Test and Validation

Independent expertise in Test and Validation supports customers in product development, production and validation functions world-wide. Technical Specialists and in-house UKAS-accredited test facilities give us a unique capability to provide full engineering services from concept design, development and prototyping to testing and evaluation.

This accreditation, awarded by the United Kingdom Accreditation Service (UKAS), validates our technical expertise and confirms that our testing facilities operate to internationally recognized standards. Whether you are in the automotive, aerospace or any other industry,you can trust our results to meet and exceed global compliance requirements. Our UKAS-accredited lab ensures that your products undergo testing with the highest degree of precision and accuracy. This speeds up your product development cycles, ensuring faster time-to-market without compromising on safety or performance.

As UKAS Test Laboratory No. 0332, ZF Automotive UK Limited - the ZES UK designation - provides comprehensive testing solutions, including mechanical, environmental, EMC and safety testing. This enables us to support you across the entire product life cycle, from concept through to final validation.

Whether you are working on complex automotive engineering projects or aerospace advancements, our accredited testing services are tailored to your unique requirements, ensuring your products excel in real-world conditions.

EMC Testing

A whole suite of EMC tests can be performed on one site, including radiated EMC testing in semi-anechoic chambers and conducted EMC and transient testing in specially screened rooms.

Climatics

Our climatic environmental testing capabilities encompass a wide range of assessments designed to ensure durability and performance under extreme conditions.This includes extreme climatic conditions, ranging from desert dryness and dust to damp tropical heat and sub-zero temperatures.

Vibration

Our vibration environmental testing capabilities cover a comprehensive range of evaluations to ensure reliability under dynamic conditions. These include vibration measurement and frequency analysis, as well as various test types such as Sine, Random, Sine-on-Random, Gunfire, Shock, and Bump.

Materials Testing

ZES provides reliability and materials analysis services to enable its clients to improve the operating performance and integrity of electronic and electromechanical products.

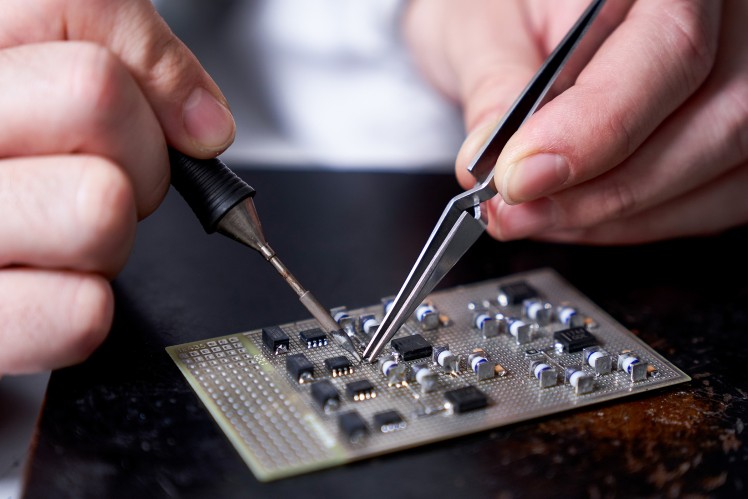

Prototyping and Instrumentation

We are able to apply creativity and prototyping skills to many different engineering applications in order to convert a need or an idea into a physical reality. Work can be performed from a wide range of requirements specifications - including verbal descriptions, sketches, engineering drawings and CAD files.

Testing and validation of products is critical at each stage of product development to ensure the safe and efficient path to product launch. With ISO 17025 accreditation (UKAS Testing Laboratory 0332), we are highly experienced in the areas of EMC validation, environmental testing, instrumentation, advanced validation and prototype design and manufacture.