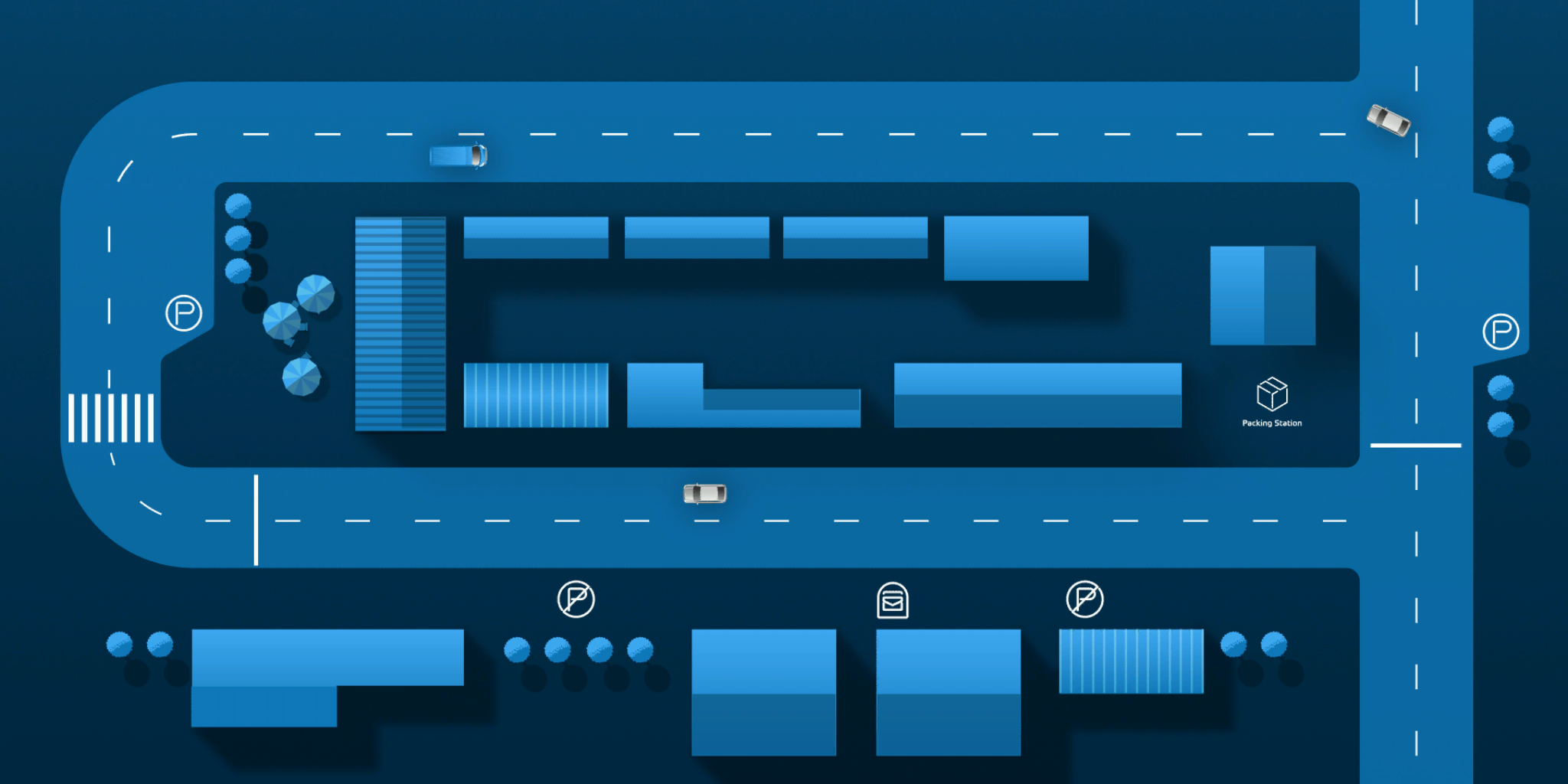

Downtimes increase operating costs for fleet operators - ZF's predictive maintenance function adjusts maintenance intervals to actual use, thus avoiding unnecessary costs.

