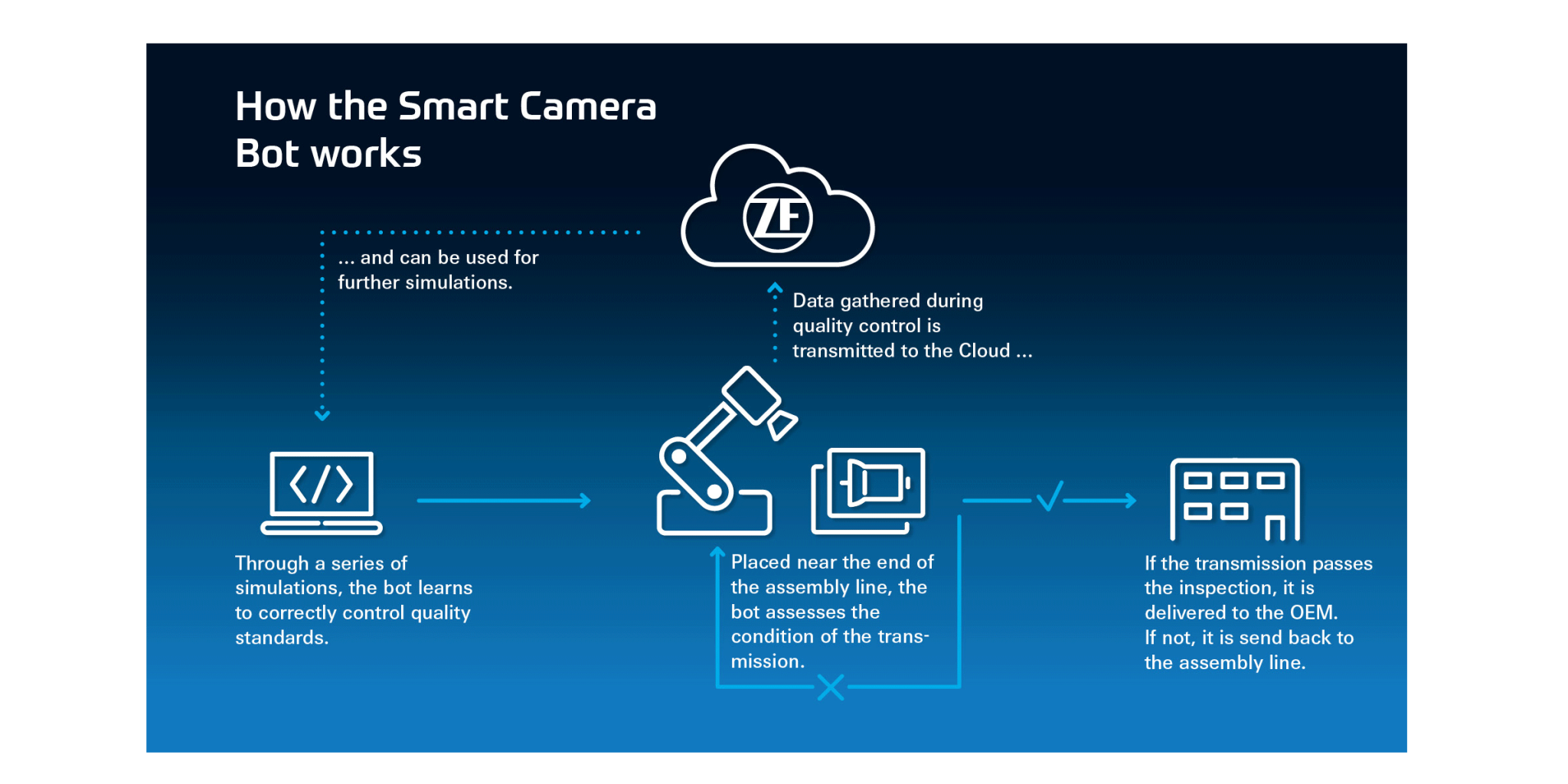

At the Saarbrücken plant, around 10,000 transmissions of different types roll off the assembly line every day. Each part passes through several levels of quality assurance before it is delivered to the OEM customer. One of these levels is a visual check: Are all connections wired correctly? Are protective caps in the right place? Do these protective caps have the right colors? Is the paint intact?

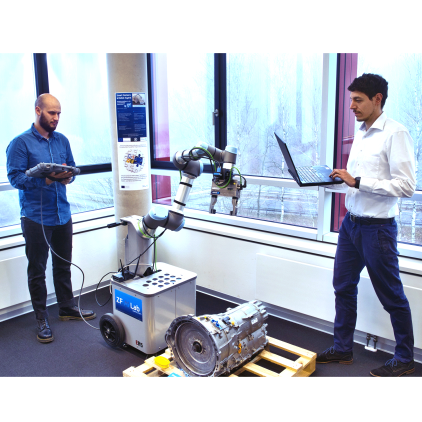

This is exactly the kind of task in which a digital brain can do better than the human brain. "Our Smart Camera Bot can take over this monotonous task and thus optimally relieve the colleagues," says Masiak. The prototype consists of a small wheeled platform for maneuvering, a multi-articulated arm with a camera attached to it – and powerful algorithms, which enable the bot to perform the quality assurance tasks independently and automatically. For the "Smart Camera & Robot Agent" research project, the AI Lab recently received a grant from the Saarland State Chancellery and the EU's European Regional Development Fund.