ELECTRIFICATION

The trend towards electromobility is not confined to passenger cars. Thanks to ZF technology, work on urban construction sites and in buildings will also be possible in the future - despite strict standards concerning emissions: ZF takes care of climate-friendly operation, neutral in terms of CO₂ emissions and offers E-Mobily Solutions for various applications.

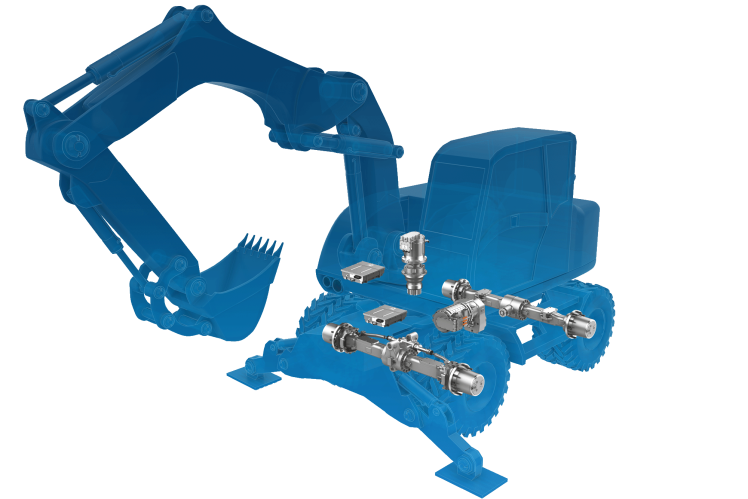

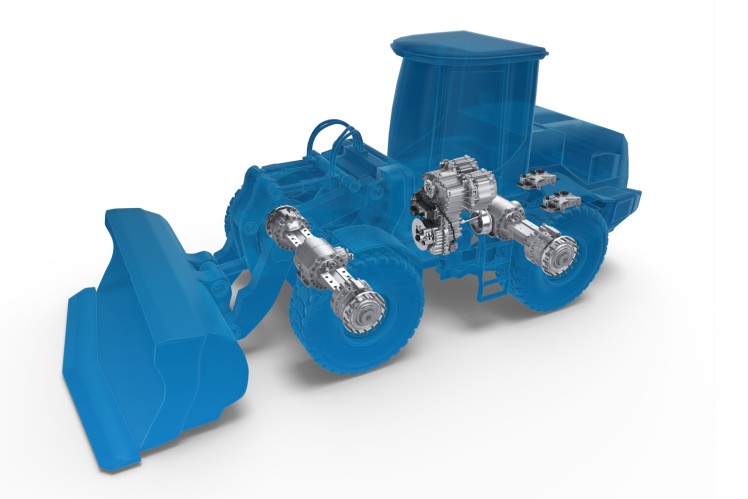

Electric Compact Vehicles

Emission-free and eco-friendly

Guided by the principle of zero emissions, ZF strives to enable compact work machinery to operate completely emission-free in the future.

Being a systems supplier, ZF not only delivers the unit, but offers a combination of front and rear axles, drives, inverters and electric Drive Control Unit.

