From DIY Fascination to Engineering

I started my engineering journey at Budapest University of Technology and Economics, which later led to internships and a full-time job at ZF in Eger. Now, as a Simulation Engineer, I focus on Finite Element Analysis for e-mobility projects, finding fulfillment in the exciting challenges and a rewarding work-life balance.

My Journey into Engineering

My journey into engineering began at a young age. My father, an architect, and my grandfather, a mechanical engineer, both played influential roles. Additionally, my maternal grandfather worked as a welder. Growing up, I watched my grandfathers engage in various DIY projects, which fascinated me. Subconsciously, I was slowly turning into a future engineer.

I started my engineering studies at Budapest University of Technology and Economics, during my studies I developed interest in drive systems especially in vehicles, where ZF is a key manufacturer of transmissions. I discovered my path to ZF through a university job fair. A conversation about the daily work and company background with an Engineering Leader from ZF in Eger led me to apply for Summer Practice and later internship.

Summer Practice at ZF

In the Hungarian education system, a 6-week Summer Practice in the field is mandatory. In the summer of 2021, I had the opportunity to complete my practice at ZF. I chose ZF because I wanted to find a company where I could continue working after the practice. I thoroughly enjoyed my time there, getting to know the engineering teams. As part of the simulation engineering team, I delved into Finite Element Analysis. When the university program concluded, I received an offer to work as a Simulation Engineer Intern and a proposal of a thesis topic for the final exam. My expertise was growing steadily and as soon as I graduated, in January 2022, I progressed to the full-time job as Simulation Engineer, simultaneously starting a Master's degree in Mechanical Engineering.

Challenges and Impact

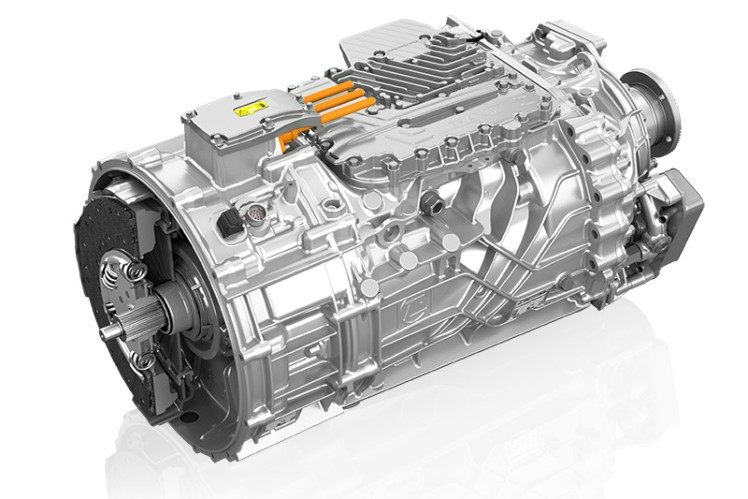

Now, at ZF Eger's Engineering Center, I work in a Team that specializes in Finite Element Simulations for Gearbox parts (Structural FEA, Fatigue analysis), aiming to contribute fast decision making before/after physical tests and to help the development of certain parts/products. My responsibilities span simulations for e-mobility projects like CeTrax, AxTrax and serial transmissions such as EL58 and TraXon. My daily routine involves meetings, data gathering, model construction, calculations, and result evaluations, varying in duration based on task intricacies.

At present I do calculations with TraXon Hybrid, among other ZF products

The most significant challenge of my job is to deliver results quickly but to always maintain high quality of my work. The responsibility is high because your assessment can alter the course of product development. Sometimes the solutions seem straightforward, but the process of implementing it into your simulations is not as simple. Yet, this constant challenge keeps me engaged, preventing any sense of routine. The learning curve remains steep, pushing my mind to operate at its fullest potential.

Seeing the direct impact of my work is exhilarating. When tasks change based on my conclusions and evaluations, it validates the value of my results. Additionally, the appreciation from my manager, who also serves as my mentor, motivates me further.

Essential Skills

To excel in my role, several key skills are essential. Firstly, a strong mechanical skillset is crucial. As a simulation engineer, translating real-life events into a virtual environment requires creativity and precision. An inherent interest in this field is equally important. Additionally, adaptability to rapid software changes is vital. While the theoretical background remains consistent, different software tools demand flexibility. It’s worth noting that not all software has identical menus, toolbars, or layouts. Moreover, determination and passion play a significant role due to the weighty responsibilities. Remaining open to new ideas and problem-solving methods, coupled with a constant thirst for learning, is essential. Lastly, proficiency in mechanical modeling ensures effective execution of tasks.

Professional and Personal Development

What truly excites me about working at ZF is the diverse range of challenges we face across various projects. Our working palette is vast, allowing us to continually learn and grow. ZF also supports my university studies by offering a flexible schedule, enabling me to balance work and education efficiently. Additionally, the company provides financial support for commuting costs. During crises, ZF’s stability and prompt response are commendable. For me, professional and personal development are extremely important, that is why I appreciate the free access to various courses, including those on the LinkedIn learning platform, internal trainings, and trips to other ZF technology centers abroad. Personally, I had the opportunity to attend a software training for Permas (Intes GmbH) in Stuttgart, Germany.

ZF in Three Words

If I were asked to describe ZF in three words, they would be: Development, Challenge, Future. ZF confronts technological challenges and develops the future of mobility, and I am proud to play a role.