already combines various functions across a wide range of applications and industries in order to provide its customers with innovative, safe, and intelligent solutions.

"By 2025, all of our products will be networked."

Networked Solutions for Future Mobility

With its open system

Openmatics

, ZF has long established itself as a telematics provider. In addition to conventional fleet management, the connectivity platform includes extensive functions for the owners of electric vehicles. Electric bus manufacturer VDL relies on this solution. The Dutch city bus and coach manufacturer now equips many of its commercial vehicles ex works with the Openmatics open connectivity platform. In particular, it enables VDL to maintain a complete overview of the operational efficiency of its vehicles.

Moreover, Openmatics is expanding its portfolio with the ZF Car Connect solution for fleet operators. It is also based on the ZF IoT platform and includes a mobile app for drivers with a digital logbook function along with the web-based portal for fleet managers.

Cloud for Automated Driving

Automated driving functions are continually increasing and require regular software updates to ensure efficiency, traffic safety and cyber protection. Here, the ZF IoT platform will play an important role as an interface for over-the-air (OTA) updates. To further advance this technology, ZF has joined the eSync Alliance. It is working on a globally uniform and manufacturer-independent standard for OTA updates. The eSync system ensures that data is securely exchanged between the cloud and electronic terminal units and helps to protect the vehicle’s cyber architecture from hacker attacks.

Three Examples of Smart Industry 4.0 Solutions

Based on the open IoT platform, ZF has developed a large number of innovative Industry 4.0 solutions:

- deTAGtive Asset Tracking: Bluetooth tags are an essential part of this asset tracking system – small wireless Bluetooth units that track materials and goods in factories, depots and warehouses throughout the entire supply chain. Video: How deTAGtive works

- ZF Call Button: Thanks to this interactive intralogistics innovation, supplies are delivered to the workplace at the touch of a button. No cables, no additional devices and easy to set up, the Call Button adapts flexibly to any production environment or warehouse administration system.

- CERA: ZF itself uses the CERA (Connected End-of-Line Reject Analyzer) quality management tool in manufacturing steering columns: If the product shows errors during the final functional test, CERA can compare the malfunction with the production data in real time. This allows the source of the error to be identified quickly and rectified before major expenses are incurred.