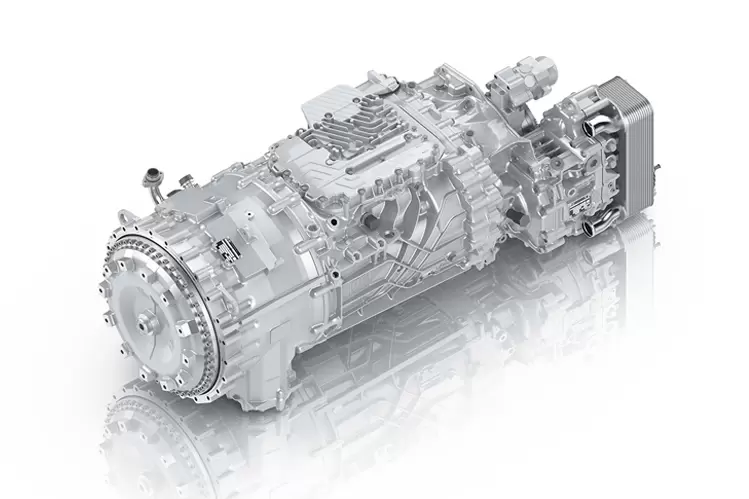

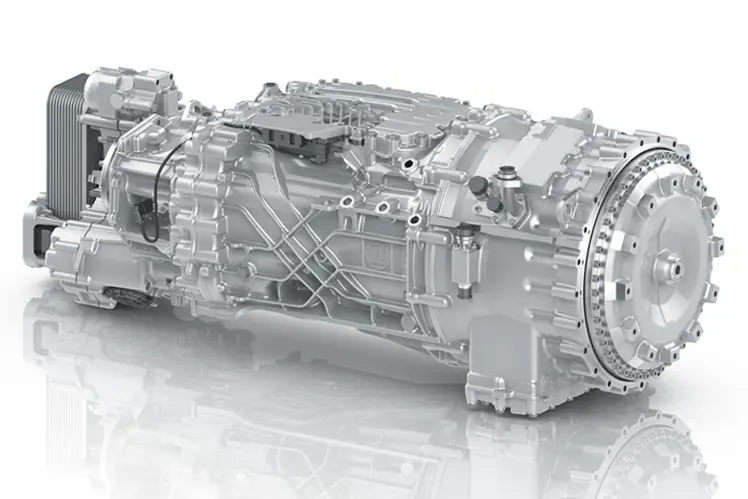

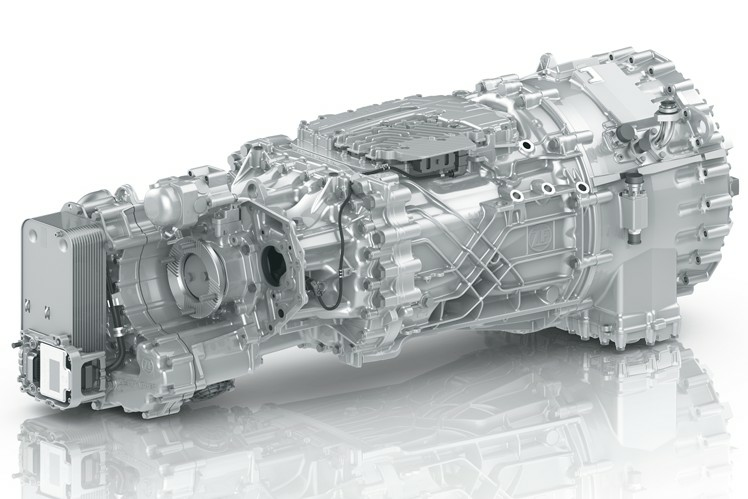

TraXon Torque 2-TraXon 2 & Torque Converter Clutch

Best combination of two technologies

TraXon Torque is the module for wear-free setting off with heavy transport vehicles and stands for smooth and comfortable maneuvering at low life cycle cos

Key Facts

What can TraXon Torque 2-TraXon 2 & Torque Converter Clutch provide?

When heavy equipment is used, the torque converter clutch is the best choice to get things moving quickly and smoothly; also for the driveline. In the TraXon Torque 2 the TraXon 2 transmission is combined with a torque converter clutch as the starting component. Setting off and maneuvering is comfortable even when very high input torques are transmitted, without jerking or wear – thanks to the hydrodynamic torque converter.

Details

Benefits & advantages

- Higher torque possible – thanks to torque increase when setting off or when opening the lock-up clutch in extreme situations

- Setting off on steep gradients and driving uphill at higher speeds is possible

- Boost mode in extreme situations

Torque converter lock-up during travel and zero-wear shifting and clutch actuation with the basic transmission

- Clutch protection by slip monitoring

- Low operation, maintenance and life-cycle costs

- High brake force and long service life of service brakes

- High system availability and long service life

- Optionally available: wading capability

Function

In comparison to a normal dry clutch, the torque converter clutch (TCC) increases starting torques. It is made up by an oil-filled hydraulic torque converter, the associated torque converter lock-up clutch, and a downstream dry clutch.

Learn more about how it works in the video.