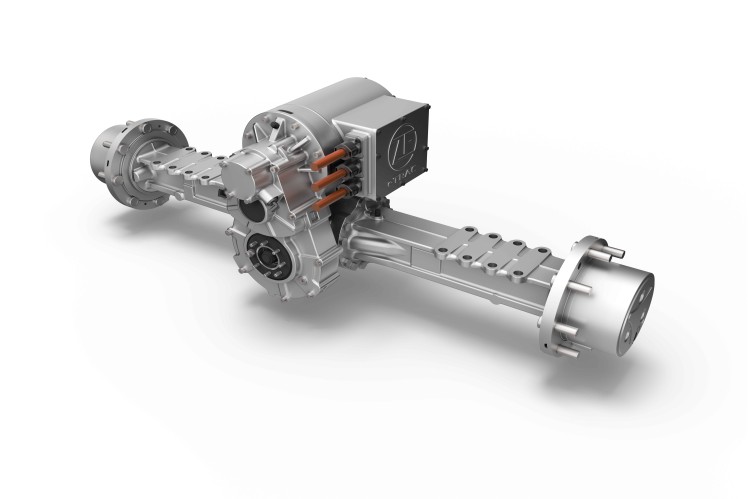

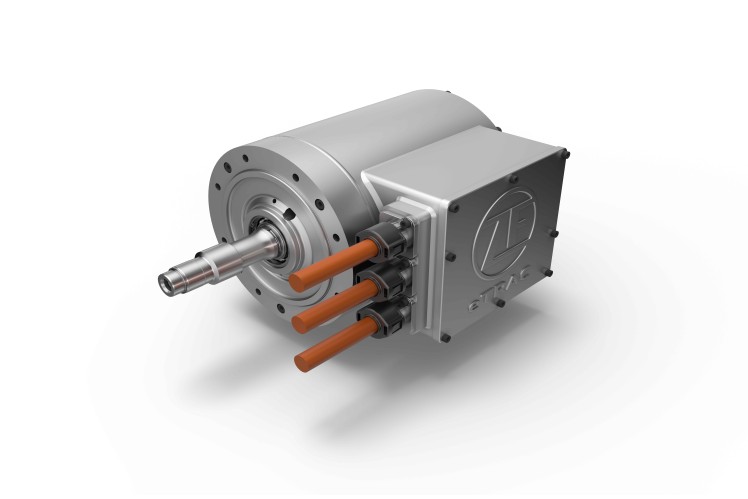

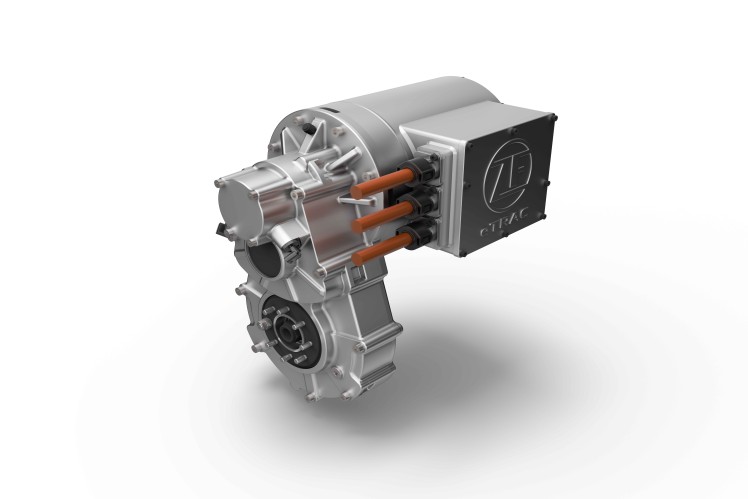

eTRAC

Electric Central Drive

The electrified eTRAC driveline system with its 48-volt electric motor developed by ZF provides the necessary emission-free drive.

Advantages:

- A "best in class solution" for power density in compact loaders

- Unrivalled on the market in the 20 kW (continuous performance) and 48 V performance classes

- Use of liquid coolant in the traction motor and power electronics ensures continued performance in construction machinery applications

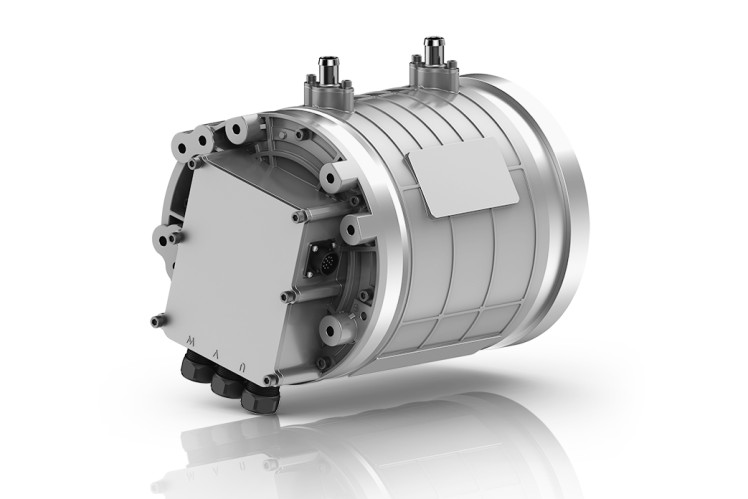

Power Electronics

Standard power electronics adapted for off-highway and commercial vehicle technology

Advantages

- Liquid cooling

- Parameterization of the power electronics according to the characteristics of the ZF e-machinery

- Modular use of the software for low-voltage and high-voltage power electronics

- Torque and speed control via CAN protocol

Standard power electronics adapted for off-highway (48 V) and commercial vehicle technology (650 V).

eHydraulics

Electric motor with a flange-mounted hydraulic pump which conveys a constant volume

Advantages

- Power on demand

- Needs-oriented flow rate

- Reduced idling losses

- Reduced throttling losses

Electric motor with a flange-mounted hydraulic pump

| Nominal DC supply | 48 V | 650 V | 650 V |

|---|---|---|---|

| Maximum speed | 4000 rpm | 4000 rpm | 4000 rpm |

| Maximum power (S3-15 %) | 30 kW | 37 kW | 42 kW |

| Pressure | 250 bar | 250 bar | 250 bar |

| Flow | 63 l/min | 79 l/min | 90 l/min |

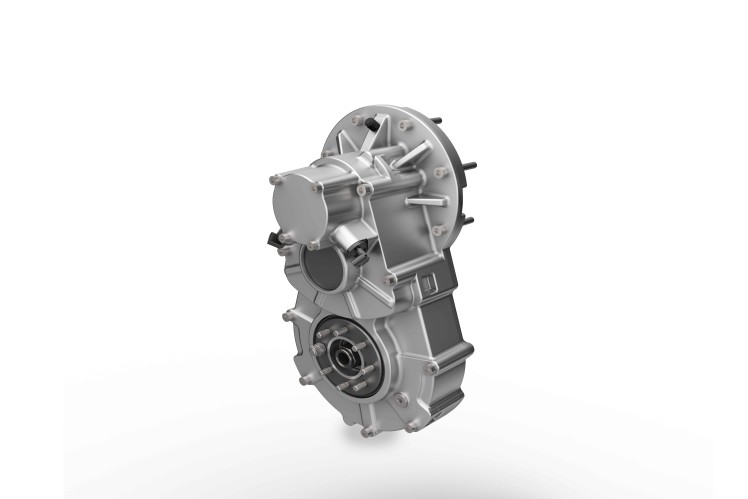

Electronic Drive Control Unit (eDCU)

Electronic control unit for travel drive and hydraulic drive

Advantages

- Communication via CAN with power electronics

- Operating strategy for load sensing (torque sensitive) travel drive and hydraulic drive

- Performance management for combined operation of both drives

- Extended with safety functions to ensure requirements from off-highway

eDCU: Electronic control unit for travel and hydraulic drive