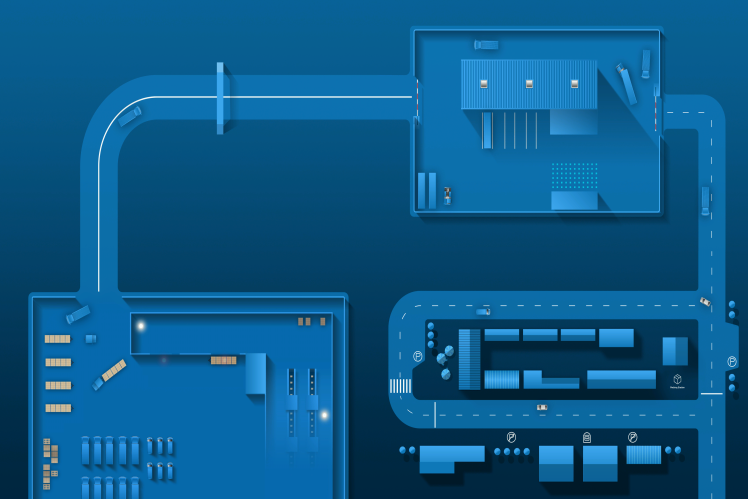

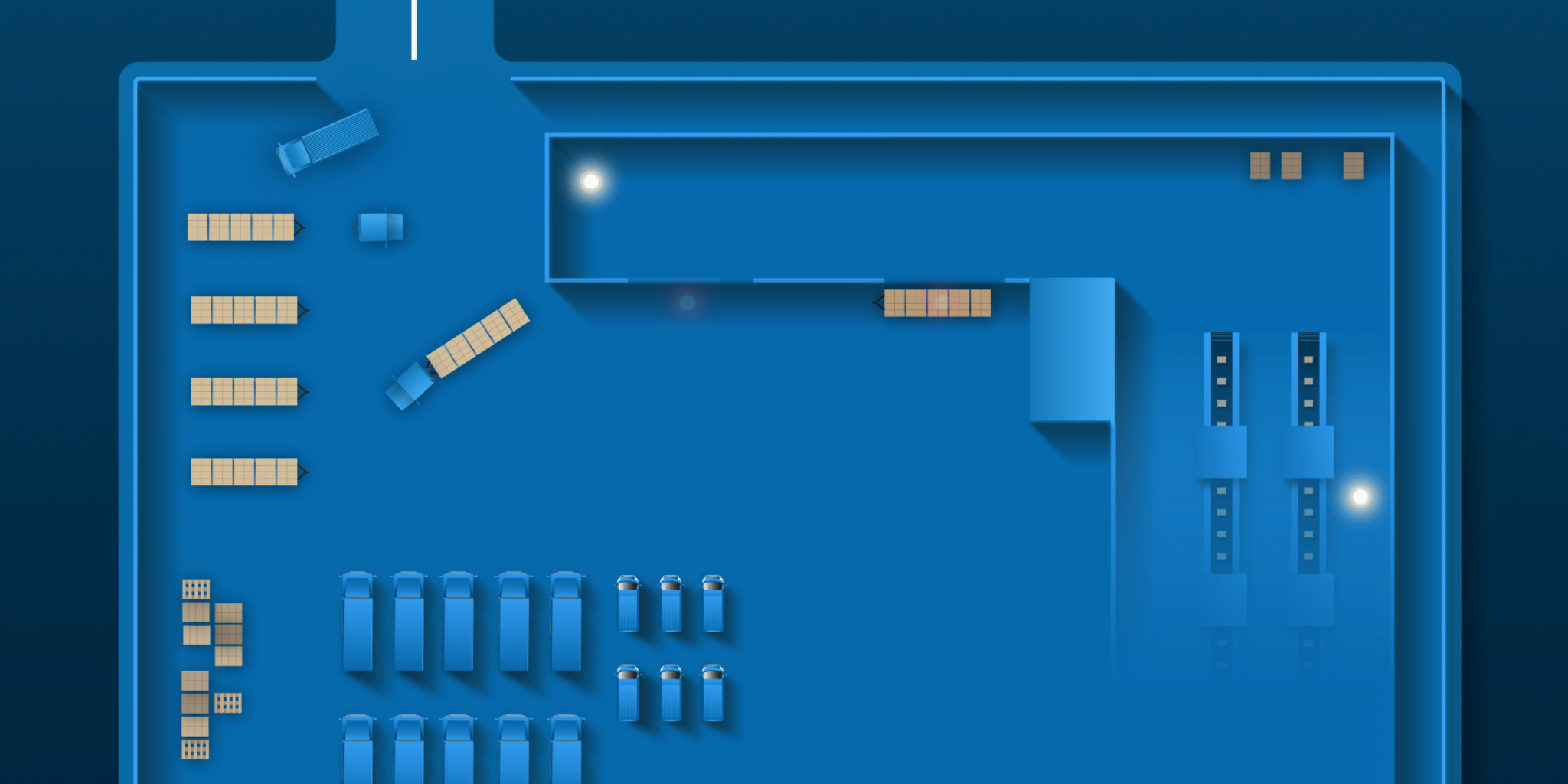

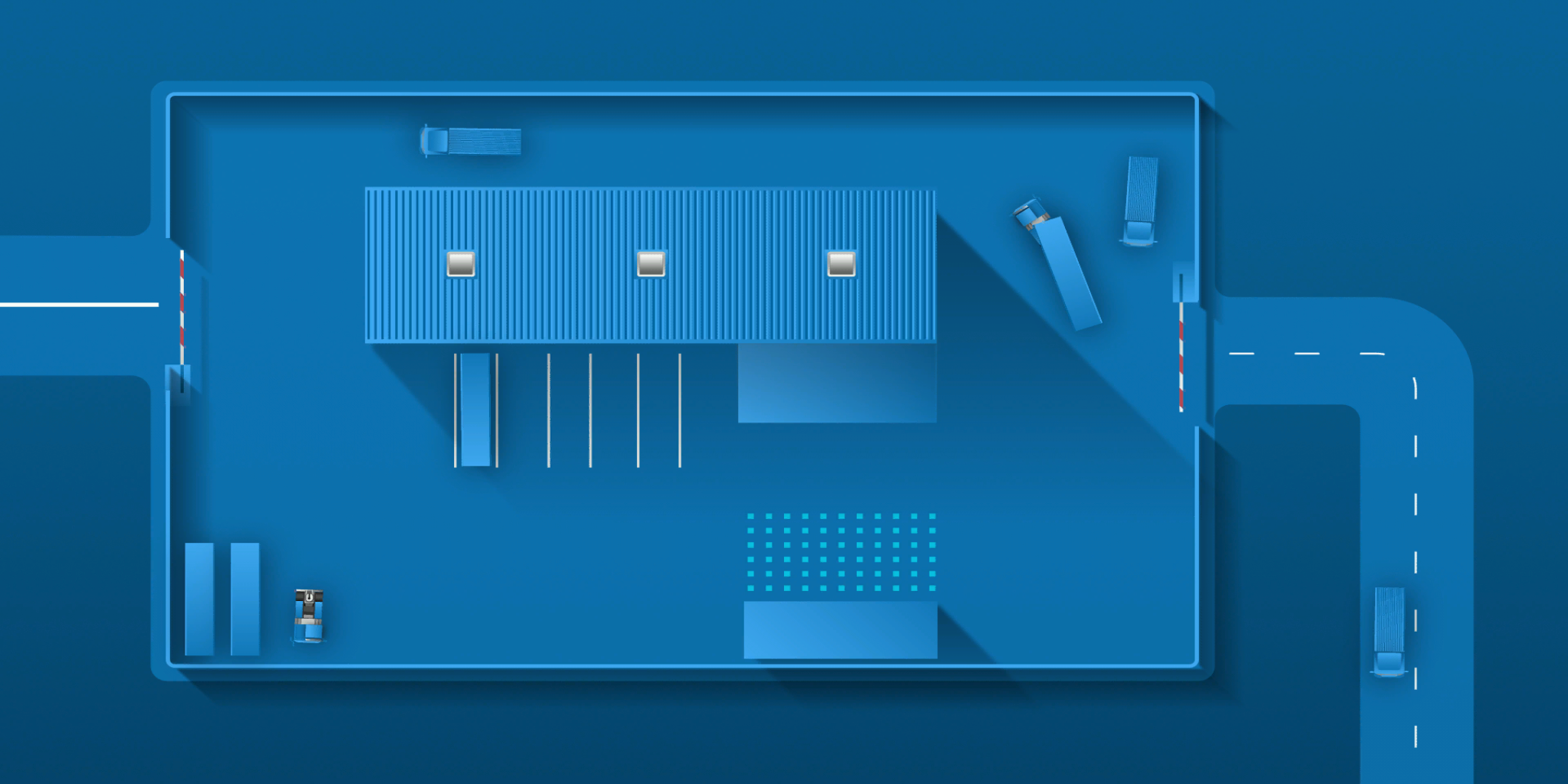

With predictive maintenance, the suitable vehicle is automatically selected for new transport orders. The maintenance history and the condition of the vehicle play a decisive role here. If the new order involves a transport distance of 5,000 kilometers, for example, a vehicle is selected that requires neither oil changes nor maintenance within this distance.

ZF's predictive maintenance function does not check the condition of the vehicles on the basis of mileage and maintenance intervals. The system constantly monitors the transmission oil as well as the clutch disc. In this way, it can make forecasts about a due transmission oil change as well as for the remaining service life of the clutch disc. The truck's suitability for the upcoming transport job depends on this.

If, for example, the clutch disc has a remaining service life of 3,000 kilometers, a transport order of 5,000 kilometers can result in an acute risk of breakdown. In this case, the ZF predictive maintenance system arranges a service appointment and places the order with another vehicle.

Maintenance intervals are calculated in the ZF cloud in real time on the basis of actual usage data. Fleets benefit from longer service intervalls and less downtime - and a reduction in the Total Cost of Ownership (TCO).